Multilayer microsome and anti-glare film thereof

A multi-level, microsome technology, applied in the direction of layered products, synthetic resin layered products, optics, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

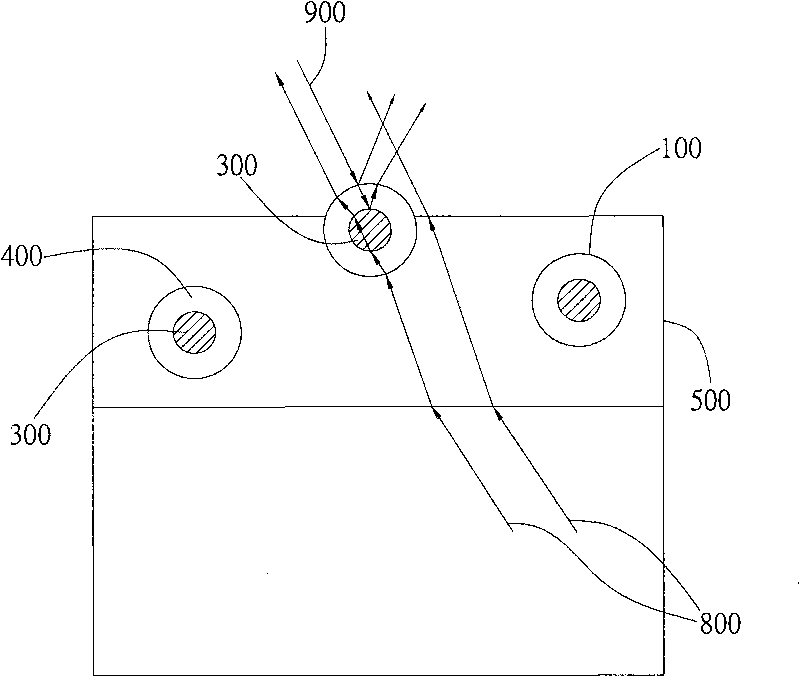

[0039] The invention provides a multi-layer microparticle used for an anti-glare film and an anti-glare film thereof, which have anti-glare properties and can prevent eyes from being hurt by glare in a high-brightness environment (such as under the sun). In a preferred embodiment, the antiglare film of the present invention can be attached to a liquid crystal display panel (LCD). However, in different embodiments, the anti-glare film of the present invention can also be attached to an organic light emitting diode display panel or a polymer organic light emitting diode (PLED) display panel. Specifically, the anti-glare film of the present invention can be applied to high-definition display devices such as various panel display screens, flat-screen TVs for home use, flat-panel monitors for personal computers and laptop computers, display screens for mobile phones and digital cameras, etc. superior.

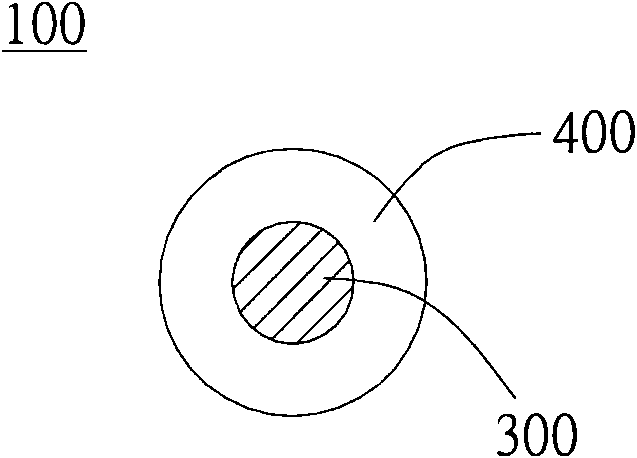

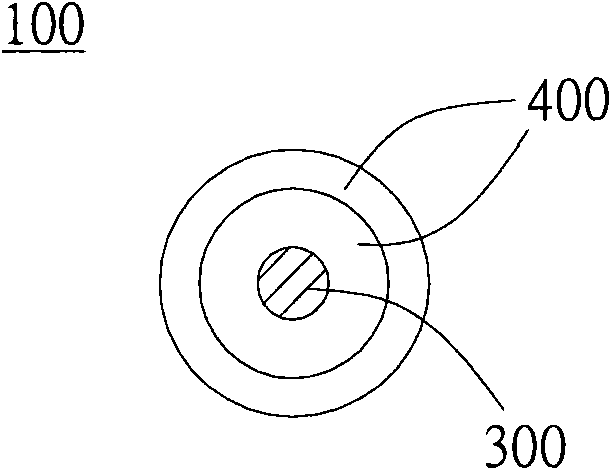

[0040] like Figure 1a As shown, the multilayered microsome 100 of the present...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| refractive index | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com