Horizontal two-degree-of-freedom vibration isolating mechanism

A vibration isolation, horizontal technology, applied in the direction of non-rotational vibration suppression, etc., can solve the problems of large volume of air spring piston, negative effect of vertical stiffness, limited volume, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

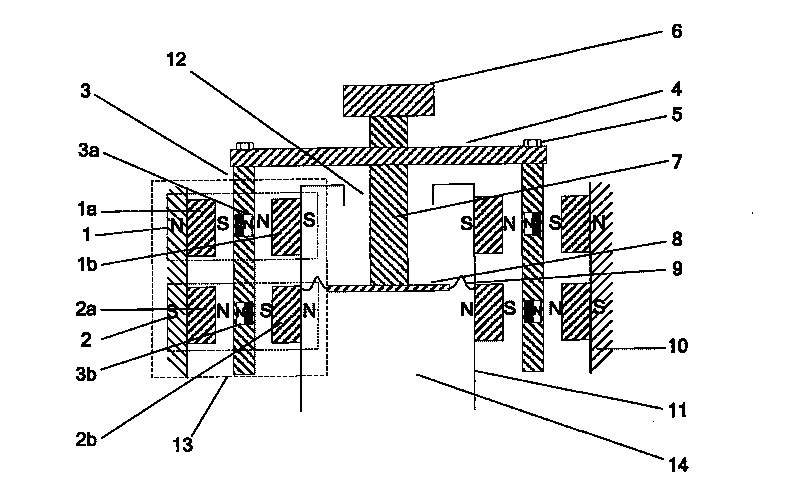

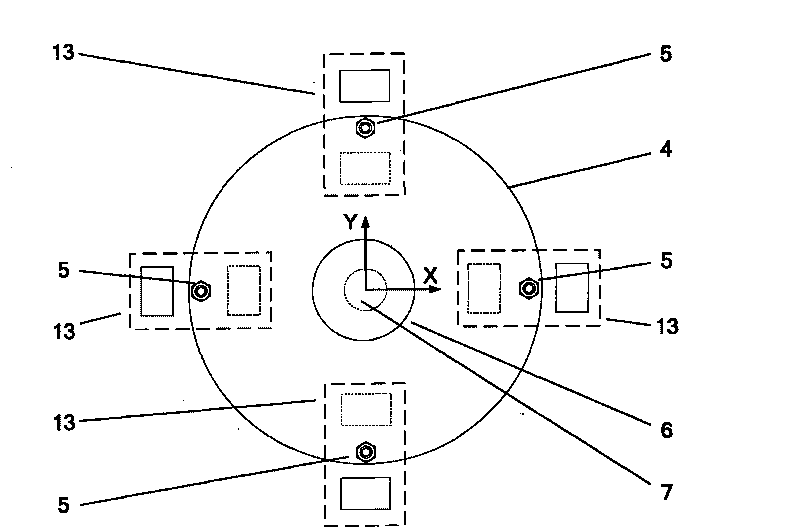

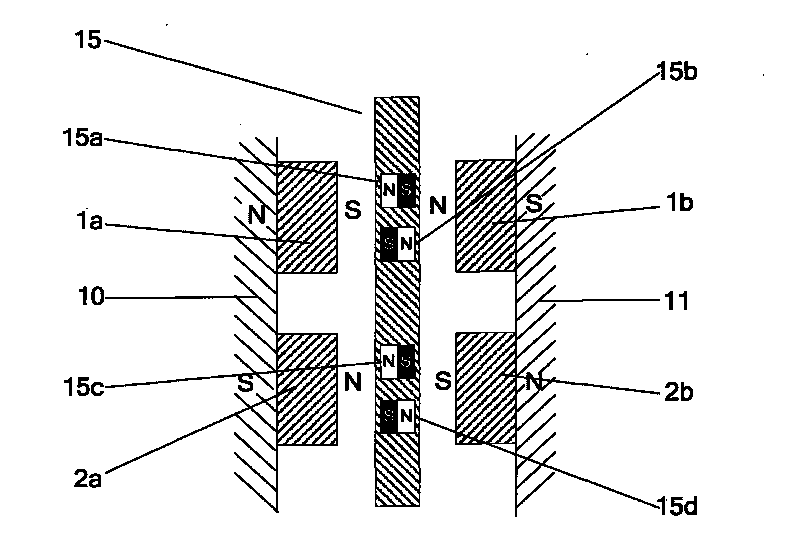

[0014] figure 1 Shown is a schematic structural view of the first embodiment of the zero-stiffness mechanism for horizontal two-degree-of-freedom vibration isolation of the present invention. Such as figure 1 As shown in , 1 is a pair of permanent magnets, and a pair of permanent magnets 1a and 1b of the same type are symmetrically arranged around the suspension rod 3 . The permanent magnet 1a is installed on the outer wall 10 of the vertical support cavity, the permanent magnet 1b is installed on the inner wall 11 of the vertical support cavity, and the S pole of the permanent magnet 1a is opposite to the N pole of the permanent magnet 1b. 2 is another pair of permanent magnets, and a pair of permanent magnets 2a, 2b of the same type as permanent magnets 1a, 1b are also arranged symmetrically around the suspension rod 3. The permanent magnet 2a is adjacent to the permanent magnet 1a and is installed on the outer wall 10 of the vertical support cavity. The permanent magnet 2...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com