Bucket wheel machine rotation angle measuring and coal flow balancing method based on image processing

A technology of rotation angle and image processing, applied in image data processing, measuring devices, image enhancement, etc., can solve problems such as slow operation, low reliability, unreliable correction, etc., achieve strong reliability, improve feasibility, and solve problems correcting difficult effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

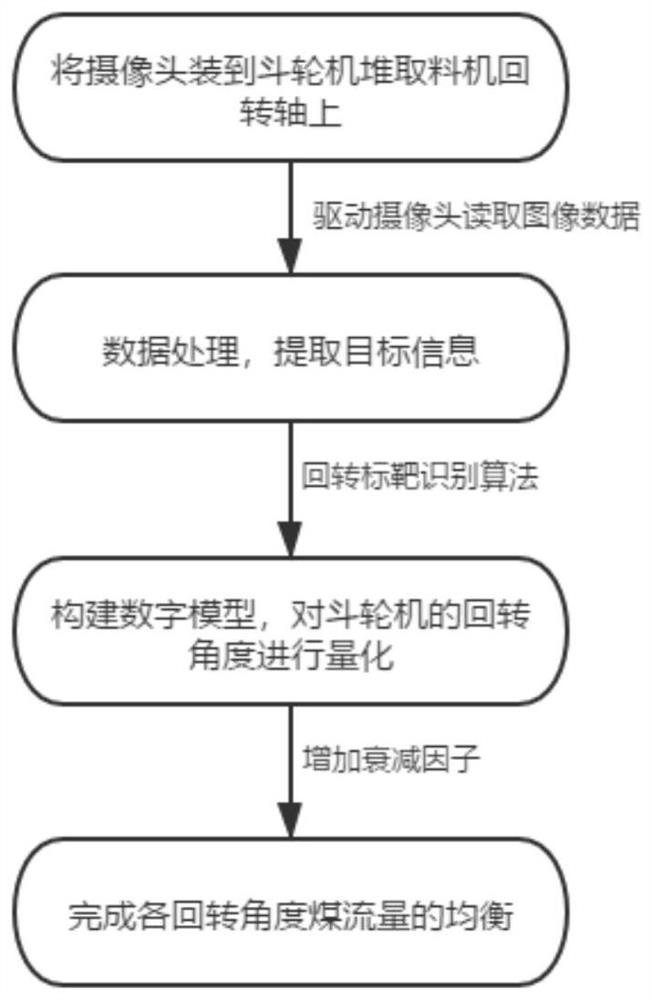

[0033] refer to Figure 1 to Figure 4, which is the first embodiment of the present invention, provides a bucket wheel machine rotation angle measurement and coal flow equalization method based on image processing, specifically including:

[0034] S1: Based on the digital image processing strategy of the FPGA platform, the camera is installed on the rotary shaft of the bucket wheel stacker and reclaimer.

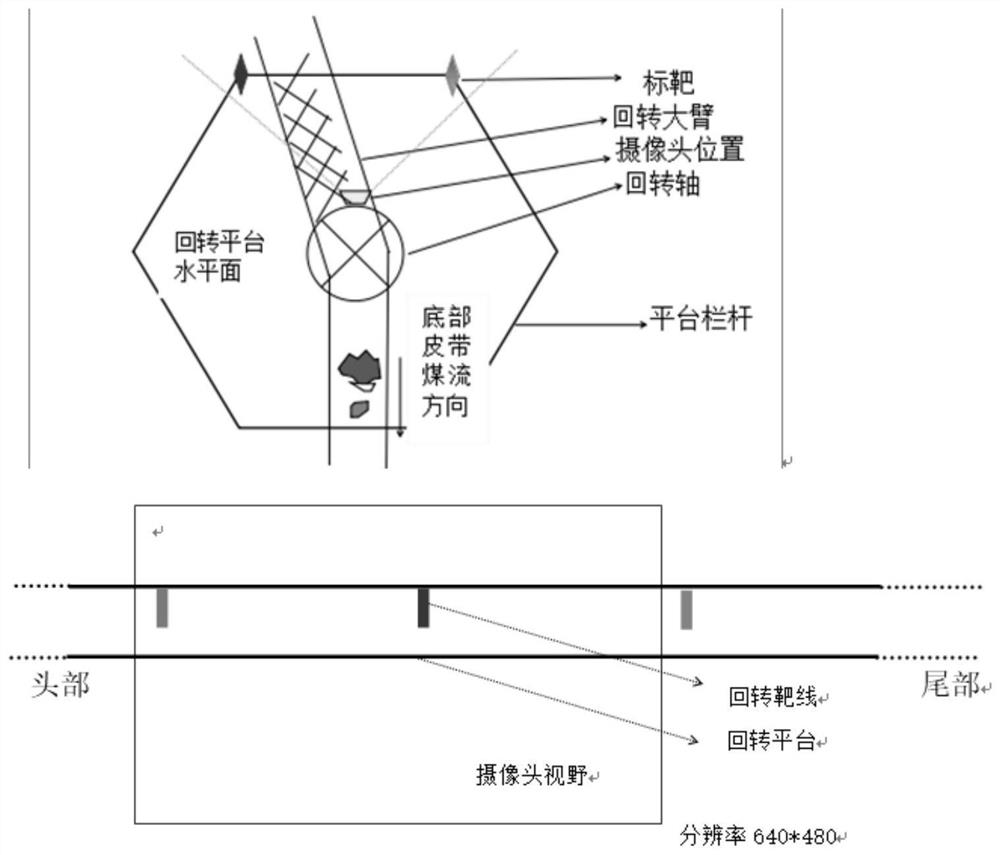

[0035] S2: Use the FPGA platform as the main control hardware platform to drive the camera to read the image data and perform data processing on it to extract the target information.

[0036] S3: Use the rotary target recognition algorithm to construct a digital model to quantify the rotary angle of the bucket wheel machine.

[0037] S4: Send the attenuation factor to the rotary motor control PLC through the radio frequency module to complete the balance of coal flow at each rotary angle.

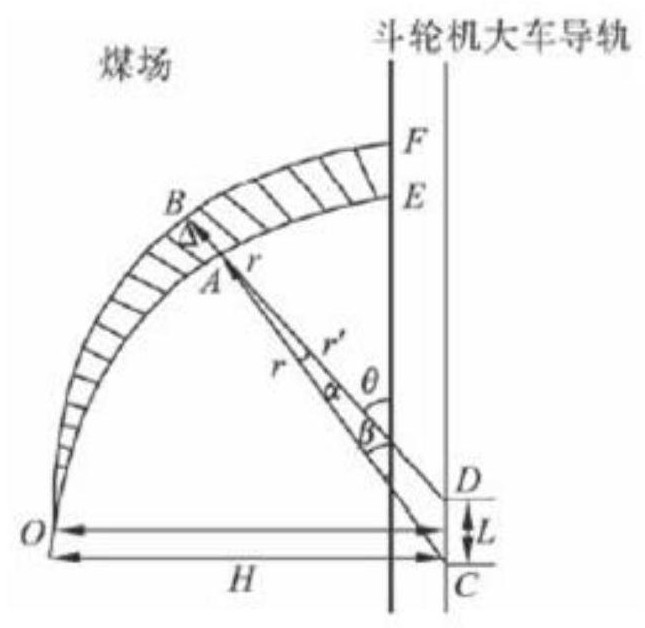

[0038] refer to figure 2 , using the digital model to obtain the coal flow rate o...

Embodiment 2

[0072] refer to Figure 5 ~ Figure 7 , which is the second embodiment of the present invention. This embodiment is different from the first embodiment in that it provides a comparison of power consumption and economic comparison of bucket wheel machine rotation angle measurement and coal flow equalization method based on image processing. tests, including:

[0073] refer to Figure 5 , the board model is EP4CE6F17C8, 256-pin FBGA package According to ALTERA official data, CYCLONE IV reduces power consumption by 25% compared to CYCLONE III.

[0074] refer to Image 6 , the image filtering used in this embodiment is the simplest mean filtering. Due to environmental factors and the noise characteristics of the camera itself, an image filtering algorithm is introduced. The mean filtering is a typical linear filtering. A template is introduced, which includes the current pixel, that is, the surrounding The 8 adjacent pixels constitute a pixel nine-square grid, which is a filter ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com