Revolving bed

A rotating bed and liquid phase distribution technology, applied in the field of rotating bed, can solve the problems of no suction capacity, large resistance, easy to block the bed, etc., and achieve the effect of reducing the impact

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

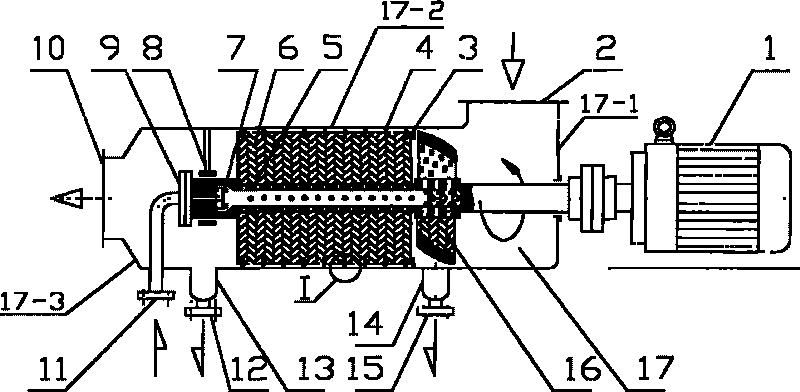

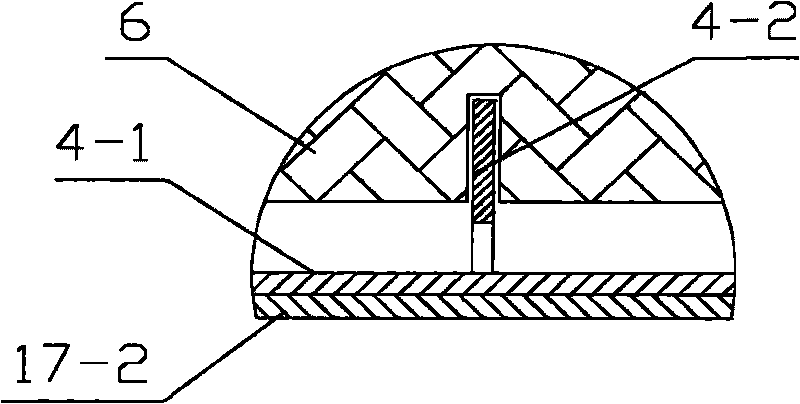

[0019] A rotating bed with a specific structure of the present invention will be described in further detail below in conjunction with the accompanying drawings. Such as figure 1 , 2 , 3, and 4, the gas-liquid self-priming rotary bed of the present invention consists of a rotary bed 6, a composite impeller 16, a centrifugal impeller 7, a liquid phase distribution pipe 5, a rotary joint 9, a support assembly 8, a gas phase inlet 2, a gas phase Outlet 10, liquid phase inlet 11, liquid collecting tank 13, liquid phase outlet 12, gas seal ring assembly 4, mud retaining ring 3, mud collecting box 14, mud discharge port 15, casing 17 and motor 1 etc. constitute.

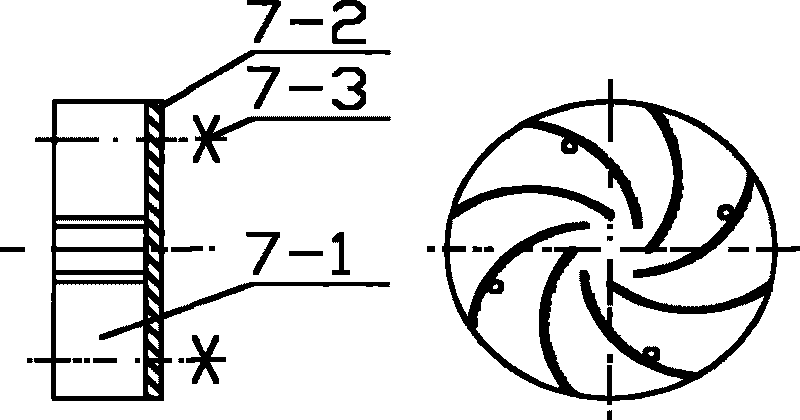

[0020] The rotating bed 6 is made of several layers of sieves, and the existing rotating bed in this field can be used. The composite impeller 16 is composed of a hub 16-1 and several composite blades 16-2; the composite blade is made of steel plate blades with several layers of screens attached; the steel plate blades a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com