Solar energy battery panel for automobile

A technology for solar panels and automobiles, applied in the field of solar cells, which can solve problems such as increased vehicle weight, inconvenient use, and failure of battery panels, and achieves the effects of simple structure, reduced thickness and weight, and easy preparation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

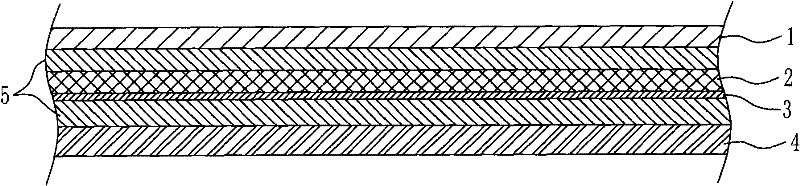

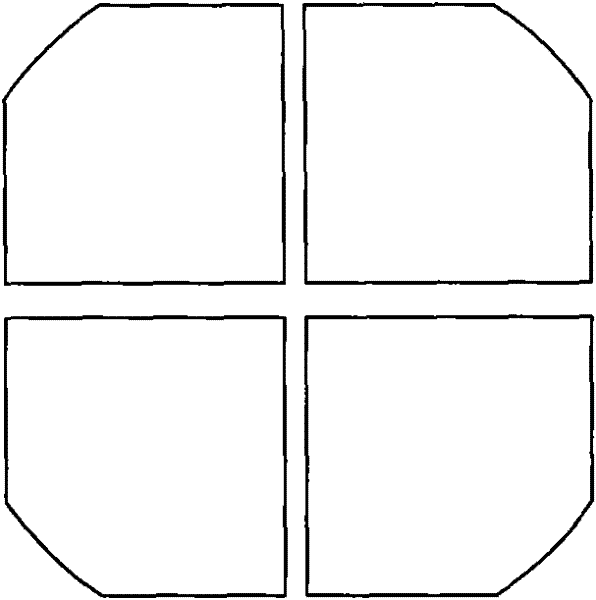

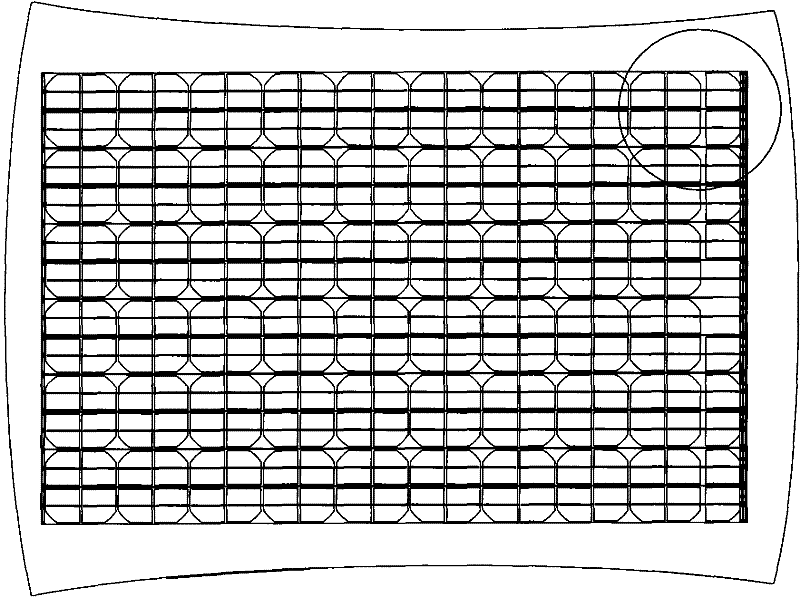

[0033] See attached Figure 1~4 As shown, a solar panel for automobiles includes a polyethylene terephthalate film 1, a crystalline silicon battery 2, a glass fiber 3, and a flexible epoxy resin board 4 from top to bottom. All are glued and fixed by adhesive 5. The adhesive is ethylene-vinyl acetate copolymer. The crystalline silicon cell is a quarter dicing of a crystalline silicon cell. The front and back sides of the flexible epoxy resin board are provided with contacts 6 corresponding to the positions of each row of crystalline silicon cells, and are electrically connected to the crystalline silicon cells on the upper side.

[0034] In the above, the glass fiber has the following functions: (1) Since the polyethylene terephthalate film, crystalline silicon battery, glass fiber and soft epoxy resin board are all bonded and fixed by adhesive, Before solidification, all the gas needs to be exhausted, so the glass fiber can provide a path for the gas to be exhausted; (2) When ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com