Construction method for filling resin in convex blocking platform of plate-type ballastless-free rail

A slab-type ballastless track and resin-filled technology, which is applied in the field of rail transit, can solve the problems of low density, insufficient filling, and low strength, and achieve the effects of good adhesion, convenient operation, and simple construction methods

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

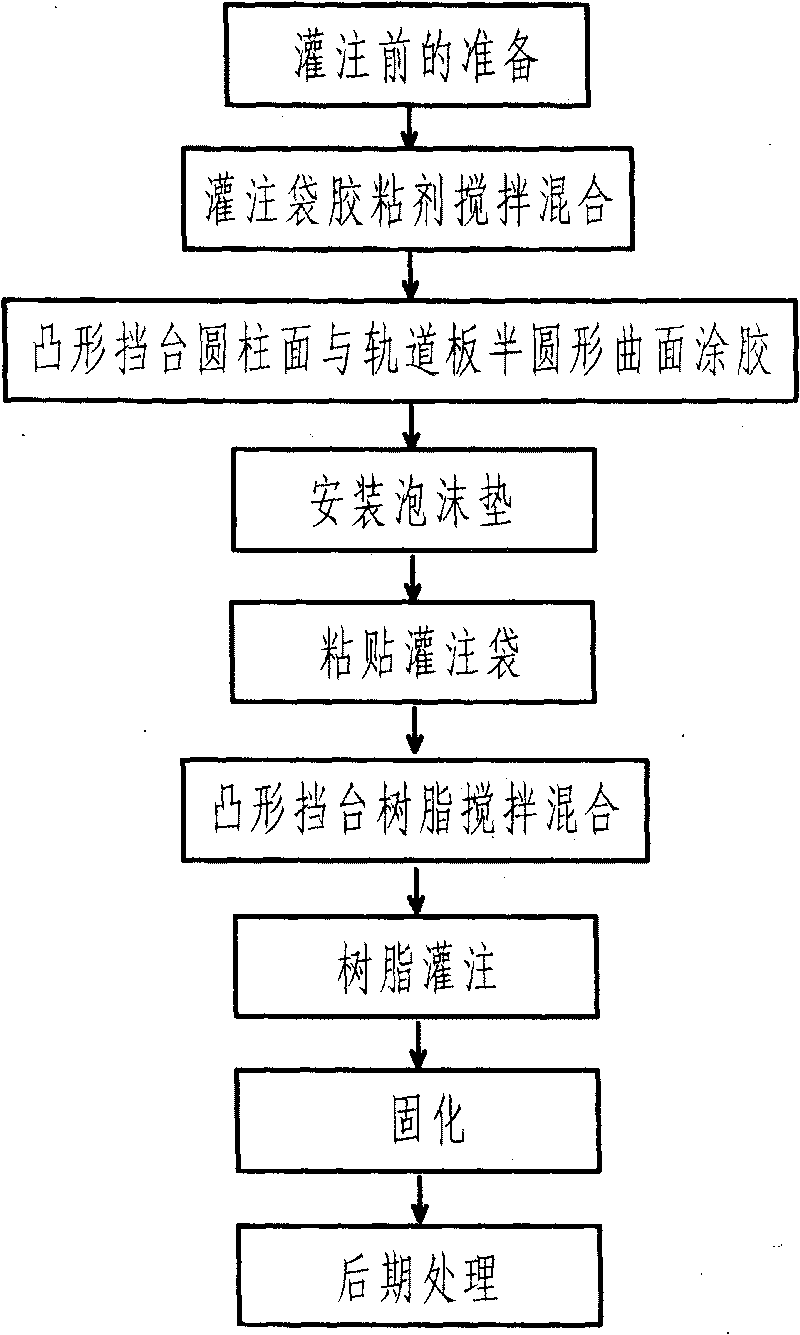

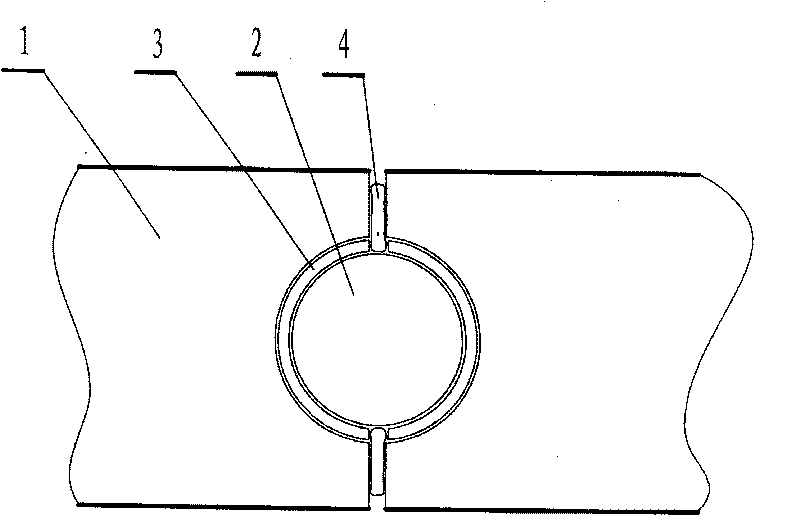

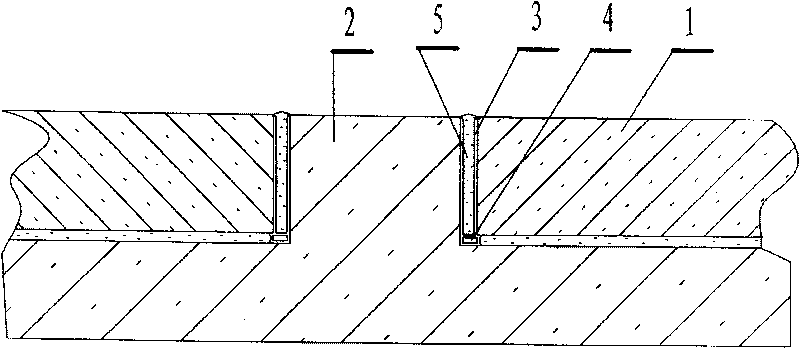

[0025] see Figure 1 to Figure 4 , the construction method of filling the resin on the convex block of the plate type ballastless track is to paste the perfusion bag (3) with adhesive between the convex block (2) and the track plate (1), and then fill the perfusion bag with the filling resin (5). (3) Perform pouring to make good adhesion between the convex block (2) and the track plate (1). Its construction method is:

[0026] 1. Preparation before pouring: remove garbage, sand, mud and other sundries around the convex stand (2), and dry the water with a dry cloth.

[0027] 2. Stir and mix the perfusion bag adhesive: remove the cover of the perfusion bag adhesive A and B components used for bonding the convex block (2) and the track plate (1), and then stir and mix according to the usage amount, and mix for 3-5 minutes uniform. The adhesive is epoxy resin type, polyurethane resin type or epoxy vinyl resin type, preferably epoxy resin type, and the stirring and mixing equipm...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com