Method for detecting peculiar smell caused by acetic acid and propionic acid in tobacco sheets

A technology for tobacco sheet and acetic acid, which is applied in the field of detection of food odor, can solve the problem of no tobacco sheet acetic acid and propionic acid detection methods, etc., and achieves the effects of simple operation, fast analysis process, and simple test operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment 1

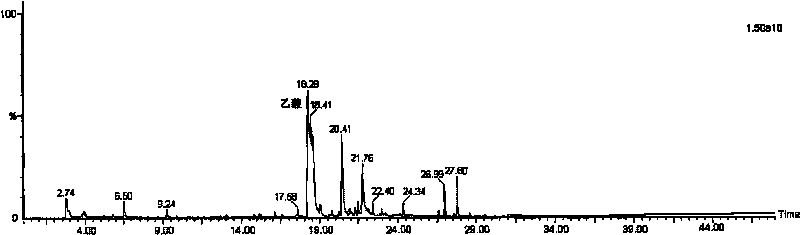

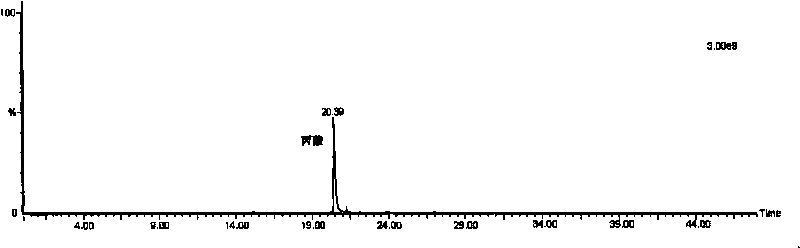

[0029] Test the normal flake samples without obvious peculiar smell and some flake samples with peculiar smell. Weigh 1 g of normal flakes and place them in a headspace vial and put them into O·I·Analytical 4552 liquid / solid autosampler. Set the temperature of XFERLine and US Valve to 150°C and 120°C respectively. Preheat the sheet at 40°C for 15 minutes, then blow it to the trap for 30 minutes, dry blow for 6 minutes to remove the water blown into the trap, and then heat the trap to 250°C for 2 minutes for desorption. After desorption, the trap was baked at 260°C for 10 minutes to remove residual substances in the trap. The desorbed substances enter the PerkinElmer Clarus 600 gas chromatograph along with He gas. After temperature programming was carried out according to step (5) in the summary of the invention, the sample separated by chromatography was analyzed by PerkinElmer Clarus 600T mass spectrometer. After completion, repeat the above process for the analysis of the...

specific Embodiment 2

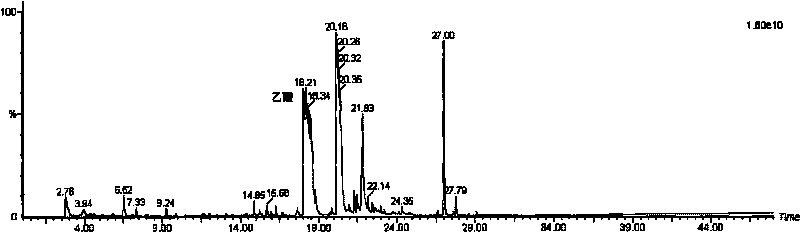

[0030] A certain substrate and the thin slice samples produced by using the substrate are tested. Weigh 1 g of the substrate and place it in a headspace vial and put it into an O·I·Analytical 4552 liquid / solid autosampler. Set the temperature of XFER Line and US Valve to 150°C and 120°C respectively. Preheat the sheet at 40°C for 15 minutes, then blow it to the trap for 30 minutes, dry blow for 6 minutes to remove the water blown into the trap, and then heat the trap to 250°C for 2 minutes for desorption. After desorption, the trap was baked at 260°C for 10 minutes to remove residual substances in the trap. The desorbed substances enter the PerkinElmer Clarus 600 gas chromatograph along with He gas. After temperature programming was carried out according to step (5) in the summary of the invention, the sample separated by chromatography was analyzed by PerkinElmer Clarus 600T mass spectrometer. After completion, repeat the above process for the analysis of the flake samples...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com