Cable connector assembly

A cable connector and component technology, applied in the direction of connection, connecting device parts, conductive connection, etc., can solve problems such as unfavorable terminal and cable welding, increase connector port size, etc., achieve easy welding, reduce height, Simple process effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

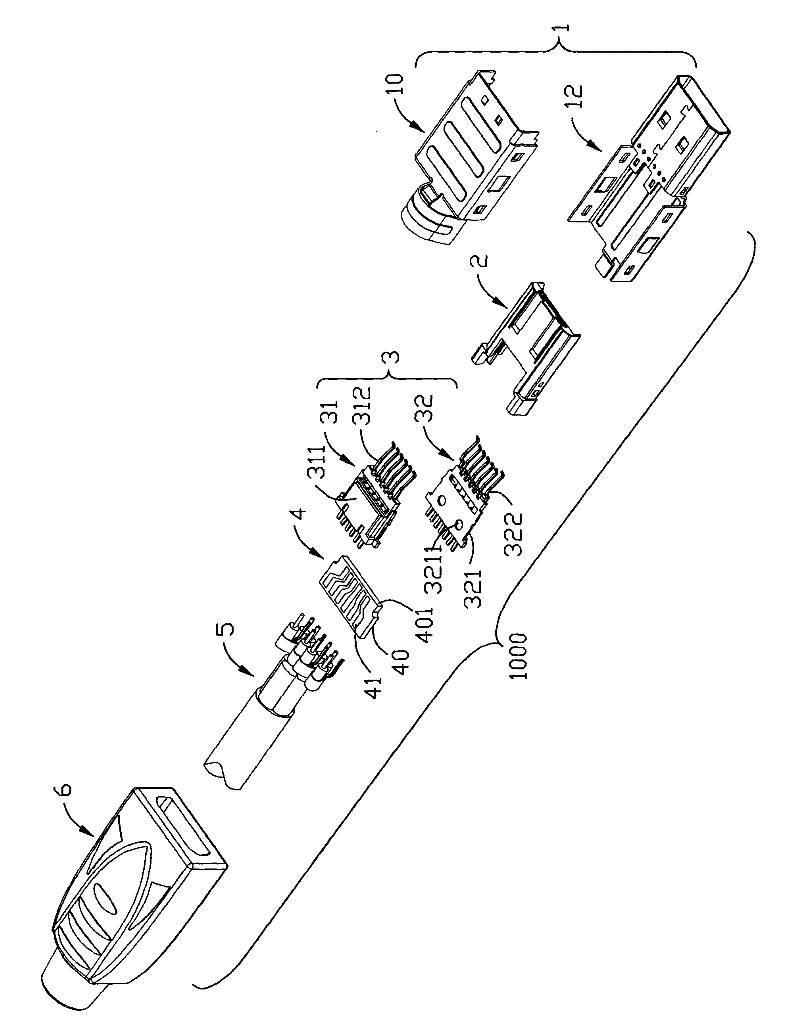

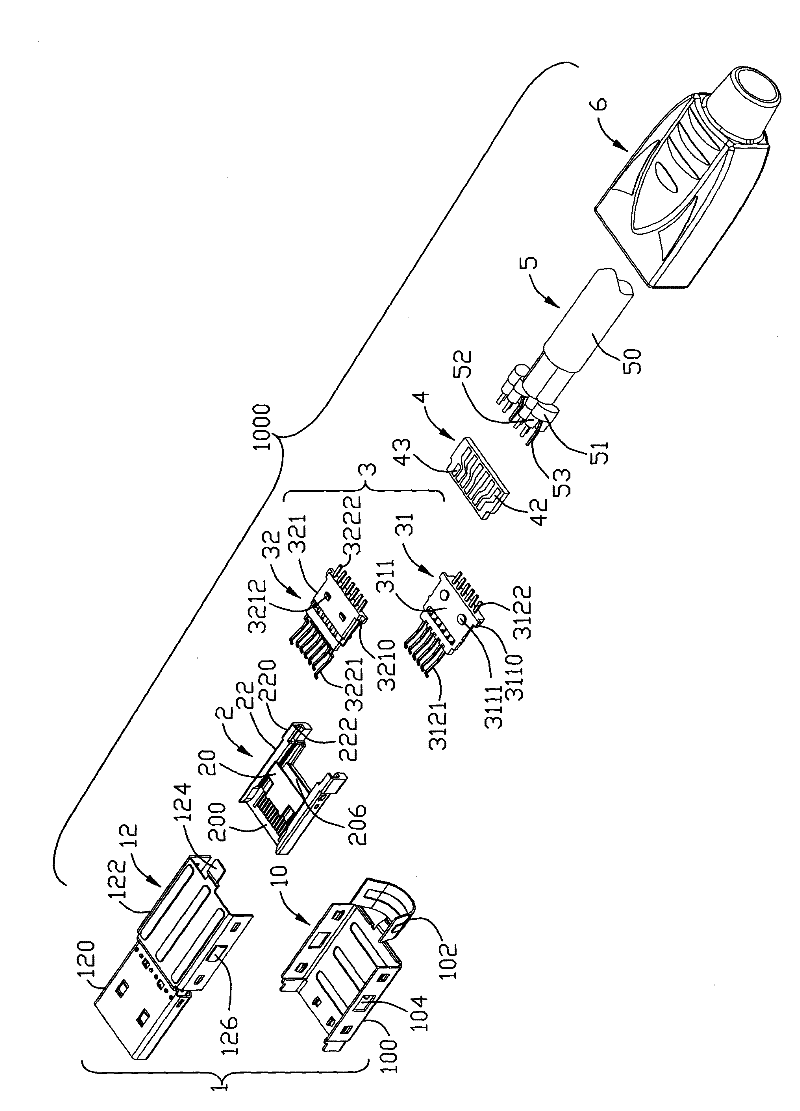

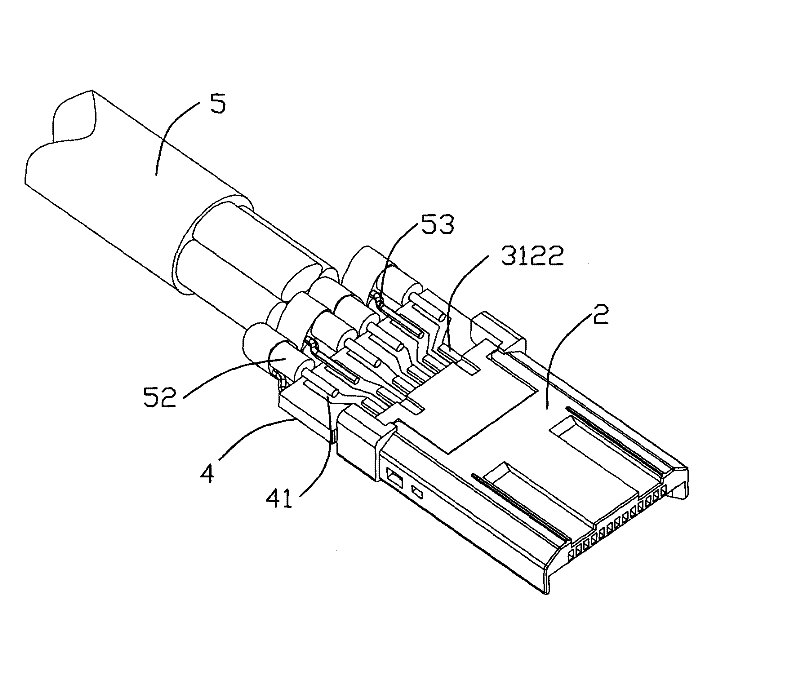

[0017] see Figure 1 to Figure 7 , the cable connector assembly 1000 of the present invention includes a metal shell 1 , an insulating body 2 , a terminal module 3 , a circuit board 4 , a cable 5 and a shell 6 .

[0018] The metal shell 1 includes a first shielding shell 10 and a second shielding shell 12 . The first shielding shell 10 has a main body portion 100 with a substantially U-shaped cross section and a curled portion 102 connected to a rear edge of the main body portion 100 . The second shielding shell 12 has a frame portion 120 with a substantially rectangular cross section, a substantially inverted U-shaped main body portion 122 extending backward from the frame portion 120 , and a protruding piece 124 formed on the rear edge of the main body portion 122 . The first shielding shell 10 and the second shielding shell 12 are combined together, wherein the protrusion 126 formed on the side surface of the main body part 122 of the second shielding shell 12 is snapped t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com