Bent connecting rod offset bent shaft mechanism and bent connecting rod offset bent shaft motor

A technology for bending connecting rods and crankshafts, which is applied in the field of crankshaft connecting rod transmission mechanism and its engine, and can solve problems such as cylinder excessive wear or knocking, loss of power, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

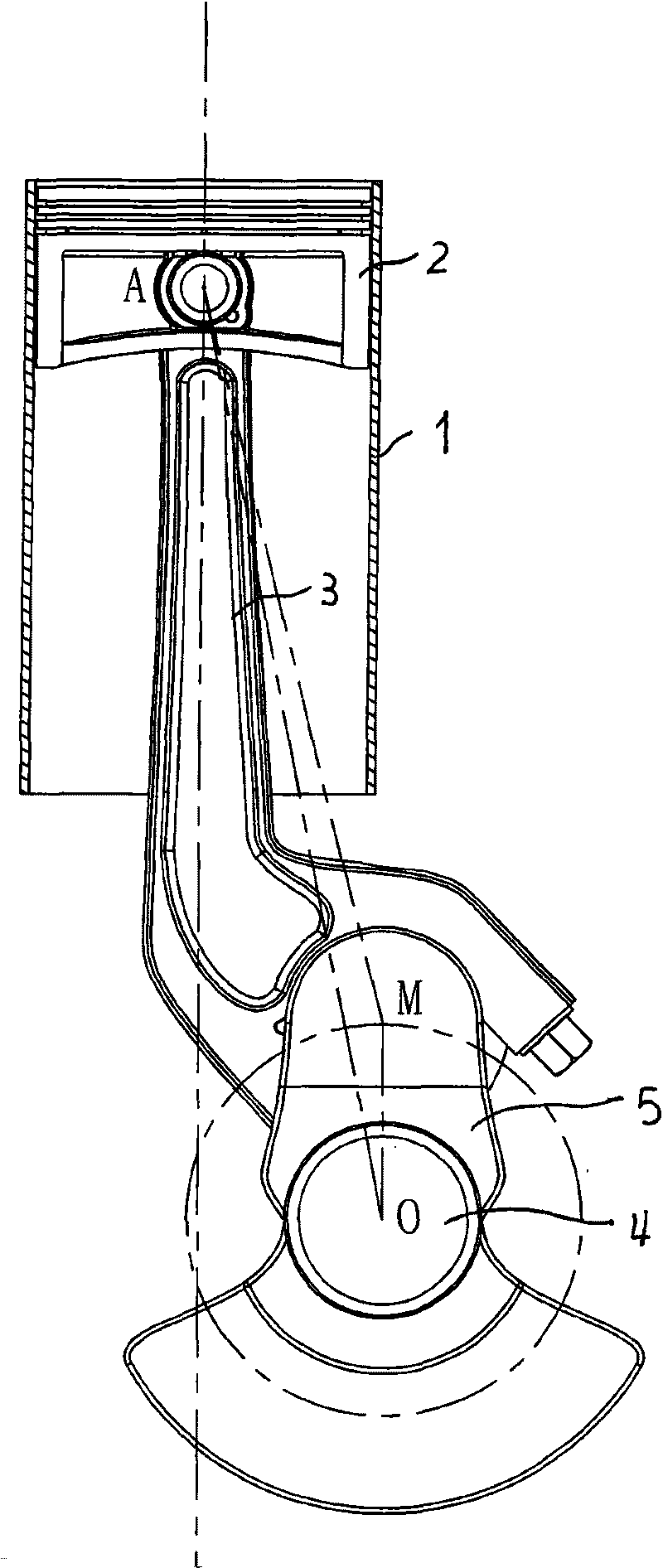

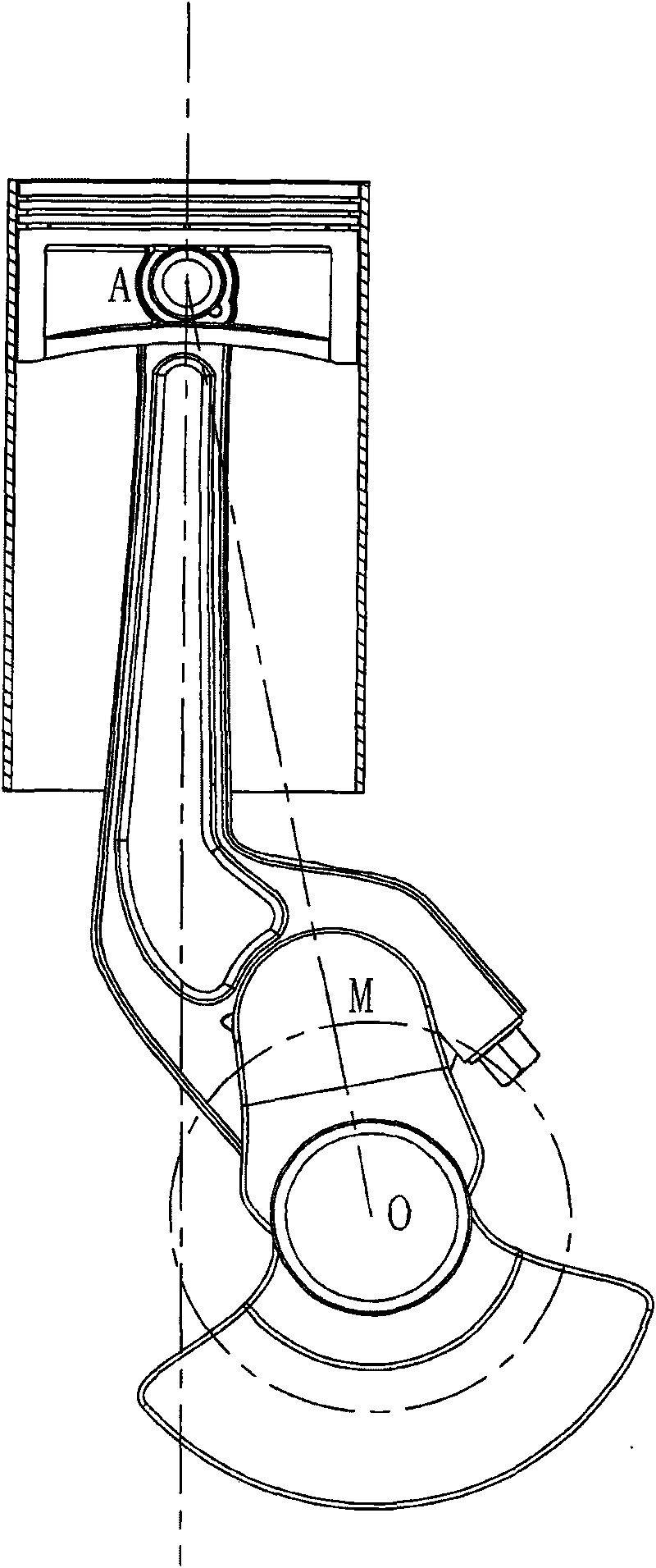

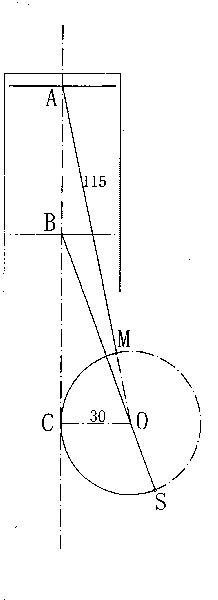

[0045] see figure 1 , this mechanism comprises cylinder 1, piston 2, connecting rod, crankshaft 4 and crank throw 5, intake cam 6 and intake rocker arm roller wheel 7, exhaust cam 8 and exhaust rocker arm roller wheel 9 (see Figure 18-2 ), the midpoint of the crankshaft circle deviates from the vertical centerline of the cylinder 1, and the offset is > 35% of the radius of the crankshaft. The connecting rod is a curved connecting rod 3, and the bending direction of the connecting rod in the mechanism is opposite to the offset direction of the crankshaft 4 (the bending direction of the connecting rod is according to figure 1 The arc direction of the middle connecting rod from the upper point to the lower point is counterclockwise). see Figure 22-3 , the bending shape of the connecting rod is that the connecting rod body bends to the outside of the connecting line between the two holes (piston shaft hole and crankshaft hole), and the bending direction of the connecting rod i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com