Input/fore bearing of automobile engine

An automobile engine and front bearing technology, applied in the direction of ball bearings, bearing components, shafts and bearings, etc., can solve the problems of failing the test, unable to meet the use requirements of high-power 4G9 engines, and achieve the improvement of bearing capacity and fatigue life. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] Below in conjunction with accompanying drawing and specific embodiment the present invention will be further described:

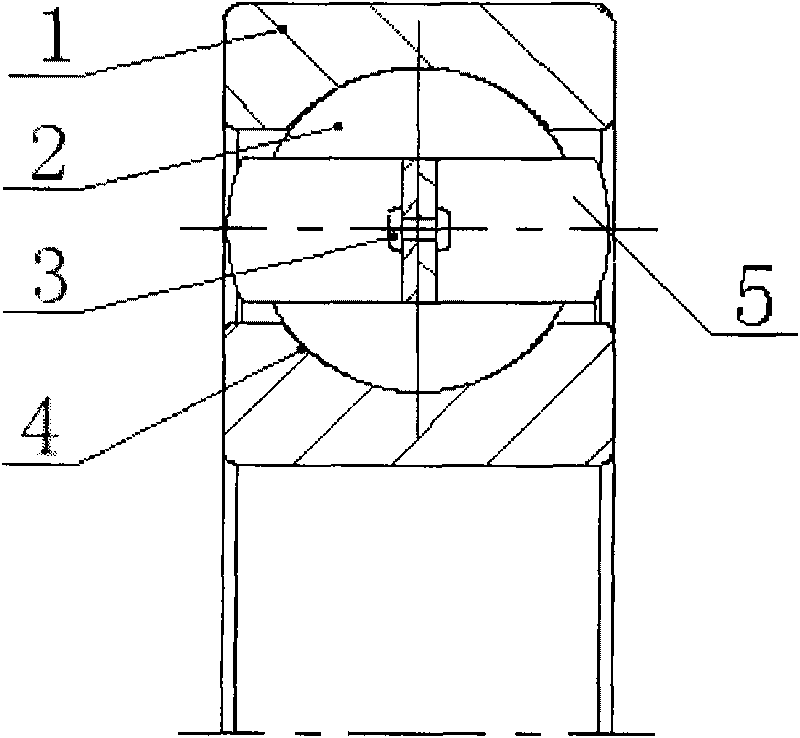

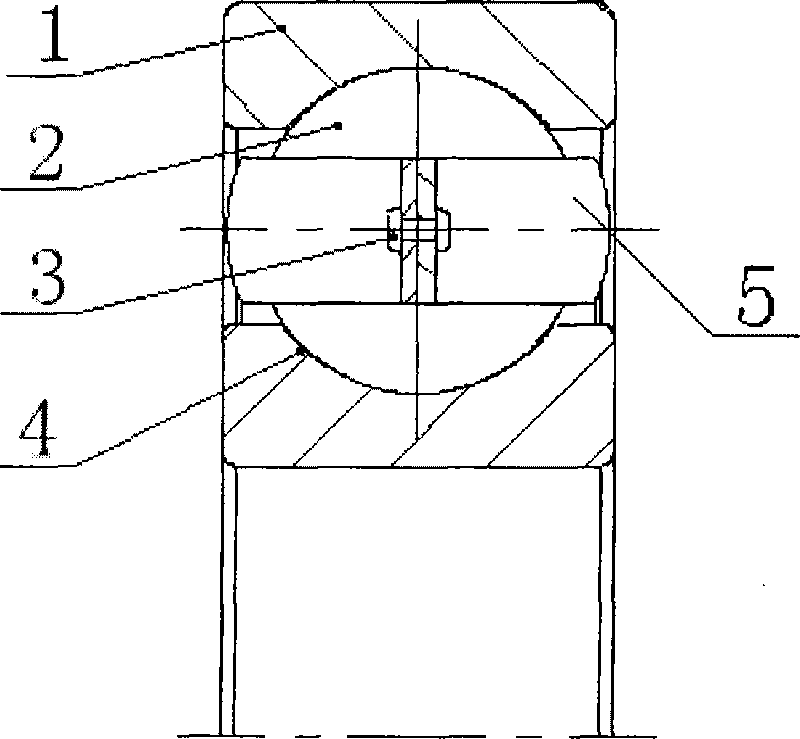

[0016] combine figure 1 , this embodiment includes an inner ring 4, an outer ring 1, and a steel ball 2 with an enlarged diameter arranged in the inner ring 4 and the outer ring 1, and the cage 5 is fixed by a flat head rivet 3. The surface of the ferrule raceway is modified, and the surface of the inner raceway is carburized; at the same time, the diameter of the steel ball in this embodiment is 15.081.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com