Railway construction machine guard rail hoisting device and rail replacing locomotive guard rail hoisting device

A technology for construction machinery and rail protection, applied in the directions of roads, tracks, laying tracks, etc., can solve the problems of long operation time, inclination or excessive gauge, and high requirements for lifting equipment, so as to reduce site requirements and equipment requirements. , to achieve the effect of wheel set and track alignment, reducing the number of workers

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

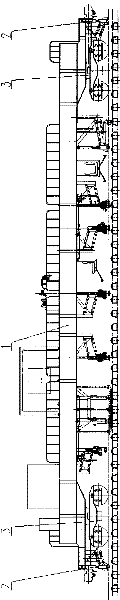

[0035] A rail guard lifting device for a seamless rail track change vehicle, such as figure 1 As shown, it includes a guard rail lifter 2 arranged under the body 1 of the running mechanism of the rail changing vehicle, capable of lifting and moving the body 1 of the rail changing vehicle as a whole, and a guard rail lifter 2 arranged on each bogie 3 of the rail traveling machine. An anti-off device that vertically fixes the bogie 3 and the car body 1, and the bogie 3 is a welded frame type bogie.

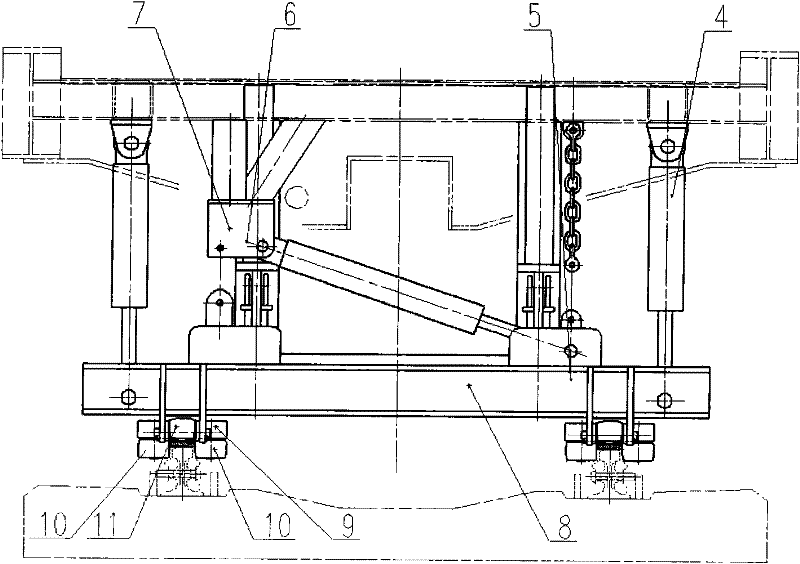

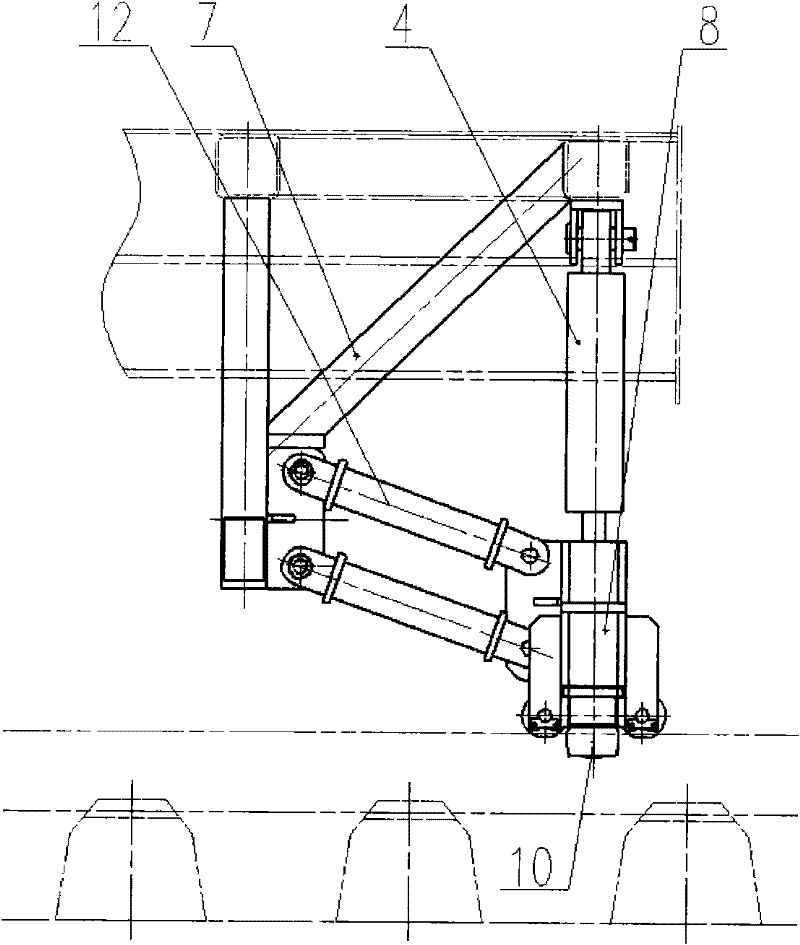

[0036] Guard rail lifter 2 such as Figure 2-4 As shown, it is arranged under the car body 1 of the traveling mechanism of the track changing operation vehicle, as shown in figure 1 As shown, it includes a strip-shaped support body 8 arranged perpendicular to the traveling direction of the car body 1, a guardrail hanger 7 that fixes the support body 8 under the car body 1, and a control device for controlling the movement of the support body 8. Both ends of the body 8 are respecti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com