Nano fiber and glass fiber composite filter material and preparation method thereof

A technology of glass fiber and nanofiber, which is applied in the field of nanofiber composite glass fiber filter material and its preparation, can solve the problems of limited dust removal efficiency and high cost, and achieve the effects of easy dust removal, improved filtration efficiency and low process cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

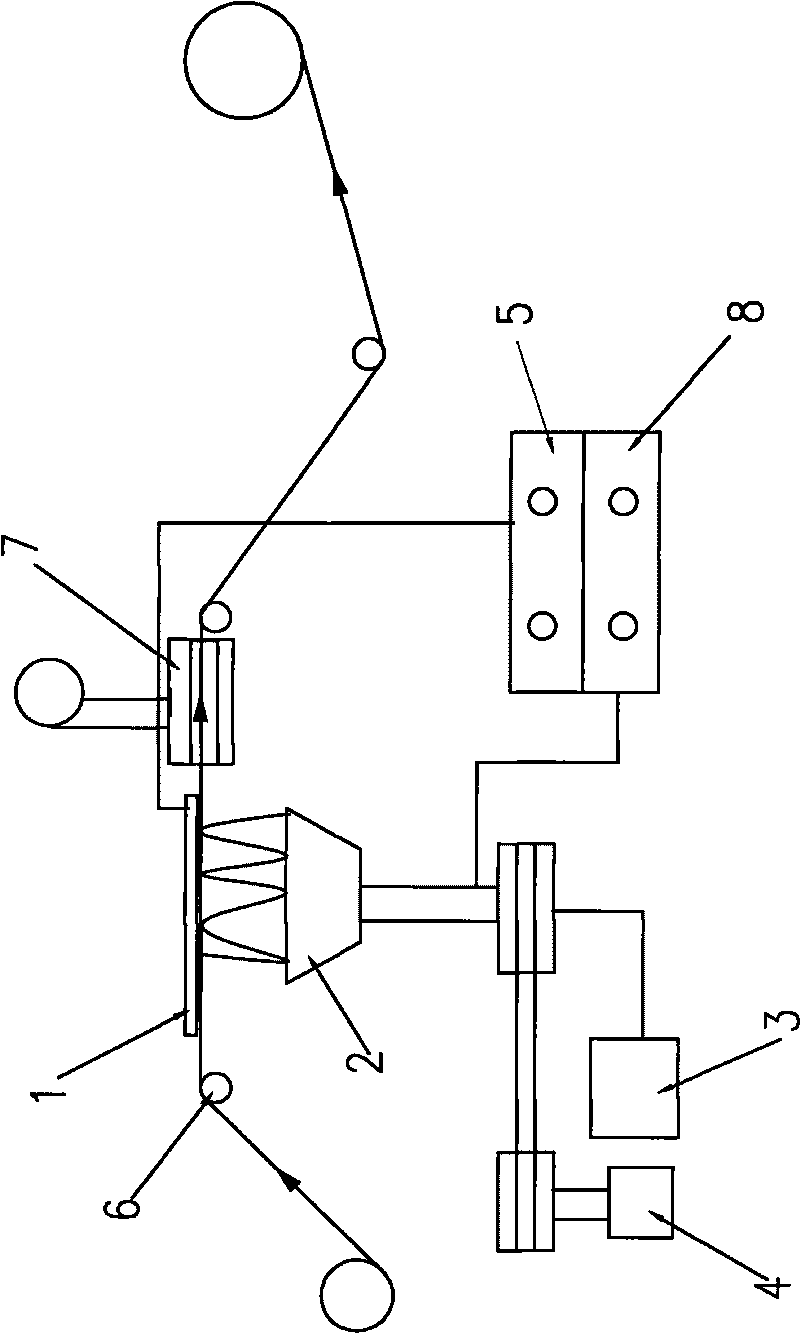

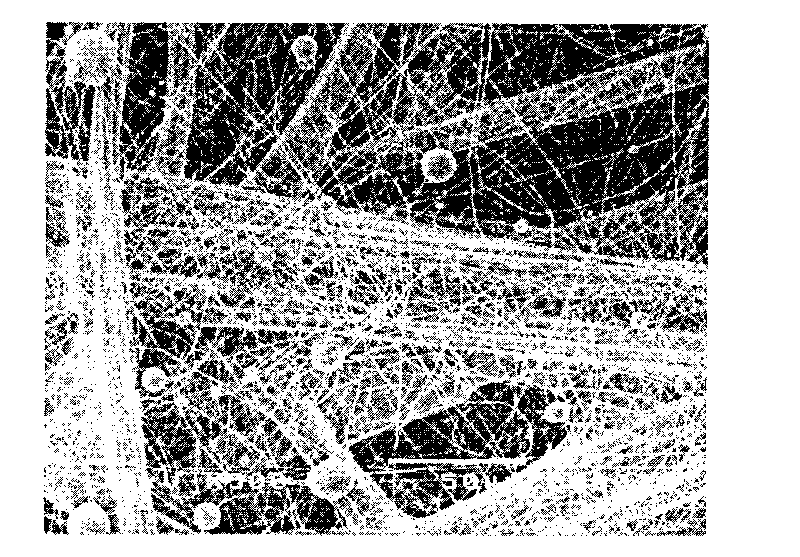

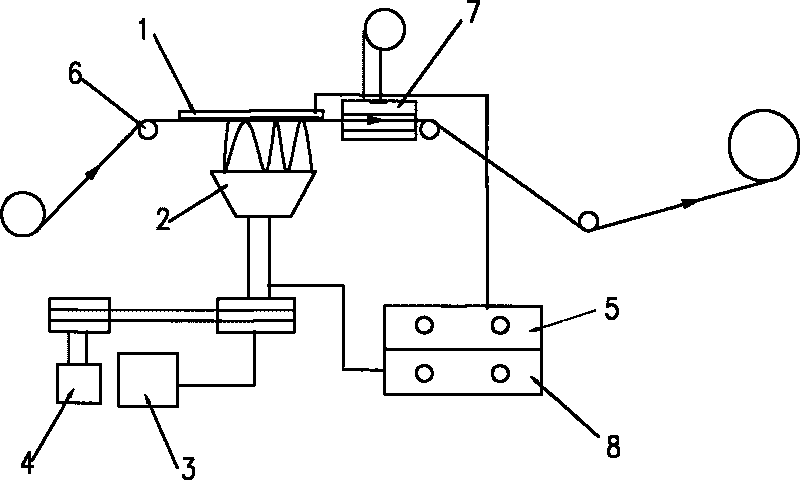

Method used

Image

Examples

specific Embodiment 1~4

[0026] Table 1 is the performance of the glass fiber filter material used in each embodiment of the present invention.

[0027] Table 1:

[0028] sequence

No

project

unit

Example 1

Example 2

Example 3

Example 4

1

5.3cm / s 0.3um efficiency

%

94

98

99.98

99.9995

2

airflow resistance

0.32L / cm 2 .min

Pa

108

170

320

480

3

thickness

mm

0.33

0.33

0.33

0.33

[0029] Table 2 is the process parameter of each embodiment of the present invention.

[0030] Table 2:

[0031]

Centrifugal disc and collector

distance cm

polymer solution

Flow rateml / min

centrifugal disc

rotation speed rpm

Between centrifugal disc and collector

Potential KV

Example 1

62

10

6500

110

Example 2

65

15

7500

...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com