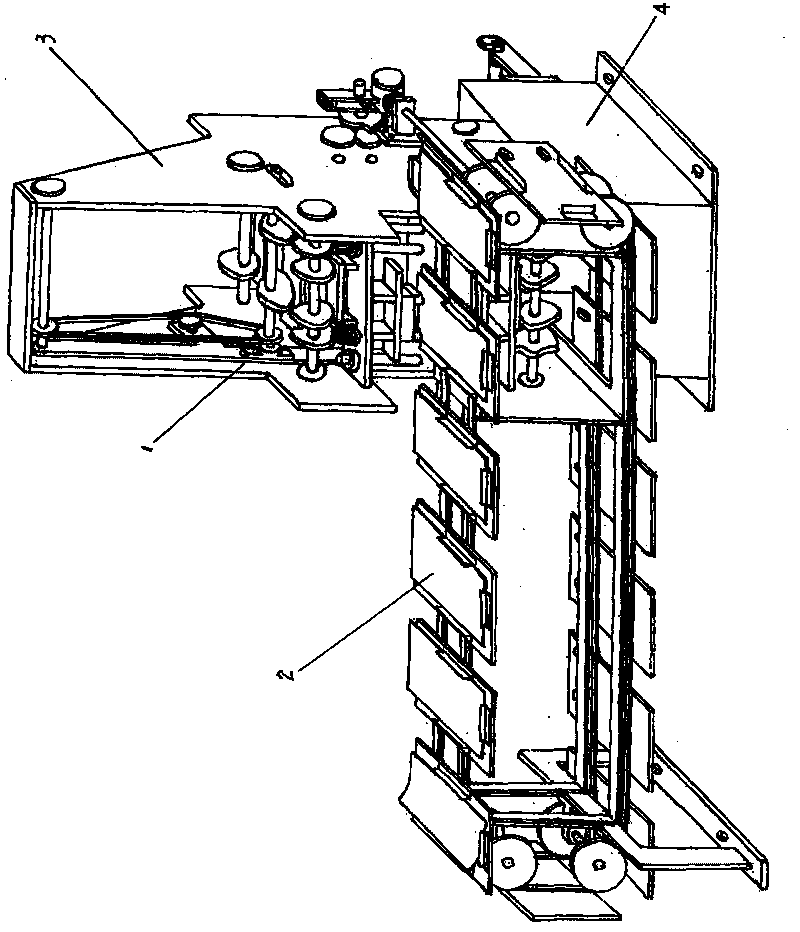

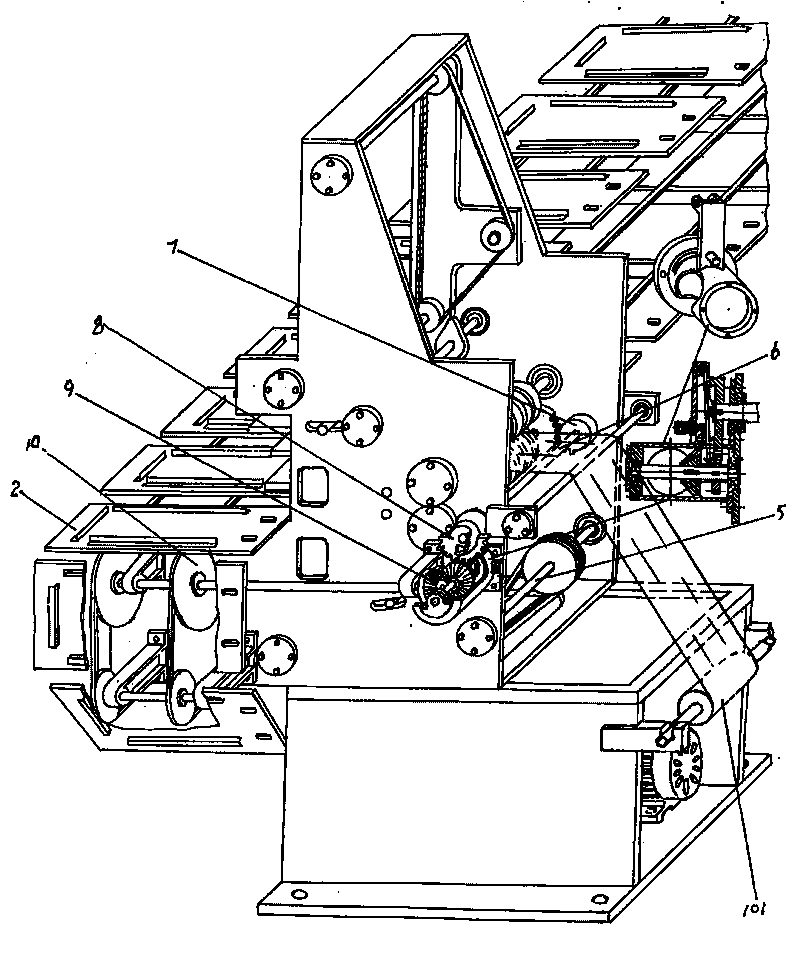

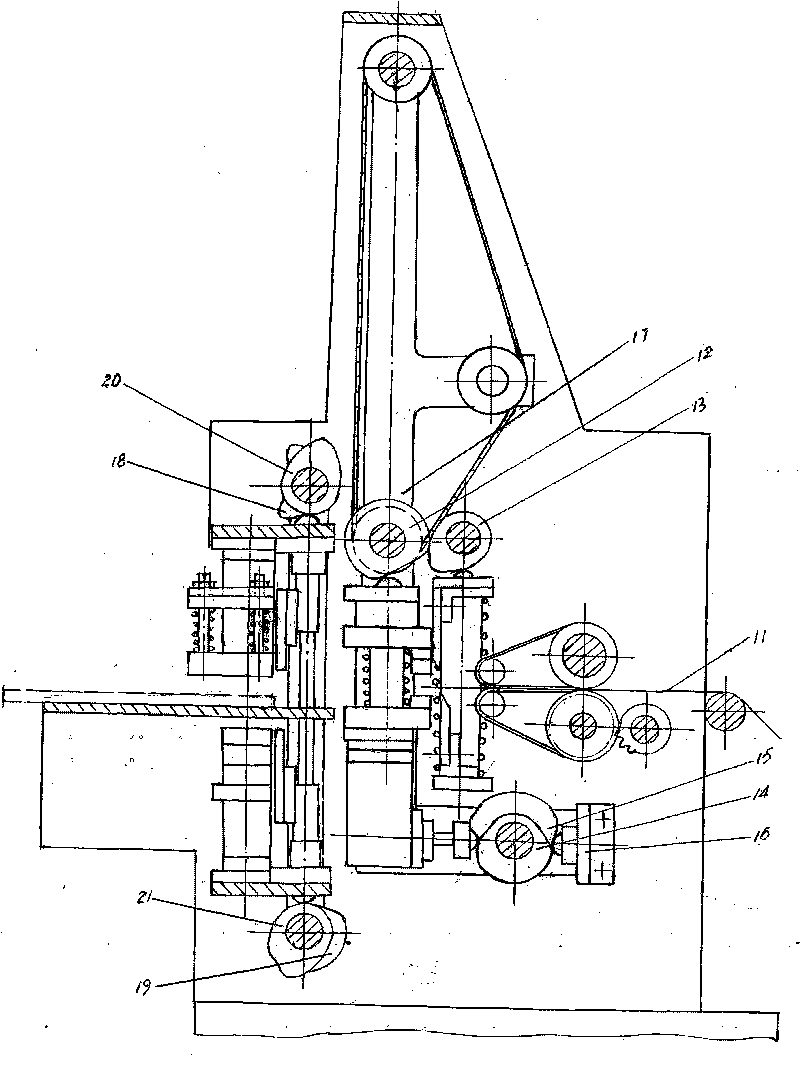

Automatic welding machine for plastic carry strips

A welding machine and plastic bag technology, which is applied in container manufacturing machinery, paper/cardboard containers, box production operations, etc., can solve the problem of suppressing the production and use of plastic bags

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0042] specific implementation plan

[0043] The present invention is further described below in conjunction with embodiment, and the production of a piece of equipment needs to carry out a series of operations such as design drawing, parts processing, complete machine assembly, adjustment trial and so on according to many factors such as working principle, stress situation and check and accept before can become an official product. Naturally, deficiencies will be found in use and still need to be improved. This welding machine is a purely mechanical automatic welding machine designed with cams, special-shaped gears and other parts on the basis of referring to a variety of similar welding machines to achieve the purpose of reducing manufacturing costs. Most of the content of this process will be omitted for the specific implementation plan here, and only the final debugging process of the product and some content that should be mastered when it is delivered to the user are de...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com