Clearance angle grinding three-state positioning mechanism of gear grinding machine

A positioning mechanism and three-state technology, which is applied to positioning devices, metal processing mechanical parts, tool dressing of sawing machine devices, etc. The effect of saving manpower, improving grinding accuracy and fast grinding speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

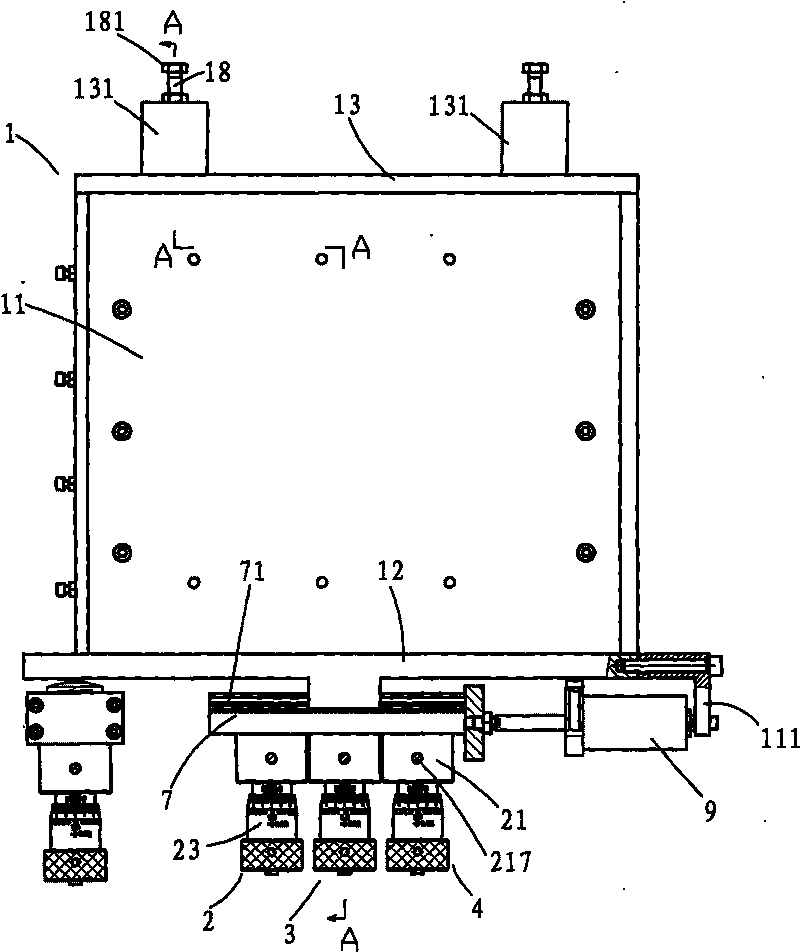

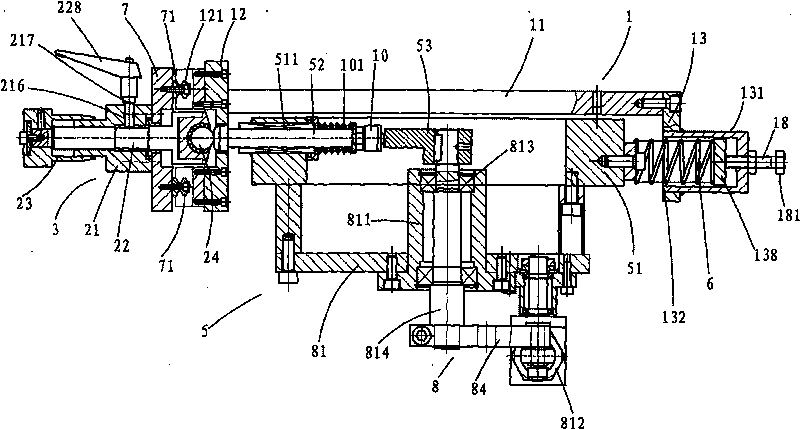

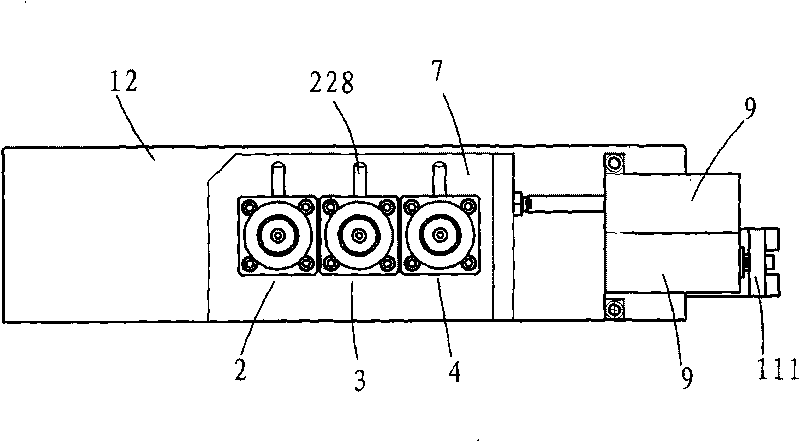

[0023] A three-state positioning mechanism for relief angle grinding of a gear grinding machine provided according to the present invention includes a workbench 1, first, second and third positioning devices 2, 3, 4 and The abutting device 5 located at the lower end of the workbench 1, the second positioning device 3 is 0.25 mm longer than the first positioning device 2, the third positioning device 4 is 1 / 3 tooth width longer than the second positioning device 3, and the abutting device 5 The rear end of the workbench is connected to the rear end of the workbench 1 through a pre-tension spring 6, and the front end only abuts against any one of the first, second, and third positioning devices 2, 3, and 4 each time. When working, the grinding device is installed on the workbench 1. When the abutment device 5 and the first positioning device 2 abut against each other, the low and flat teeth on the trapezoidal alloy circular saw blade can be ground. When the second positioning de...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com