12-pole external-rotor capacitor-run asynchronous motor

A technology for asynchronous motors and external rotors, applied in the direction of asynchronous induction motors, electrical components, electromechanical devices, etc., can solve the problems of 12-pole motor vibration and noise, and achieve the effects of reducing winding temperature rise, reasonable distribution, and ingenious design

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

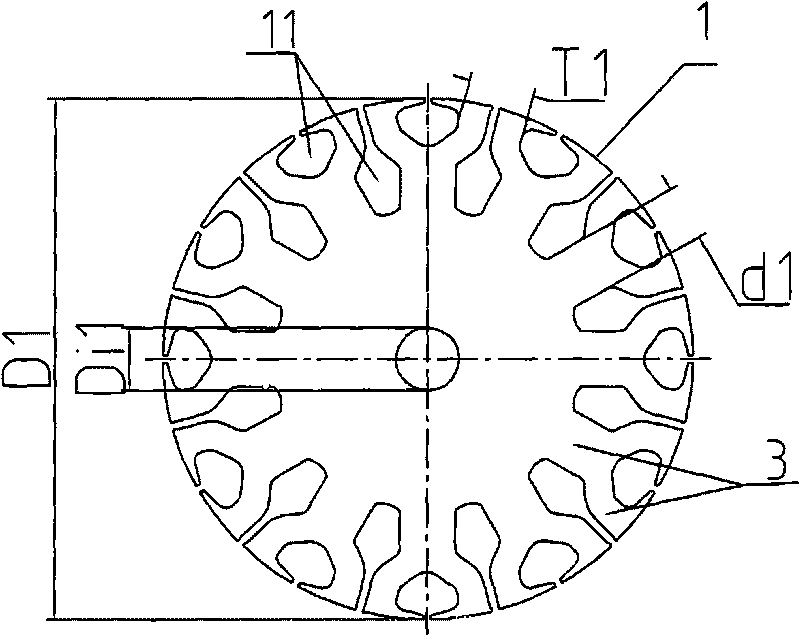

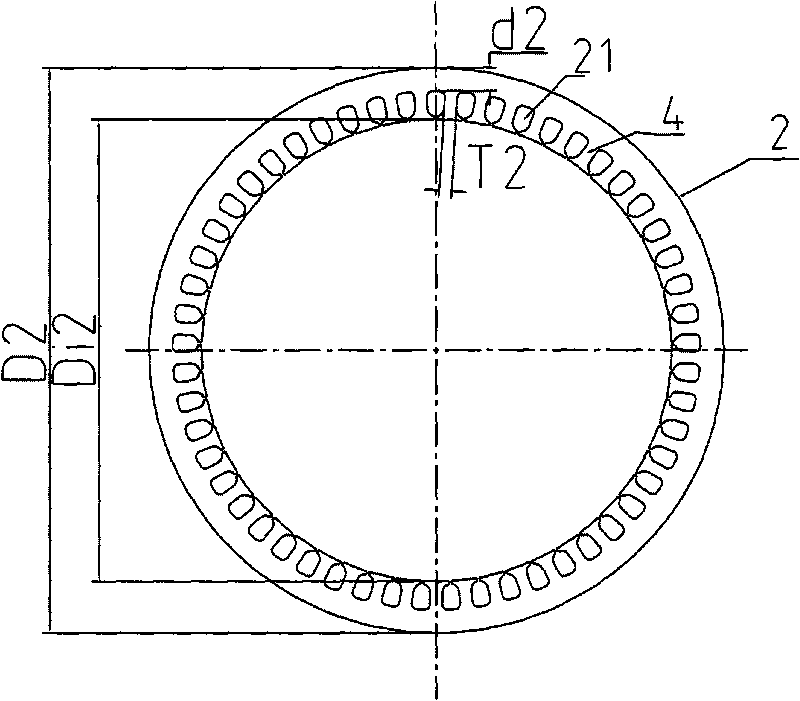

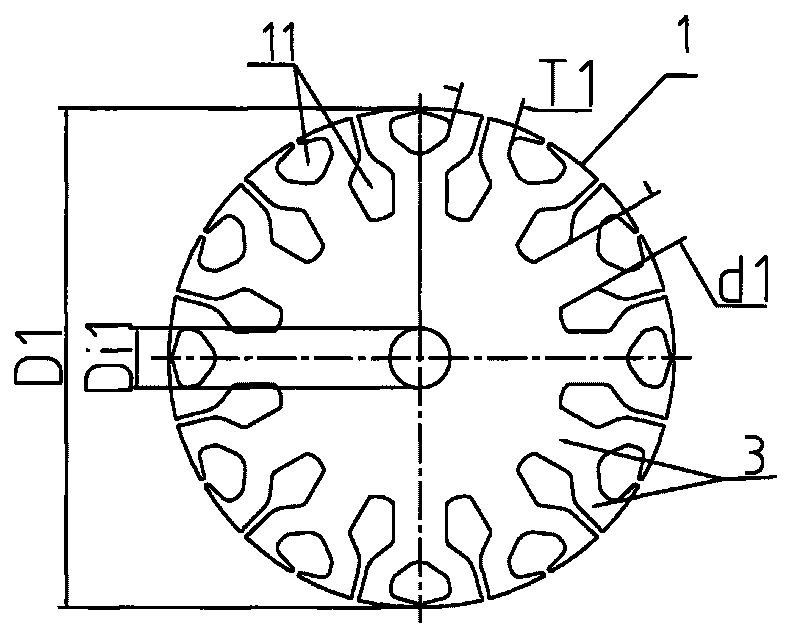

[0019] The structure diagram of the present invention is as figure 1 , 2 As shown, it includes the motor stator 1 installed on the motor shaft and the motor rotor 2 set on the outside of the motor stator 1. The number of stator slots 11 of the motor stator 1 is 24, of which the number of main winding slots and auxiliary winding slots 12 each, the ratio of the number of stator slots of the motor stator 1 to the number of rotor slots 21 of the motor rotor 2 is 0.30.7. In this embodiment, the ratio of the number of stator slots of the motor stator 1 to the number of rotor slots 21 of the motor rotor 2 is 0.5.

[0020] The ratio of the stator outer diameter D1 of the motor stator 1 to the rotor outer diameter D2 of the motor rotor 2 is 0.68˜0.95. In this embodiment, the ratio of the stator outer diameter D1 of the motor stator 1 to the rotor outer diameter D2 of the motor rotor 2 is 0.75.

[0021] The ratio of the tooth width dimension T1 of the outer teeth of the stator to the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com