Brown pigment for ceramic ink jet printing and preparation method thereof

A technology of brown pigment and ceramic inkjet, which is applied in the field of brown pigment for ceramic inkjet printing and its preparation, can solve the problems of roughness, poor stability, simple production process, etc., and achieve high suspension and coloring power, good decorative effect, Vibrant hair color effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

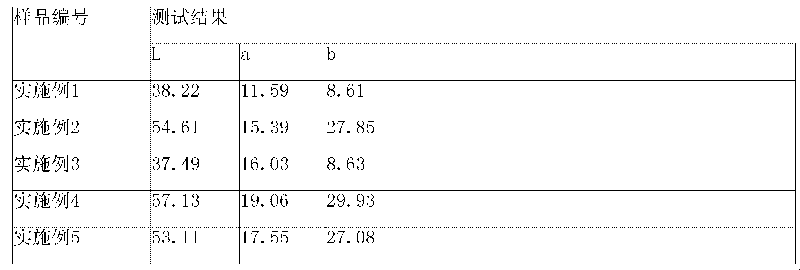

Examples

Embodiment 1

[0021] 1) Take CuO 5%, Cr 2 o 3 10%, Al 2 o 3 20%, SiO 2 5%, Fe 2 o 3 20%, ZnO 40%, using a stirring ball mill to refine the raw materials to sub-micron level, mix evenly, and burn at 1100°C for 4 hours to obtain crude pigments;

[0022] 2) Use a stirring ball mill to carry out ultra-fine processing on the crude pigment, until the powder is sub-micron;

[0023] 3) Use grading equipment to process ultra-fine powder and control its D 90 ≤1 靘, separate the ultra-fine powder to obtain the finished product.

Embodiment 2

[0025] 1) Take Cr 2 o 3 20%, Al 2 o 3 20%, Fe 2 o 3 40%, ZnO 20%, using a planetary mill to refine the raw materials to sub-micron level, mix them evenly, and burn them at 1300°C for 2.5 hours to get crude pigments;

[0026] 2) Use a planetary mill to carry out ultra-fine processing on the crude pigment, until the powder is sub-micron;

[0027] 3) Use grading equipment to process ultra-fine powder and control its D 90 ≤1 靘, separate the ultra-fine powder to obtain the finished product.

Embodiment 3

[0029] 1) Take CuO 10%, Cr 2 o 3 10%, Al 2 o 3 30%, SiO 2 5%, Fe 2 o 3 20%, ZnO 25%, use a stirring ball mill to refine the raw materials to sub-micron level, mix evenly, and burn at 1200°C for 3 hours to obtain crude pigments;

[0030] 2) Use a stirring ball mill to carry out ultra-fine processing on the crude pigment, until the powder is sub-micron;

[0031] 3) Use grading equipment to process ultra-fine powder and control its D 90 ≤1 靘, separate the ultra-fine powder to obtain the finished product.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com