Aluminum electrolytic tank with novel cathode structure capable of reducing protruding abrasion of cathode

An aluminum electrolytic cell and cathode technology, which is applied in the field of electrolytic aluminum, can solve the problems of low service life, achieve the effects of improving stability, reducing fluctuations in aluminum liquid, and slowing down the flow rate of aluminum liquid

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

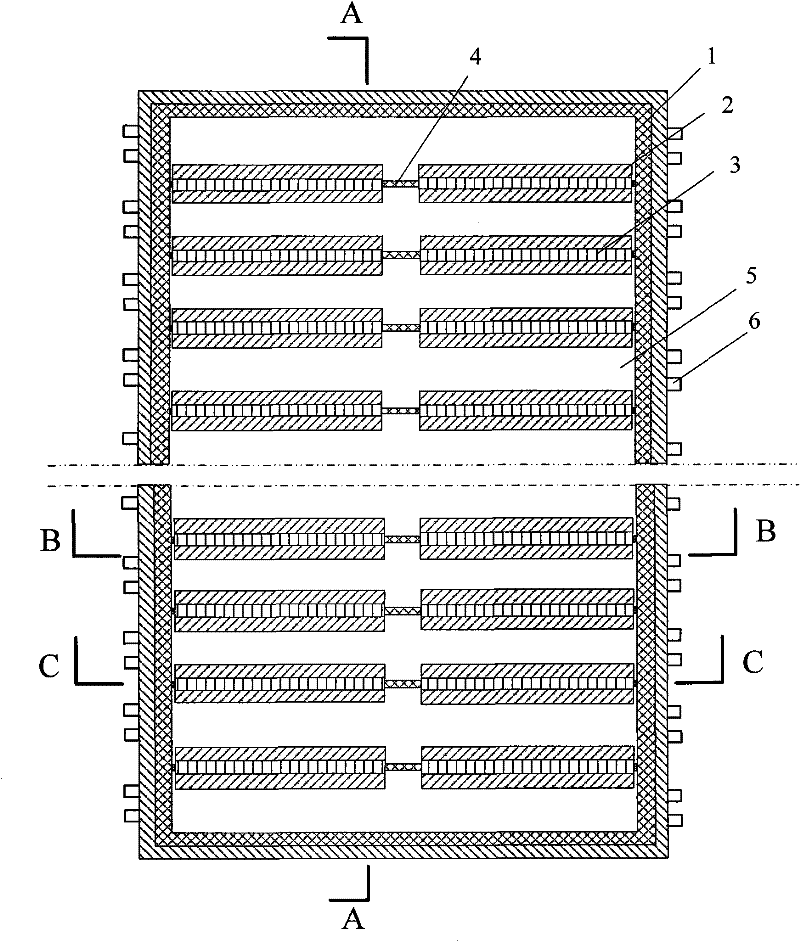

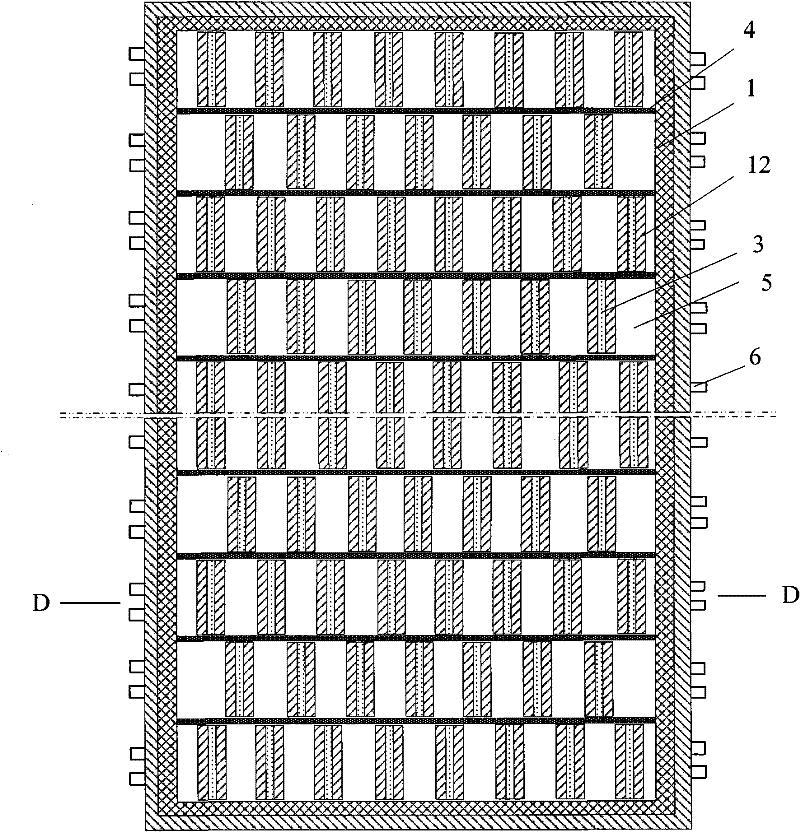

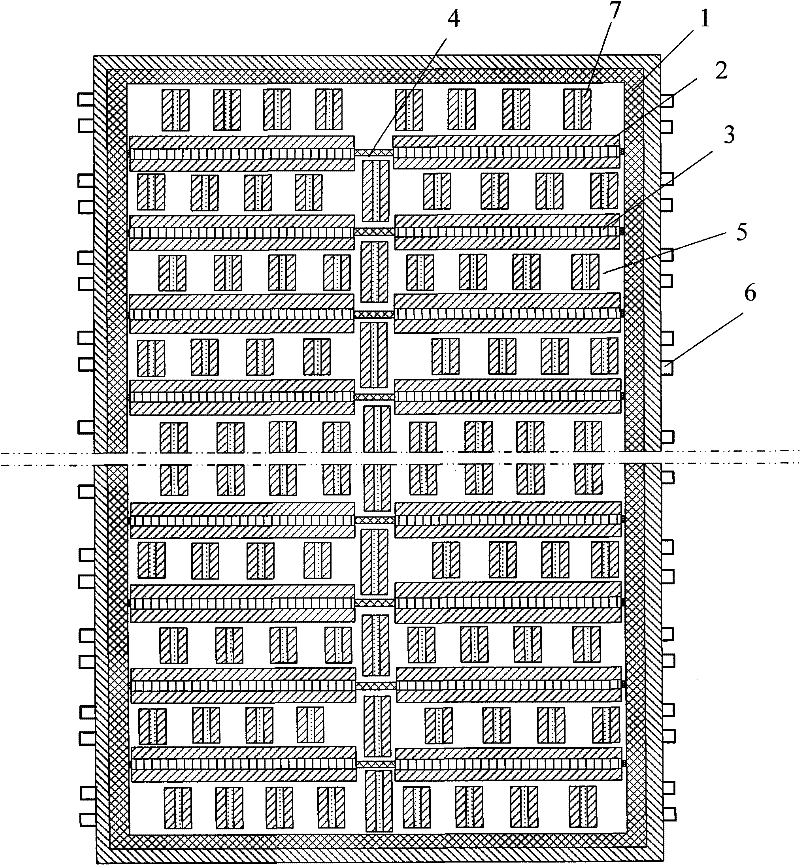

[0027] Aluminum electrolytic cell structure of the present invention is as figure 1 , Figure 5 , Figure 6 , Figure 7 , Figure 11 As shown, in the aluminum electrolytic cell of the present invention, a protruding structure is processed on each cathode carbon block along the lengthwise side, which is called a lengthwise protrusion.

[0028] The edge of the cathode carbon block close to the aluminum outlet of the electrolytic cell near the aluminum outlet is not processed with protrusions.

[0029]The height of the protrusion in the length direction is 14cm, the width is 10cm, and it is located at the edge of each cathode carbon block along the length direction, and the horizontal distance between the outer surface of the length direction protrusion and the edge of the cathode carbon block is 2cm. When slotting, the middle seams of two adjacent cathode carbon blocks are connected with carbon tamping paste. The height of the tamping paste is equal to that of the cathode ca...

Embodiment 2

[0032] Aluminum electrolytic cell structure of the present invention is as figure 1 , Figure 5 , Figure 6 , Figure 7 , Figure 9 As shown, in the aluminum electrolytic cell of the present invention, a protruding structure is processed on each cathode carbon block along the lengthwise side, which is called a lengthwise protrusion.

[0033] The edge of the cathode carbon block close to the aluminum outlet of the electrolytic cell near the aluminum outlet is not processed with protrusions.

[0034] The height of the protrusion in the length direction is 18cm, the width is 15cm, and it is located at the edge of each cathode carbon block along the length direction, and the horizontal distance between the outer surface of the length direction protrusion and the edge of the cathode carbon block is 3cm. When slotting, the middle seams of two adjacent cathode carbon blocks are connected with carbon tamping paste. The height of the tamping paste is equal to that of the cathode ca...

Embodiment 3

[0037] Aluminum electrolytic cell structure of the present invention is as figure 1 , Figure 5 , Figure 6 , Figure 7 , Figure 10 As shown, a protruding structure is processed along the lengthwise side of each cathode carbon block, which is called lengthwise protrusion.

[0038] The edge of the cathode carbon block close to the aluminum outlet of the electrolytic cell near the aluminum outlet is not processed with protrusions.

[0039] The height of the protrusion in the length direction is 10cm, the width is 5cm, and it is located at the edge of each cathode carbon block along the length direction, and the horizontal distance between the outer surface of the length direction protrusion and the edge of the cathode carbon block is 1cm. When slotting, the middle seams of two adjacent cathode carbon blocks are connected with carbon tamping paste. The height of the tamping paste is equal to that of the cathode carbon block, and then the upper surface of the two adjacent cat...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com