Braking force regulator based on wire control braking system

A technology of brake-by-wire and braking force, applied in the direction of brake, brake transmission, transportation and packaging, etc., can solve the problems of many influencing factors, unstable braking, complex actuator, etc., to improve the reaction speed, reduce the body The effect of weight

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

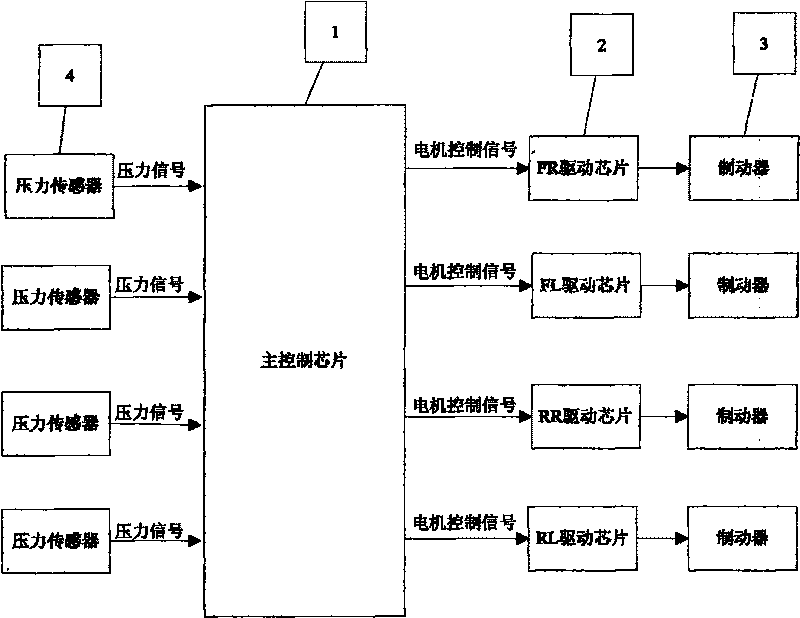

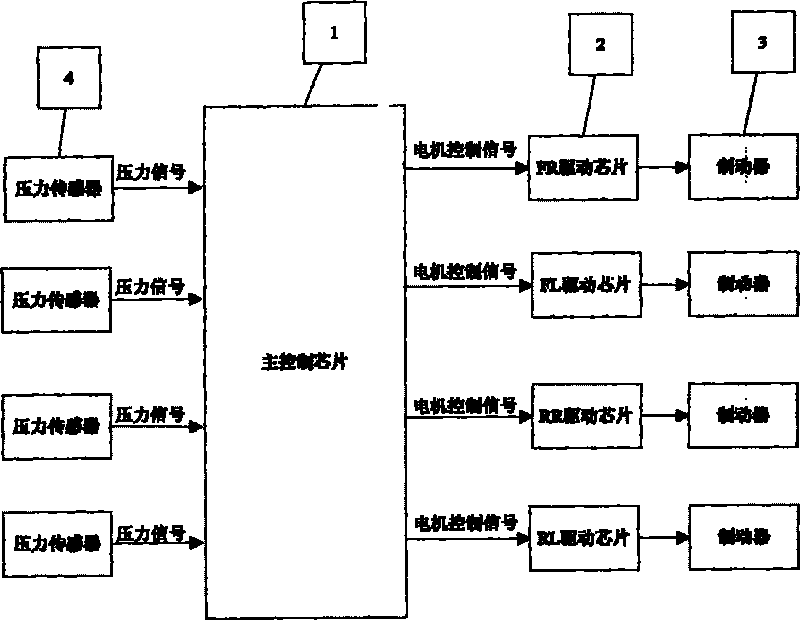

[0014] Such as figure 1 As shown, the regulator is mainly composed of a main control chip 1, a pressure sensor 4, a drive unit 2 and an electric brake 3. The main control chip 1 adopts the MPC5604P chip provided by FREESCALE, the pressure sensor 4 adopts Yongzheng load cell 266AH, the drive unit 2 adopts the BTN7960P chip of INFENION, and the electric brake 3 is a brake caliper with a built-in motor. Wherein, the pressure sensor 4 is installed on the friction plate, is connected with the main control chip 1 through the wiring harness, and transmits the pressure signal to the main control chip 1; Connect to receive the motor control signal sent by the main control chip 1; the electric brake 3 is installed on the original position of the brake caliper on the car, and the actuator integrated with the brake caliper replaces the original hydraulic brake caliper and is installed on the brake disc superior.

[0015] Utilizing the automobile braking force regulator of the present in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com