Automotive circuit detector

An automotive circuit and detector technology, applied in electronic circuit testing, instruments, measuring electricity and other directions, can solve the problems of long operation time, inconvenient operation, inability to operate, etc., and achieve small size, convenient use, safe and fast use. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The technology of the present invention will be further described below in conjunction with the accompanying drawings and embodiments.

[0015] The examples are not intended to limit the invention.

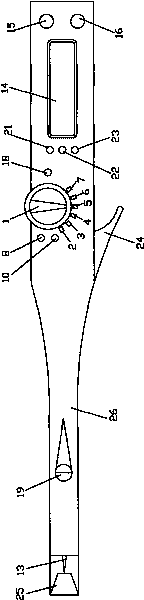

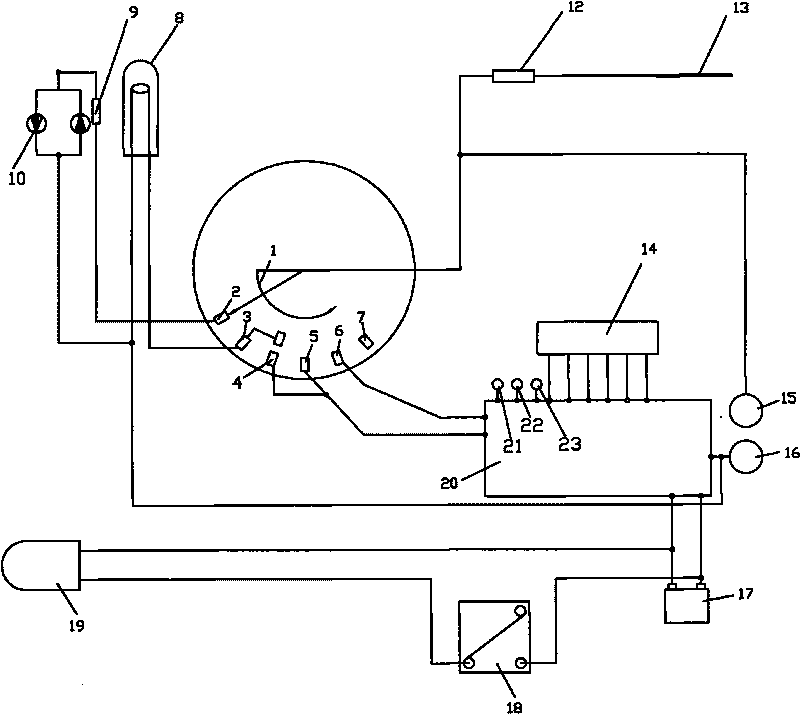

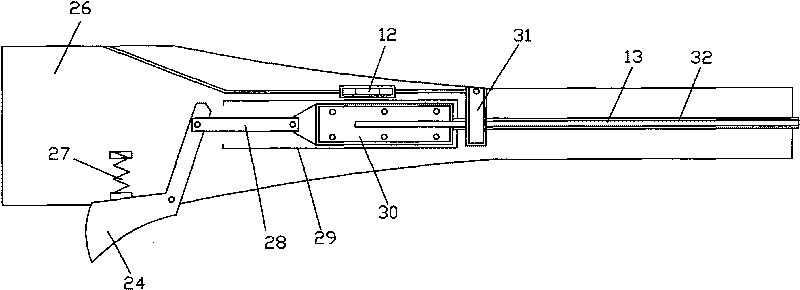

[0016] Such as figure 1 As shown, the automobile circuit tester of the present invention includes a housing 26, the housing is a small front and a large rear structure, a towing line hook 25 and a probe 13 are arranged on the top of the housing, and an illuminating lamp 19 is arranged at the front of the housing. , in the rear part of the housing from front to back, the sub-regions are arranged sequentially: trigger 24, electrodeless LED 10, test lamp 8, knob switch 1, LED gear 2 controlled by the knob switch, lamp test gear 3, lamp test and multimeter Gear 4, voltage gear 5, resistance gear 6, closed gear 7 multiple detection gears, lighting switch 18, multimeter use function keys: switching function key 21, backlight key 22, switching range key 23, display 14 and the tai...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com