Stroke-correction transverse transmission mechanism of stretch yarn machine

A technology of transmission mechanism and elastic wire machine, which is applied to electromechanical devices, electric components, control mechanical energy, etc., can solve the problems of poor traverse transmission accuracy, fuzzy control, and difficult parts processing, and achieve accurate zero return position and overcome inertia. The effect of high error and transmission accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0008] Below the present invention will be further described in conjunction with the embodiment in the accompanying drawing:

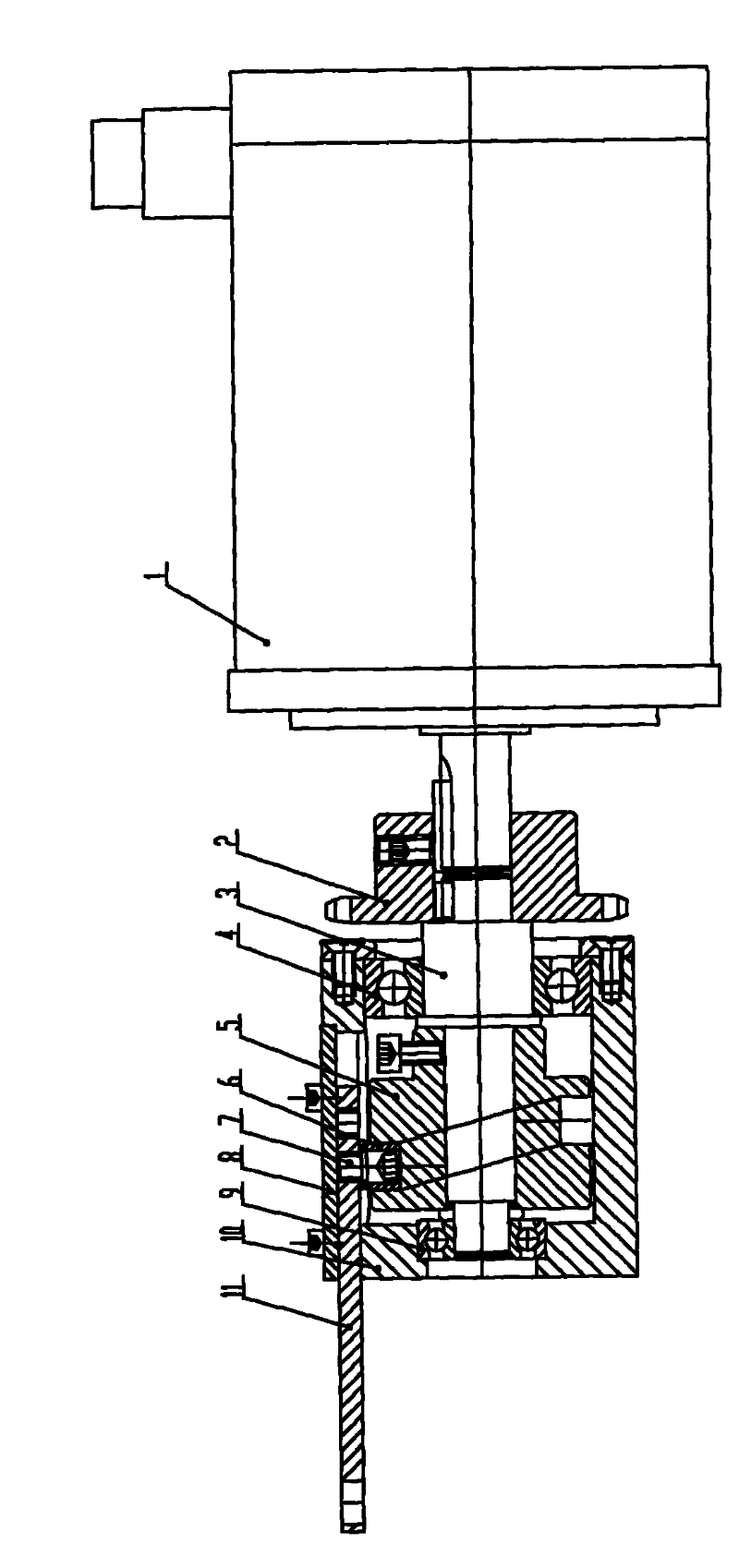

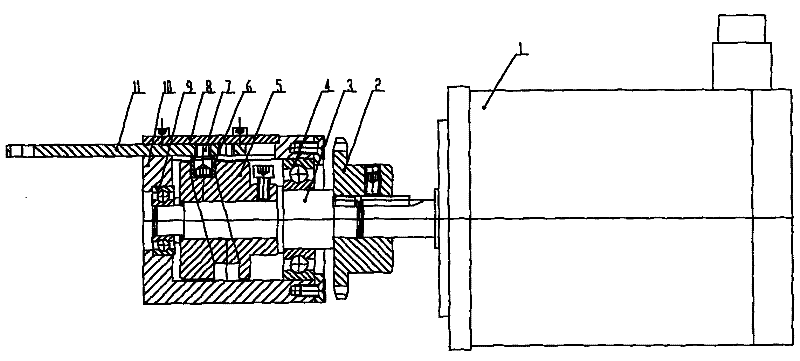

[0009] Such as figure 1 Shown: including stepping motor 1, sprocket 2, camshaft 3, first auxiliary bearing 4, cam 5, sliding sleeve 6, slider 7, pressure plate 8, second auxiliary bearing 9, cam sleeve 10 and sliding rod 11 Wait.

[0010] In the present invention, the stepper motor 1 is connected and fixed with the sprocket 2, the camshaft 3 and the cam 5, the sliding sleeve 6, the slider 7 and the sliding rod 11 are fixedly connected, and the camshaft 3 passes through the first auxiliary bearing 4 and the second auxiliary bearing 9. Connected with the cam sleeve 10, the sliding sleeve 6 is rollingly connected in the groove of the cam 5, and the sliding rod 11 is limited by the groove of the pressure plate 8 and the cam sleeve 10.

[0011] Working process of the present invention:

[0012] In the present invention, the stepping motor 1 drives the ca...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com