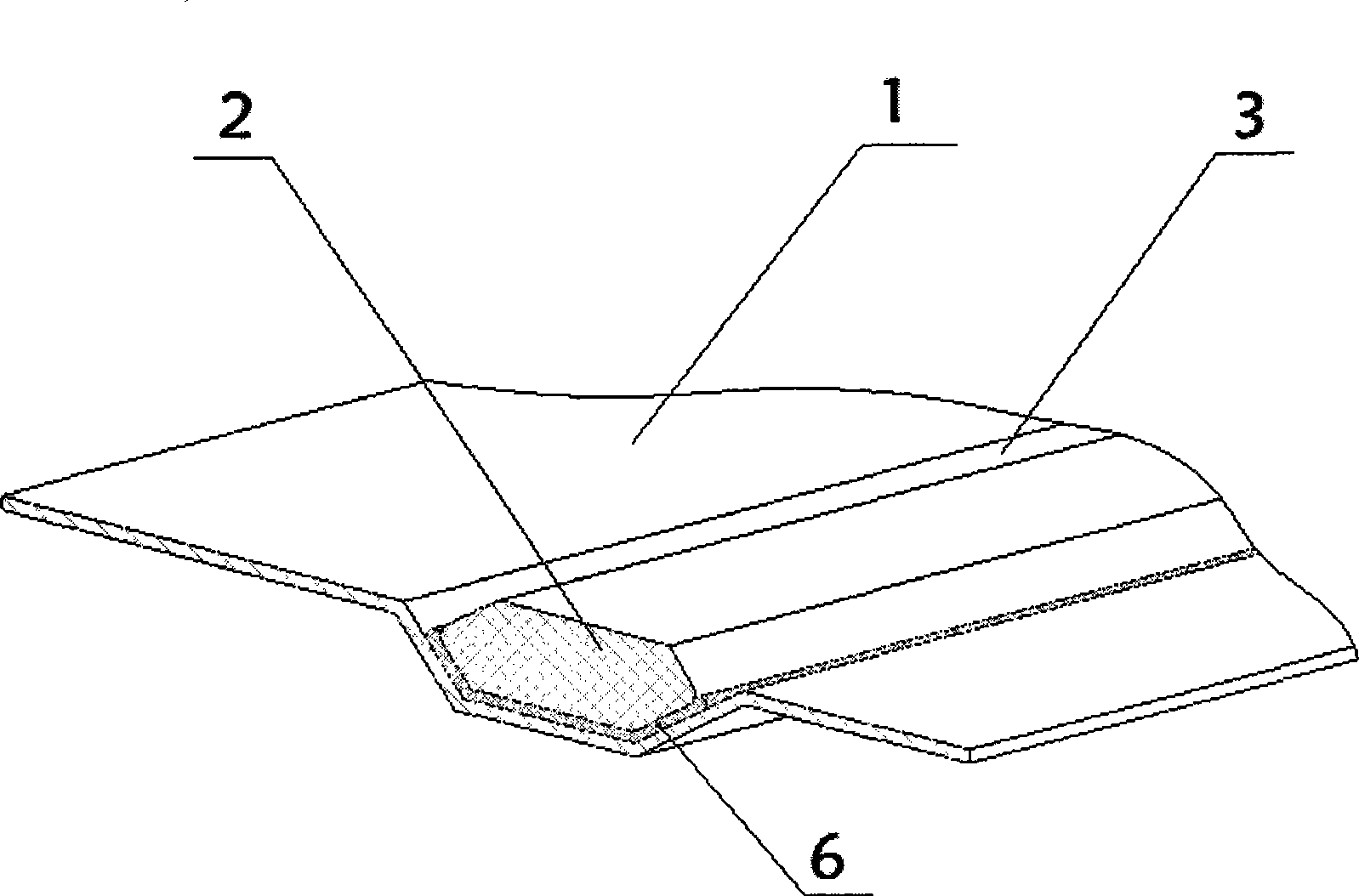

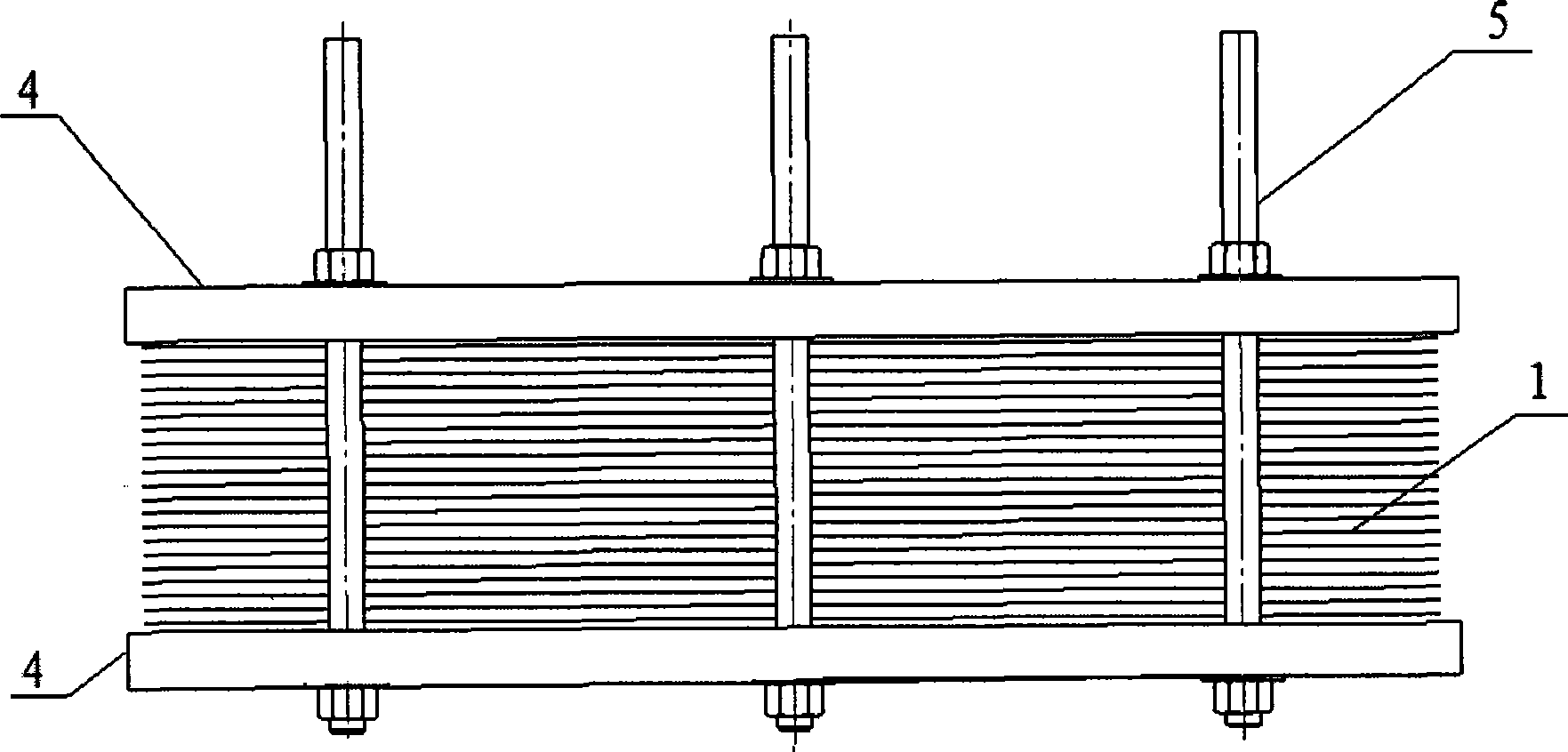

High-temperature solidification bonding method of spacer and plate in plate type heat exchanger

A plate heat exchanger, high temperature curing technology, applied in the direction of heat exchanger shell, indirect heat exchanger, heat exchanger type, etc., can solve the problems of unprofessional personnel, weak bonding performance, easy deformation, etc. The effect of reducing the cost of use, saving social wealth, and stabilizing the bonding performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The high temperature curing bonding method is achieved through the following steps:

[0022] 1. Cleaning process: After the plate is pressed and blanked, it is cleaned with alkaline water (using alkaline cleaning agent "degreasing two-in-one") to remove oil and other substances on the surface of the plate. The concentration of alkaline water is 7% to 10%, and it is heated To 100°C, wash for 40 minutes, then wash with clean water to remove the alkaline water on the surface of the plate, take it out, put it in a drying oven and dry it with hot air at 150°C, keep it for 30 minutes, take it out and lower it to room temperature, so that the surface of the plate is dry and clean.

[0023] 2. Glue application process: Take the 3M1469 glue of the American "3M" company from the 7°C freezer—referred to as 3M glue (3MScotch-Weld 1469 is a one-component epoxy resin adhesive, which has good high-temperature curing performance and has good adhesion to metals. Very high strength and i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com