Comprehensive insulation and voltage resistance testing device of electric connector

A technology for comprehensive testing of electrical connectors, applied in the direction of testing dielectric strength, etc., can solve problems such as insufficiency of insulation and pressure withstand time, low degree of automation of test operations, unreasonable grouping of contact couples, etc., to achieve fixed energization The effect of short time, high test efficiency and accurate test time control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The present invention will be further described below in conjunction with accompanying drawing.

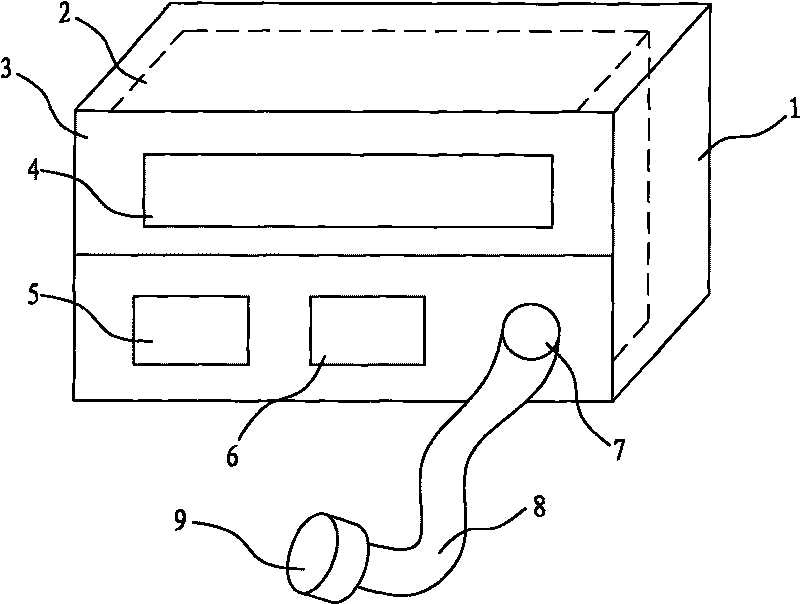

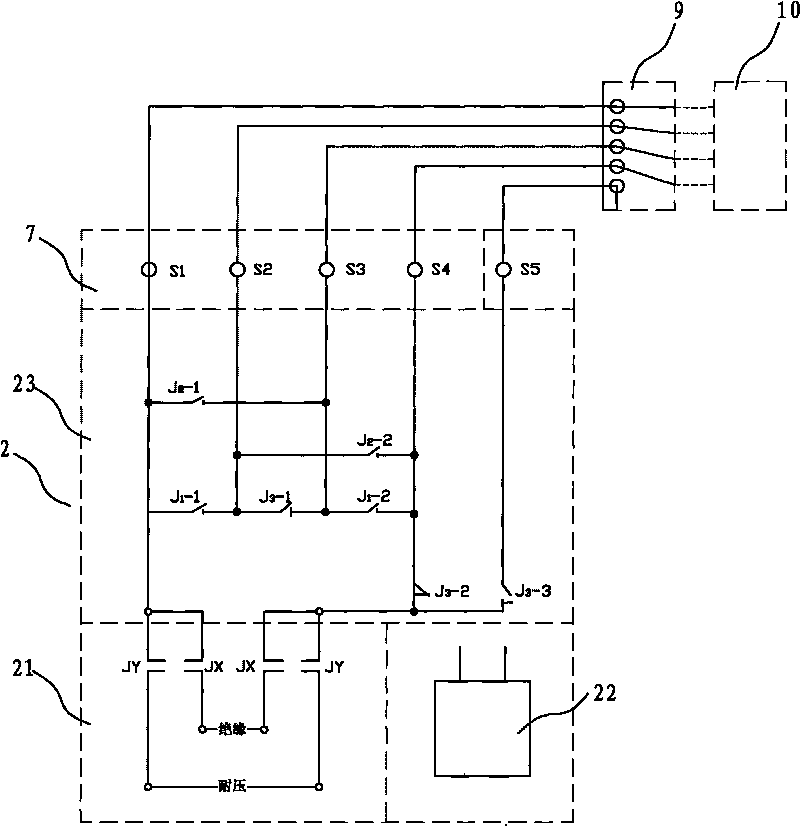

[0017] figure 1 , 2 The detection and control device shown mainly includes a test host 1, a test cable 8, and a conversion electrical connector 9. A control system 2 is arranged in the shell of the test host 1, a control panel 3 is arranged on the shell of the test host 1, and a control panel 3 is installed on the control panel 3. There is a display part 4, a starting device 5, an adjustment control device 6, and a common output interface 7. The common output interface 7 is connected to the conversion electrical connector 9 through the test cable 8, and the conversion electrical connector 9 is connected to the connector 10 of the point to be tested.

[0018] The control system 2 includes a test power supply 21, a sequence control circuit 22, a conversion execution circuit 23, and a common output interface 7. The test power supply 21 includes an insulation test power supply...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com