Hydraulic control system of beam transporting vehicle

A hydraulic control system and hydraulic system technology, which are used in the safety of fluid pressure actuation systems, vehicles for carrying long goods, fluid pressure actuation devices, etc. Economic losses and other issues, to achieve the effect of reducing difficulty, shortening maintenance time, and reducing downtime

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

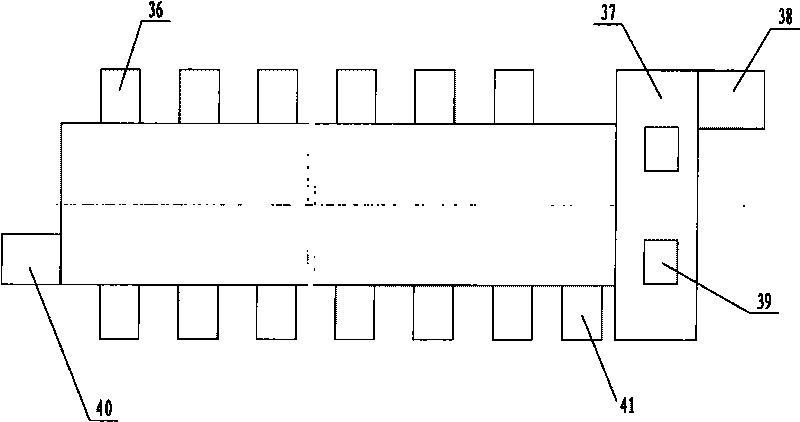

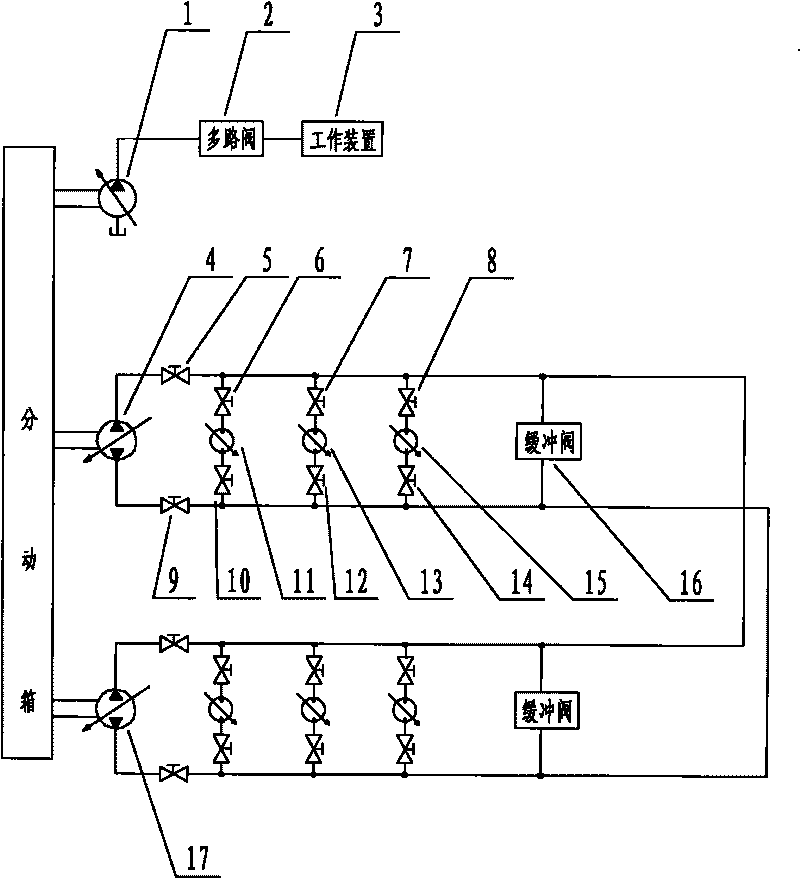

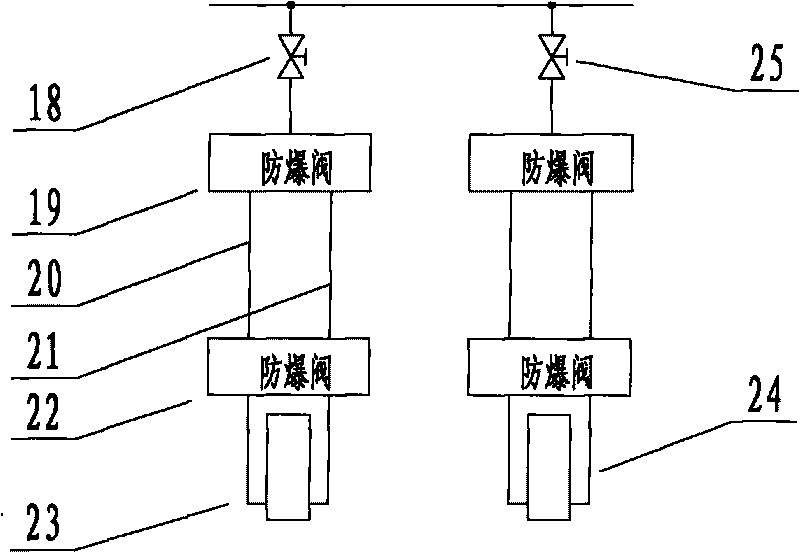

[0021] Embodiment 1: The hydraulic control system includes a hydraulic system pump, a travel motor fault isolation device 41, a hydraulic system pipeline explosion-proof device, a travel motor fault emergency treatment device, a beam 36, a power compartment 37, a rear cab 38, an engine 39 and a front Cab 40, there are 16 beams on both sides of the vehicle, each beam is connected with a motor failure emergency treatment device and an explosion-proof pipe device, there is a cab at the front and rear, and there is a power compartment at the rear. The engine is symmetrically placed inside, the engine is connected with the hydraulic pump, the travel motor is connected with the closed pump through a ball valve, and the hydraulic system pump and the travel motor fault isolation device 41 are connected to one side of the main beam and are positioned at the rear of the engine 39.

[0022] The hydraulic system pump and travel motor fault isolation device include an open pump, a closed pu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com