Wavefront measurement method and device based on multiple-pinhole plate

A technology of wavefront measurement and pinhole plate, applied in the direction of measuring device, measuring optics, optical radiation measurement, etc., can solve the problems affecting the speed of wavefront measurement, unfavorable application, etc., to simplify the recording process, reduce system cost, and easy to prepare Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0041] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

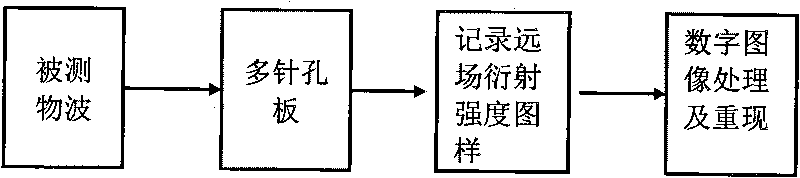

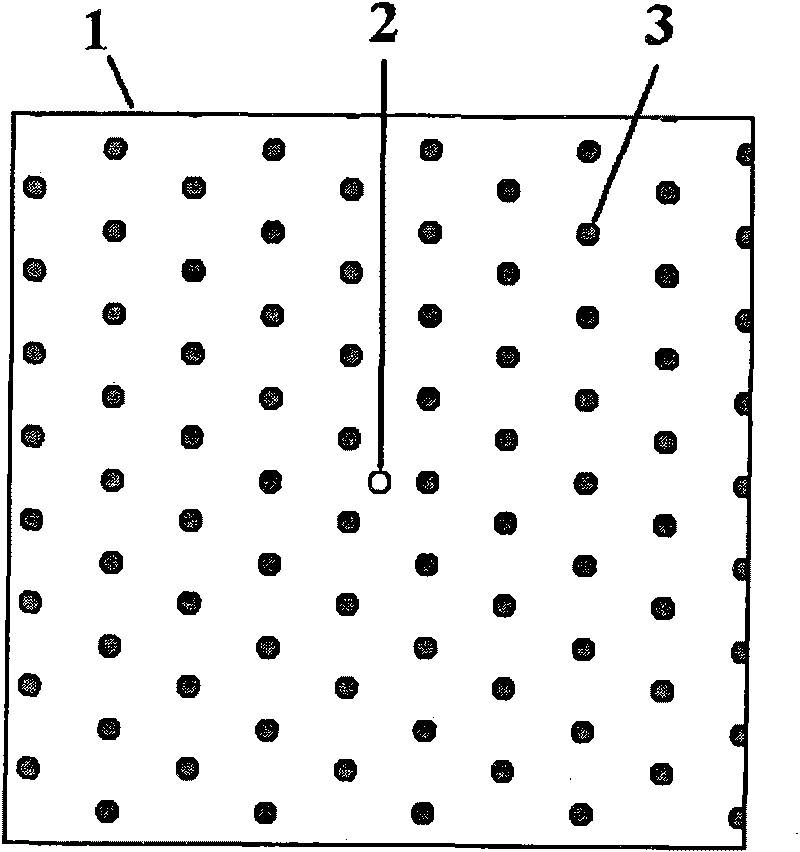

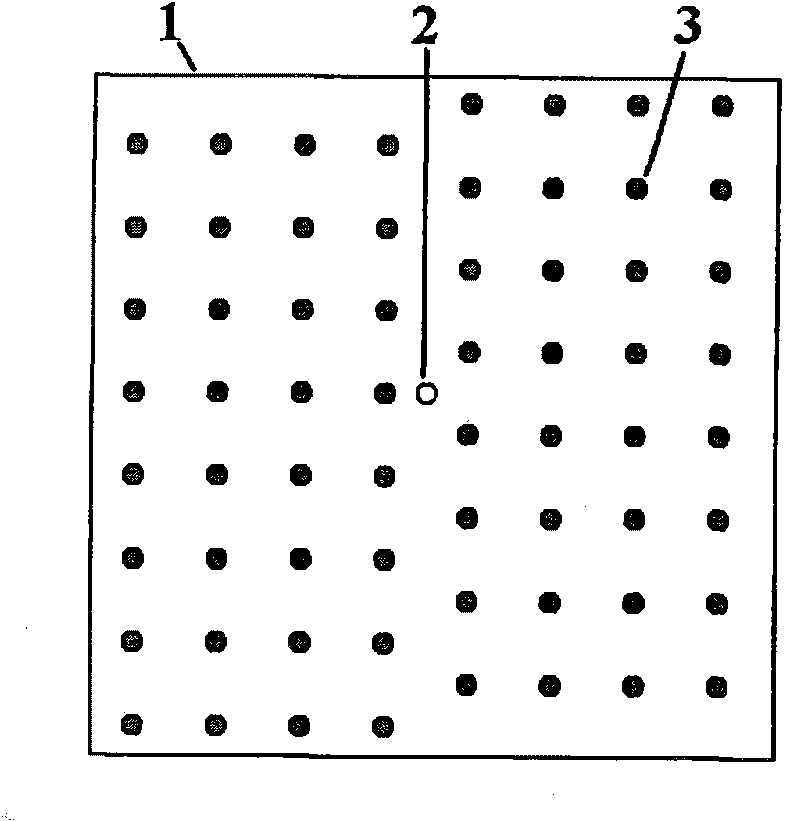

[0042] like figure 1 As shown, the inventive method comprises the following steps: (1) at first sampling the wavefront of the measured object wave with a multi-pinhole plate 1, the pinholes on this multi-pinhole plate 1 are composed of a reference pinhole 2 and several (2) The object wave passing through the multi-pinhole plate 1 continues to propagate, and forms a Fraunhofer diffraction light field in the far field (or in the back focal plane of the lens after passing through a Fourier transform lens). (3) record the Fraunhofer diffraction intensity pattern of the object wave through the multi-pinhole plate 1 with a two-dimensional image sensor 4 (such as CCD); (4) utilize image processing technology to the Fraunhofer diffraction intensity pattern The pattern is inversely Fourier transformed to obtain the correlation function pattern of the complex am...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com