Automobile constant speed engine given load detection method

A technology that specifies load and engine, applied in the direction of engine test, internal combustion engine test, machine/structural component test, etc. It can solve the problem of damage to the vehicle or engine, high sensitivity to load error and speed error, and bench test to simulate road test load. Comprehensive error and other problems, to achieve the effect of improving detection accuracy and improving detection efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

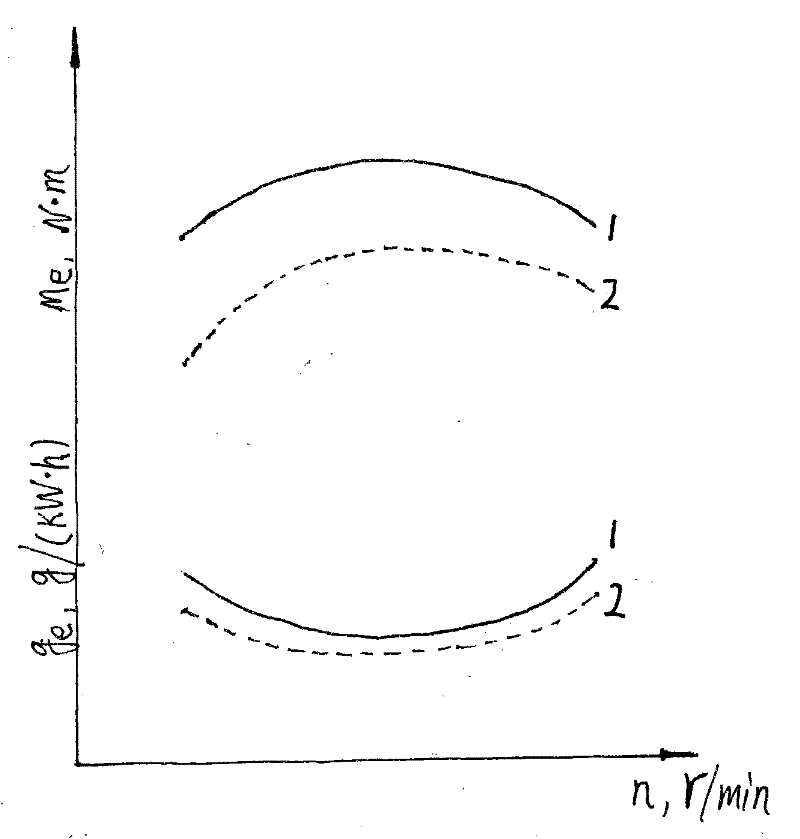

[0010] A domestic 1090 series truck constant-speed engine is loaded with a specified load to detect the fuel consumption rate and power performance to illustrate the specific implementation of the method: the engine rated power of this vehicle is 99kW / 2800r / min, and the maximum torque is 382Nm / 1700r / min , the direct transmission ratio is 1, the final reduction ratio is 6.33, the tire radius is 0.493m, and δ=0.75.

[0011] 1. Specified speed point V 1 is 55km / h, the engine accessory consumption torque is set at 0.07×382=26.74Nm directly at this speed point.

[0012] 2. Knowing the equivalent inertia of the chassis dynamometer and the vehicle’s neutral transmission system, the resistance of the vehicle’s neutral gear and the entire transmission system of the chassis dynamometer at the speed point of 55km / h is 760N, and the resistance power is 11.6kW. .

[0013] 3. Through the parameter calculation method, the ratio of the vehicle speed of the direct gear to the engine speed K=...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com