Wiper control system and control method thereof

The technology of a control system and control method is applied in the directions of vehicle cleaning, vehicle maintenance, transportation and packaging, etc., and can solve problems such as inability to return the wiper arm accurately and complex structure, and achieve a simple structure, reliable operation, and low cost. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

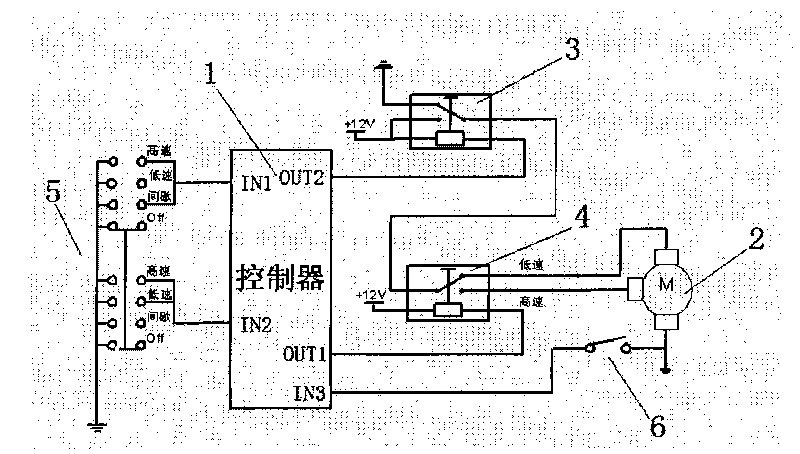

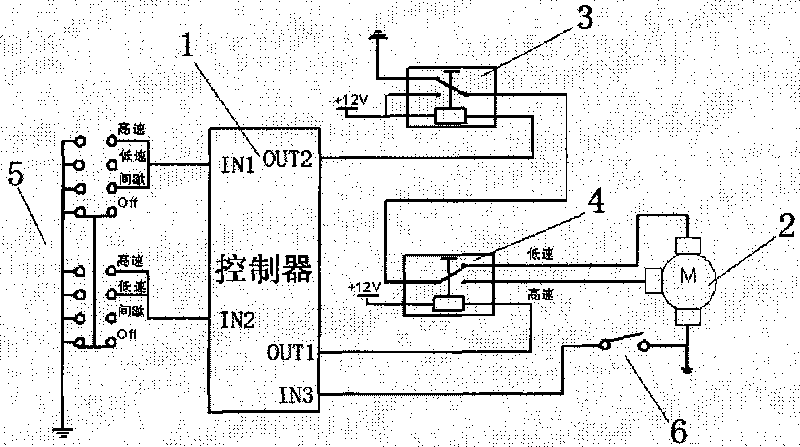

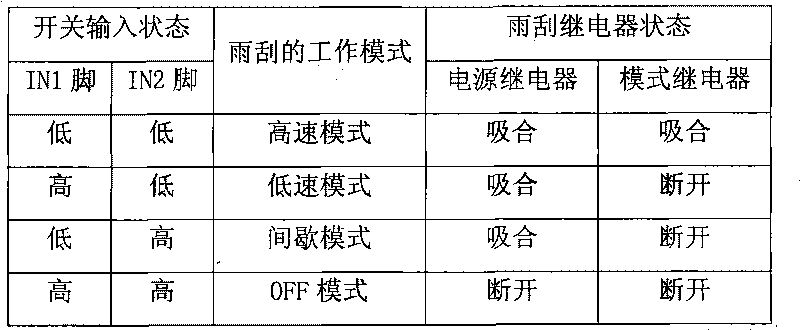

[0015] The wiper control system of this embodiment includes a controller 1 and a wiper motor 2. The controller 1 is a microprocessor with a timing function. The first output terminal OUT1 of the controller 1 controls the mode relay 4, and the second output The pin OUT2 controls the power relay 3. The moving contact of the mode relay 4 is connected with the moving contact of the power relay 3, and the two static contacts of the mode relay 4 are respectively connected with the low-speed switch and the high-speed switch of the wiper motor 2 The two static contacts of the power relay 3 are respectively connected to the 12V power supply and the ground, and the wiper motor 2 is also grounded through its own ground pin.

[0016] The mode selection switch 5 includes two groups of the same mode switch, each group of mode switches are provided with four contacts of high speed, low speed, intermittent, and off at the same position. The mode selection switch 5 also includes one that can contr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com