Method for fast measurement and judgment of central line of equipment like rotary kiln

An equipment center, rotary kiln technology, applied in lighting and heating equipment, measuring devices, rotary drum furnaces, etc. Long time and other problems, to achieve the effect of simple and easy measurement method, easy systematic management and low measurement cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

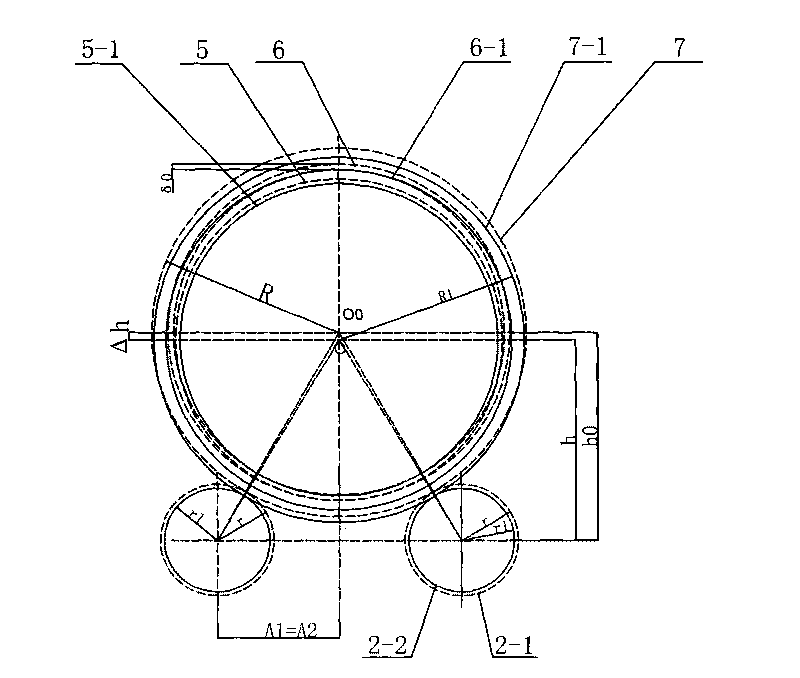

[0060] This embodiment specifically illustrates the method for quickly measuring and judging the centerline of a rotary kiln, including the following steps:

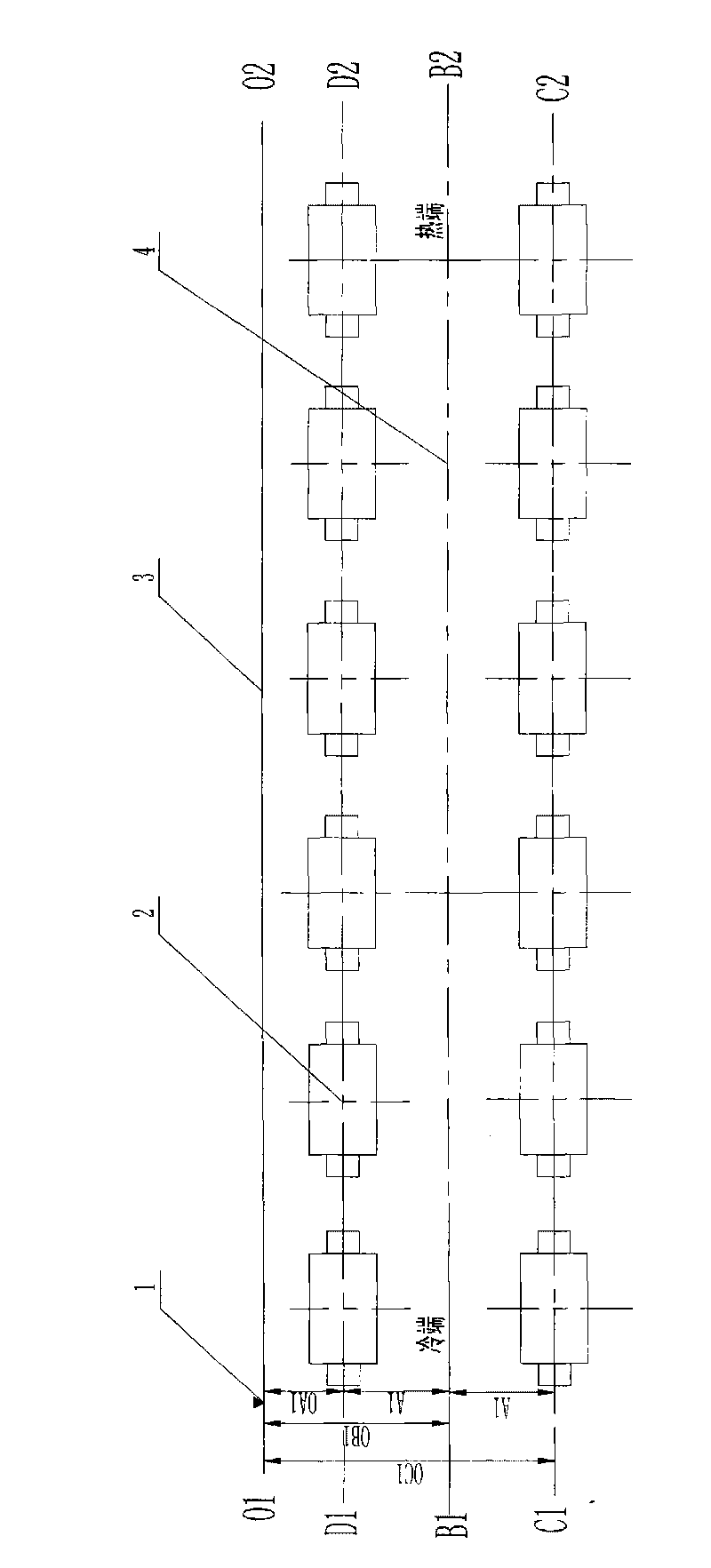

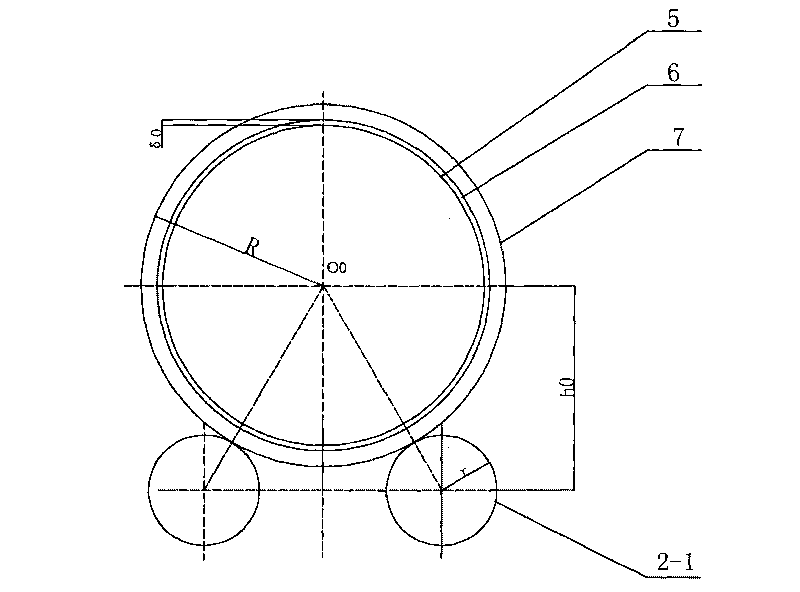

[0061] 1) The measurement of the actual horizontal projection distance A1 between the tire belt and the center line of the support roller, such as figure 1 shown.

[0062] First, set up a theodolite at the erection point 1 of the measuring instrument on the support seat of the supporting wheel set at the cold end of the rotary kiln, and establish a reference line 3 on the side of the rotary kiln with the center mark on the support seat of the supporting wheel 2 at both ends as the reference, It is required that the difference between the baseline 3 and the horizontal distance OB1 and OB2 between the original center marks at both ends when establishing the measurement point should be as small as possible.

[0063] Then, open the small end caps of the shaft heads of all supporting roller supports, find out the central mac...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com