Safe pressure relief device

A pressure relief device and a safe technology, applied in the components of the pumping device for elastic fluid, liquid variable capacity machinery, pump control and other directions, can solve the problems of motor coil burning, damage to related parts, high pressure shock, etc. Achieve the effect of low manufacturing cost, simple structure, easy assembly and maintenance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] According to the technical means of the present invention, the implementation modes suitable for the present invention are listed below and described in conjunction with the drawings as follows:

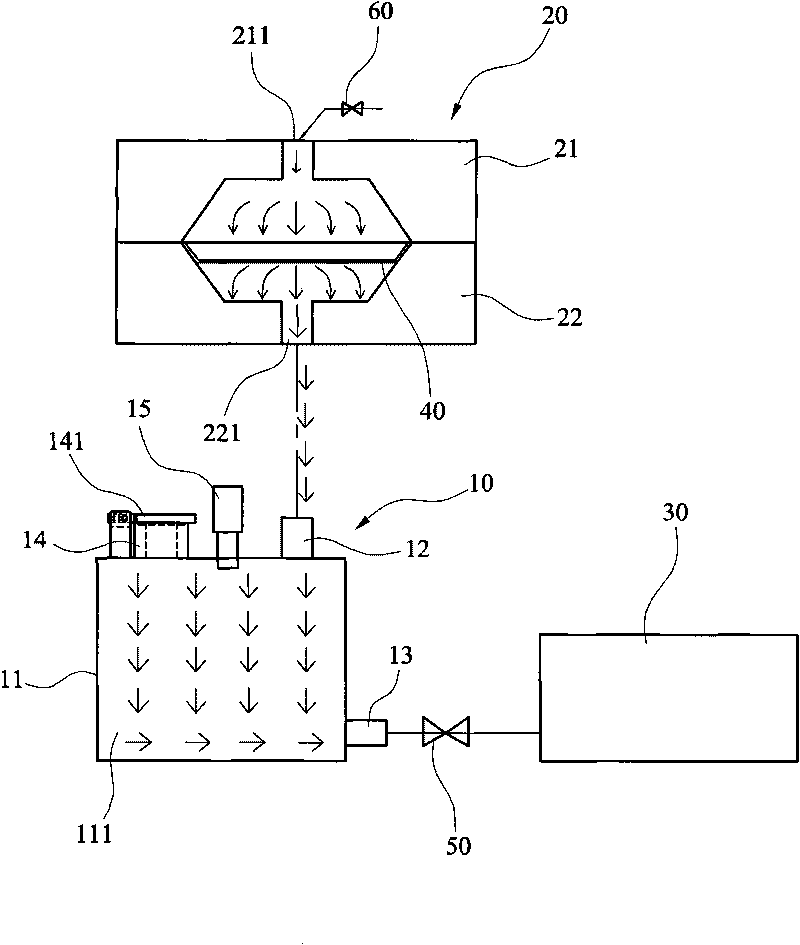

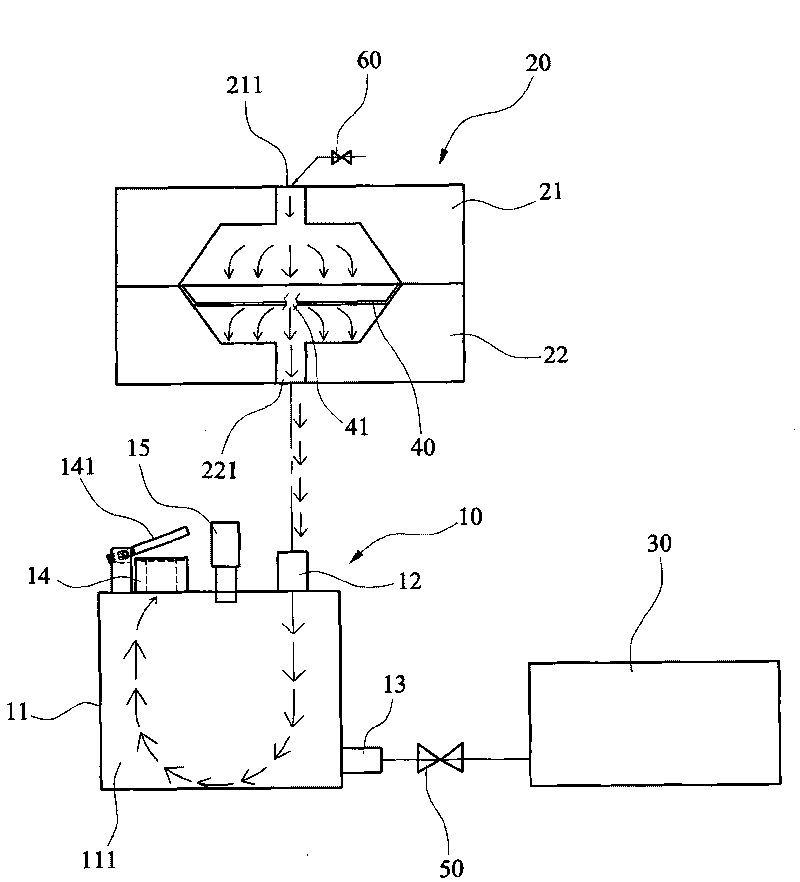

[0028] see figure 1 , is a schematic diagram of the erection configuration of the first embodiment of the present invention. The figure discloses a safety pressure relief device 10 that is connected in series between the high pressure forming system 20 and the vacuum pump 30 .

[0029] The high pressure forming system 20 includes an upper mold 21 clamped on the film 40 and a lower mold 22, wherein the upper mold 21 provides high-pressure gas to push the film 40, and the lower mold 22 includes a negative pressure end 221 for vacuuming , so that the film 40 can be closely attached to the lower mold 22 for forming.

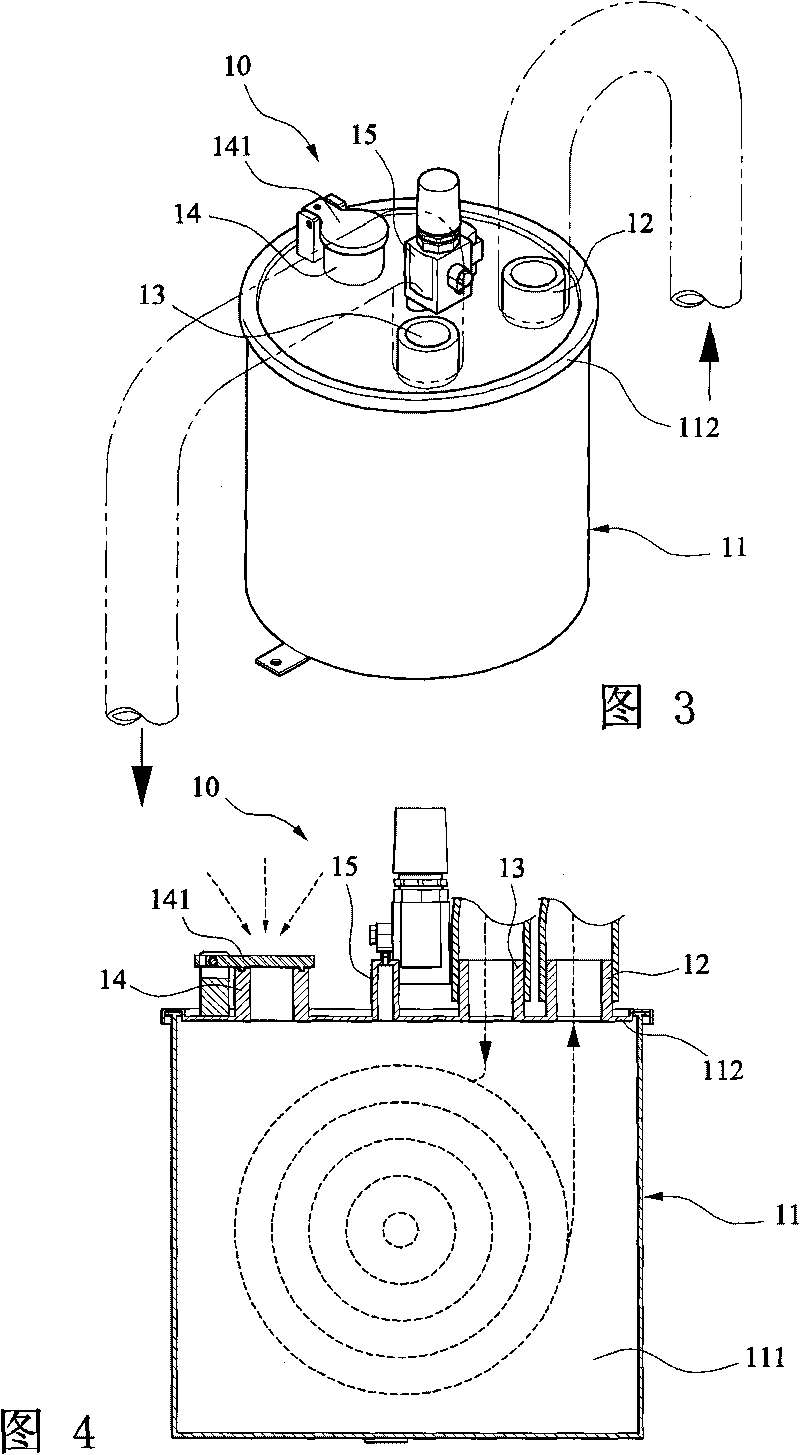

[0030] The safety pressure relief device 10 has a hollow cylinder 11 , and the cylinder 11 contains an accommodating space 111 . A suction port 12 connected to the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com