Lens eccentricity fine adjustment mechanism in projection lithography objective

A fine-tuning mechanism and projection light technology, which is applied in microlithography exposure equipment, optics, optical components, etc., can solve problems such as deviation tolerances, achieve the effects of preventing stress deformation and plane torsion, low cost, and improving imaging quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

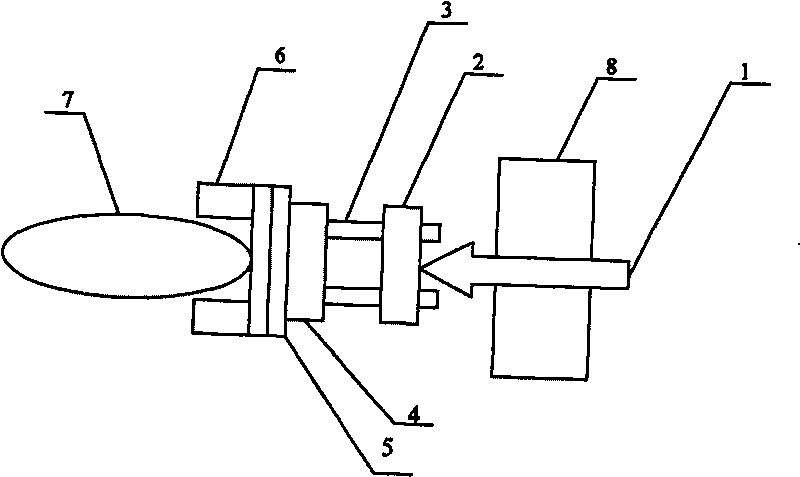

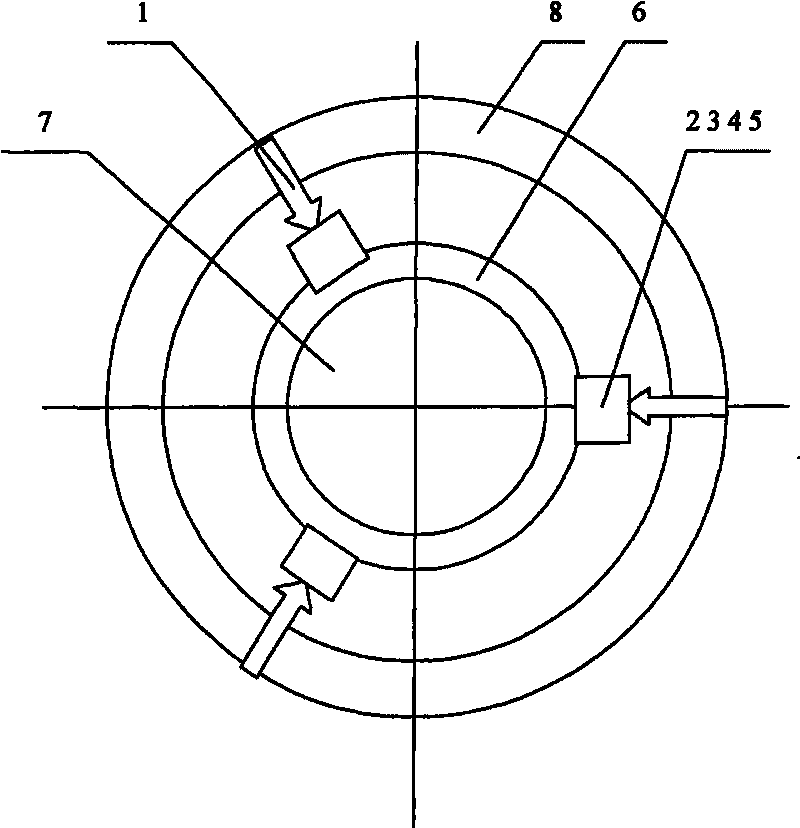

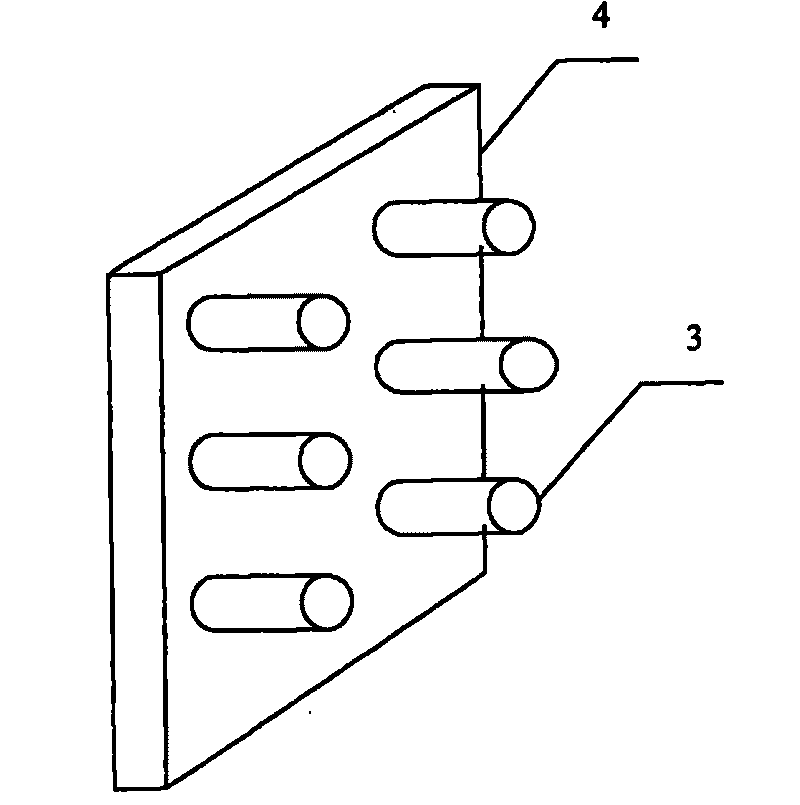

[0011] Such as figure 1 , 5 As shown, the lens eccentric fine-tuning mechanism of the present invention is installed on the lens frame 6 and the lens barrel 8, the lens frame 6 is located in the lens barrel 8, and there is a certain gap between the lens barrel 8 to ensure the displacement adjustment of the lens. The lens eccentric fine-tuning mechanism includes a fine-tuning head 1, a slider 2, a guide column 3, a guide column base 4, and an elastic pad 5. In the embodiment of the present invention, the elastic pad may be an elastic material such as elastic silicone. The fine tuning head 1 is installed in the lens barrel 8 and is perpendicular to the optical axis of the objective lens. The elastic pad 5 is installed on the side of the lens frame 6 . The contact surface between the guide post base 4 and the lens frame 6 is the elastic pad 5 . Such as image 3 , 4 As shown, the slider 2 is embedded in the guide column 3 on the guide column base 4. In order to ensure the line...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com