Method for manufacturing shadow changing recombined decorative wood by using natural wood

A technology for recombining decorative wood and wood, which is applied in the field of wood processing, can solve problems such as design and change that do not involve gloss attributes, achieve great economic and social benefits, and avoid over-development

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0018] The method that natural wood of the present invention makes light and shadow changing recombination decorative wood (teak Afrormosia) at least comprises the following steps:

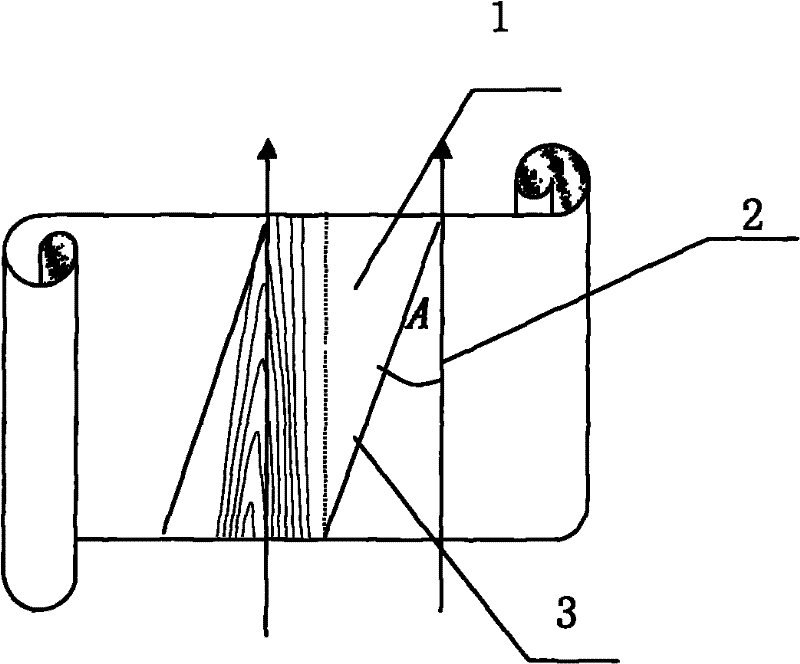

[0019] 1) Production of veneer: select cheap and oily kauri species, rotary cut 0.6mm thick oblique cut into 2580×690mm format veneer 1, see figure 1 The veneer 1 is dyed into a color close to the natural tree species Afrormosia after being bleached, and then dried to a moisture content of 6-20%, and the knots, cracks and color defects in the veneer 1 are repaired. The produced veneer 1 has an oblique angle A between most of the wood fiber direction 2 and the long side 3 of the veneer, and the angle range of the oblique angle A is 0°<A<90°;

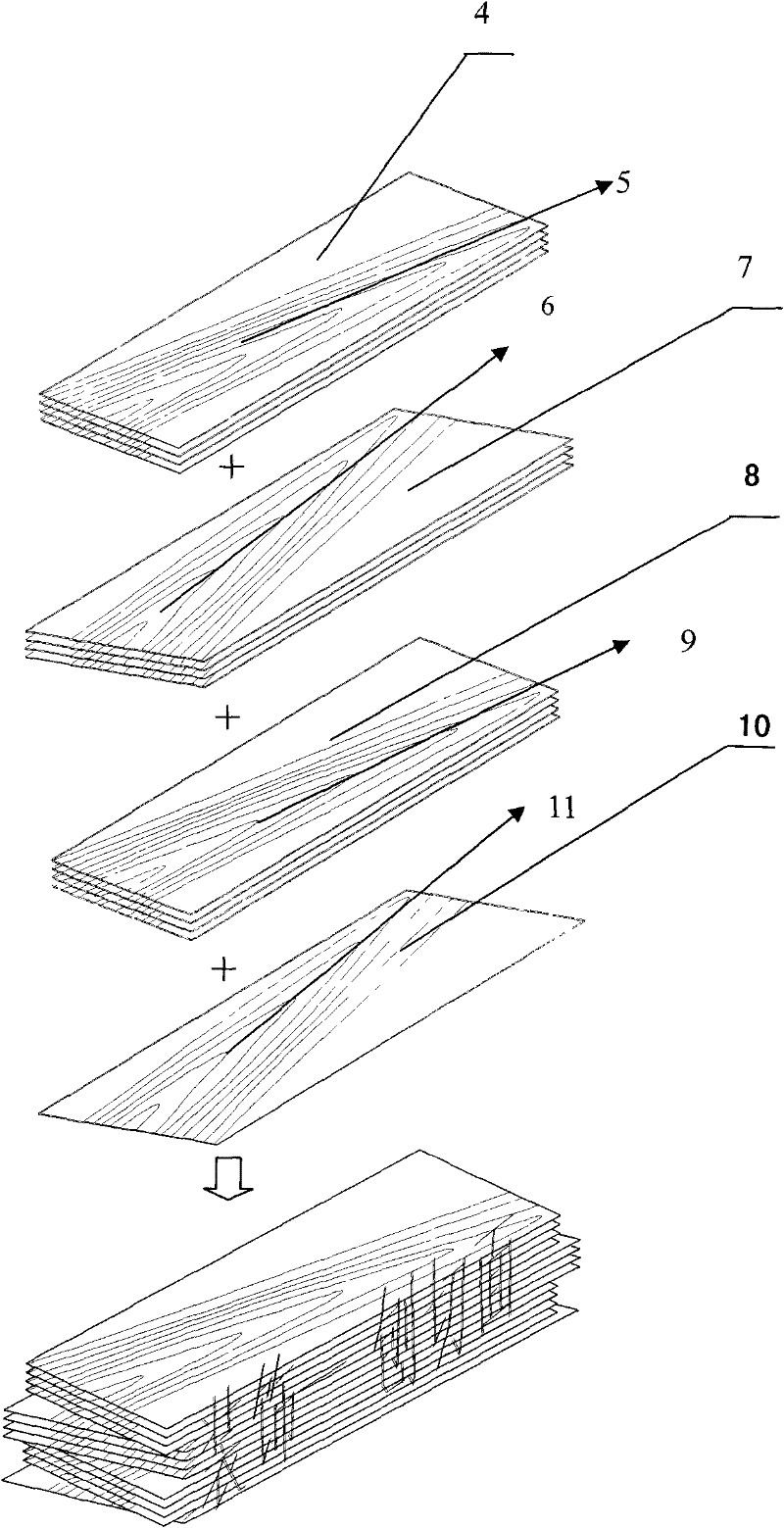

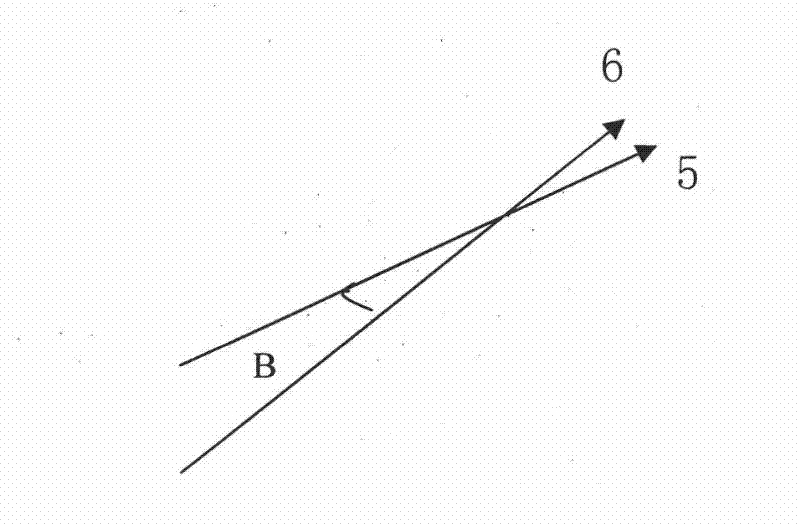

[0020] 2) The veneer 1 is pressed into the first wood frame: the veneer is first coated with glue, and the veneer after the glue is weaved into groups, and each veneer group is arranged crosswise according to the fiber direction, and then pressed with pressur...

Embodiment 2

[0026] The method for making light and shadow changing recombined decorative wood (ripple shadow wood) from natural wood, see Figure 4 .

[0027] Design and process the wave shadow wood mold with CNC machine tools. The upper and lower parts of the mold have wave structures to produce such as Figure 4 The corrugated shadow wood 12.

[0028] Choose cheap fast-growing poplar veneer with a thickness of 0.6mm and a format size of 2.54m×0.74m.

[0029] After bleaching and washing the veneer, put it into the solution added with softener to cook and soak for two hours. Dry until the moisture content is 8-25%, and repair the knots, cracks and color defects in the veneer.

[0030] Use water-based isocyanate adhesive, glue amount 120~200g / m 2 , put 1~15 sheets of veneer into the mold each time, place the length direction as shown in the figure, and press it in multiple layers at 15~50kgf / cm 2 A total of 300 to 900 veneers are pressed under pressure, and the pressure is kept at roo...

Embodiment 3

[0033] For the method of making light and shadow changing recombined decorative wood from natural wood, see Figure 5 . The recombined decorative wood described in the method is formed by gluing together the wooden blocks 15 and 16 with different wood fiber directions. In the special case of wooden block 15 and wooden block 16, the veneer is thick to a certain extent, the method at least includes the following steps:

[0034] 1) Saw the wooden block so that there is an oblique angle D between the wood fiber direction 13 of the wooden block 15 and the planing surface of the wooden block 15, and the angle range of the oblique angle D is 0°<D<90°; 2) planing The surface to be bonded; 3) Bonding: between adjacent blocks 15 and 16, the wood fiber direction 13 and the wood fiber direction 14 are cross arranged, and the wood fiber direction 13 and the wood fiber direction 14 are cross arranged to form the intersection angle F The angle is 0°<F<180°, then apply glue on the joint sur...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com