Draught fan fault monitoring system

A fault monitoring and fan technology, applied in signal transmission systems, mechanical equipment, machines/engines, etc., can solve problems such as complex wiring and difficult troubleshooting of fault points, avoid inconvenience, realize mobile monitoring, system improvement and convenience Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

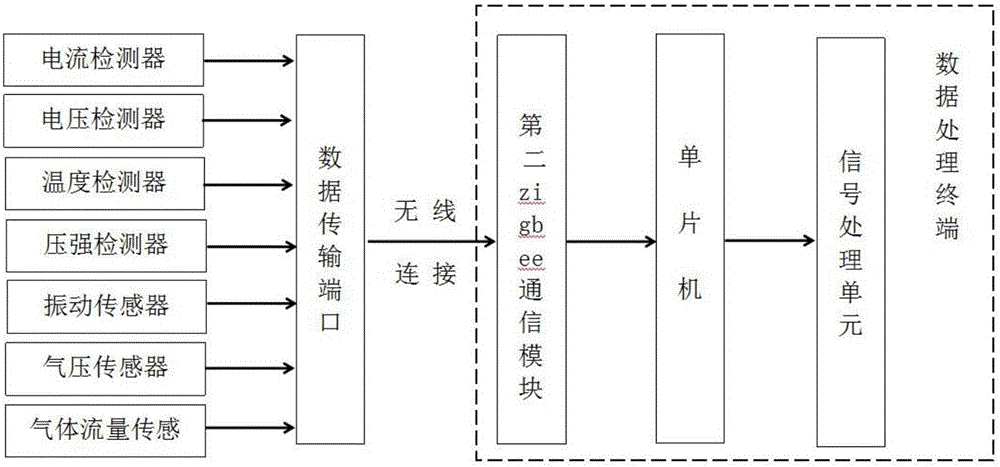

[0014] In order to describe the technical solution provided by the present invention in more detail, further description will be made here in conjunction with the accompanying drawings.

[0015] refer to figure 1 As shown, the fan fault monitoring system provided by this application includes a fan body installed on the fan work site, a sensor assembly installed on the fan body for collecting various states of the fan when it is working, and a sensor assembly installed on the fan body for A data transmission port for transmitting data and a data processing terminal for processing and displaying data information collected by sensor components; the sensor components include current detectors, voltage detectors, temperature detectors, pressure detectors, vibration sensors, air pressure sensors and a gas flow sensor; the data signal collected by the sensor assembly is uploaded to the data processing terminal in a wireless manner through the WI-FI networking port included in the dat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com