Operating method of water purifier

A technology of water purification device and operation method, which is applied in the direction of chemical instruments and methods, permeation/dialysis water/sewage treatment, membrane, etc., which can solve the problem that clogging substances cannot be fully peeled off, achieve reliable removal, and increase the number of cleanings.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

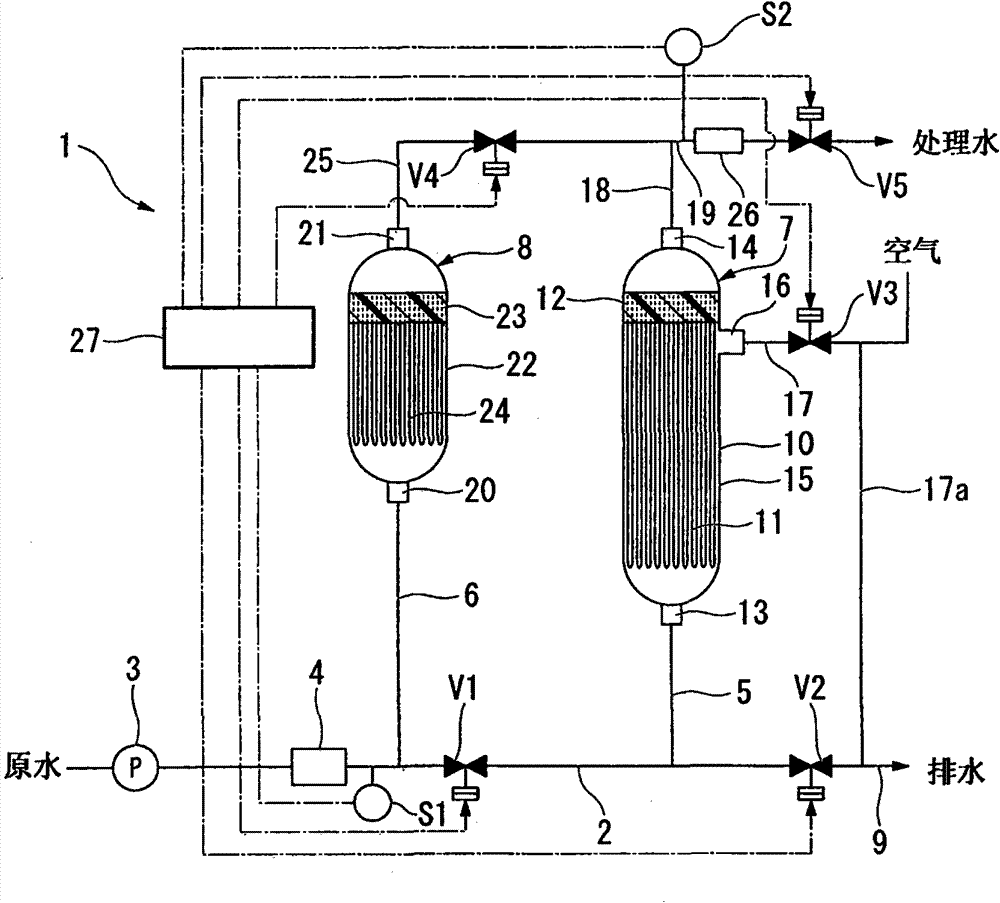

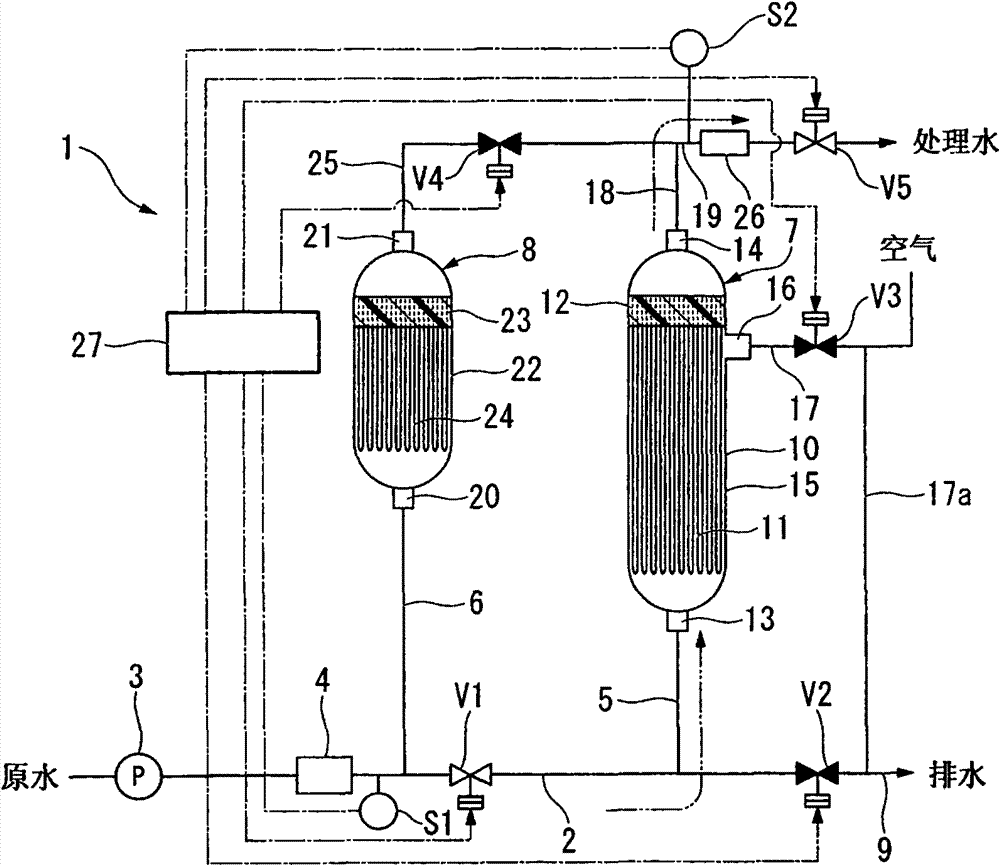

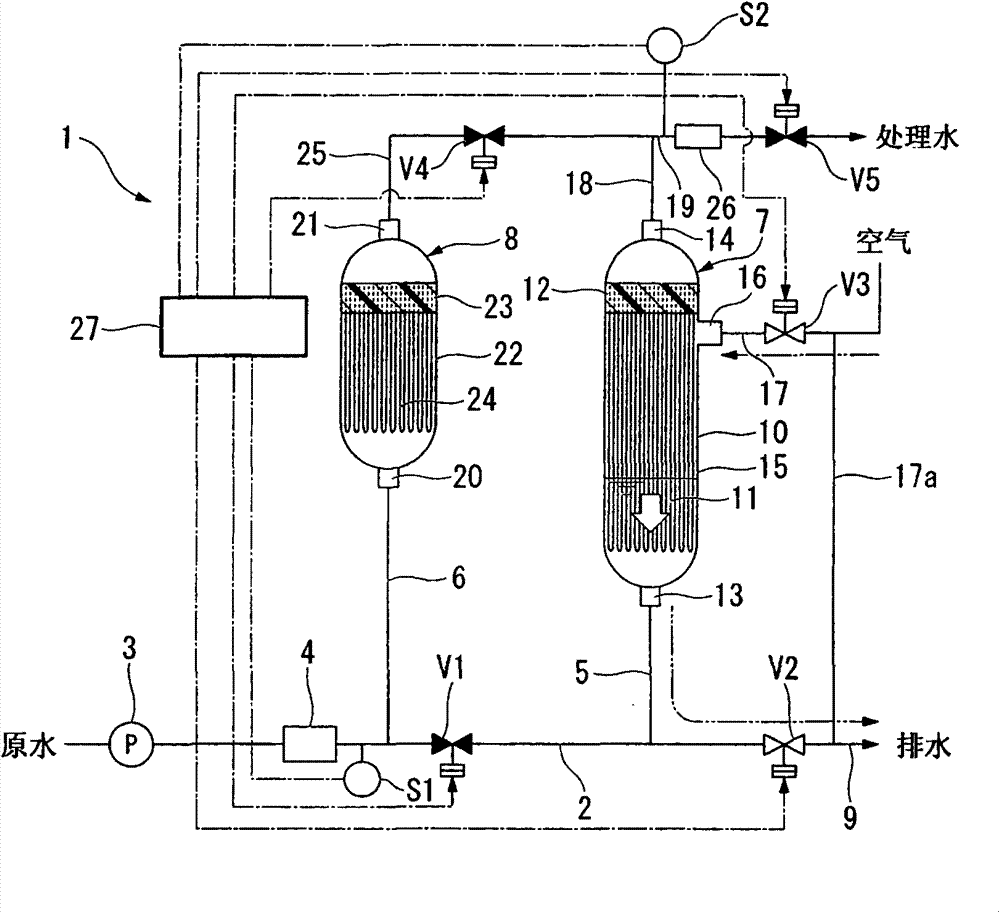

[0033] Below, refer to Figure 1 to Figure 5 An example of the embodiment of the present invention will be described.

[0034] figure 1 It is a water purifier 1 for filtering raw water. Depending on the area used, river water, lake water, well water, industrial water, etc. are supplied as raw water through waterways. On the main raw water supply flow path 2 of the water purifier 1, a pump 3 for boosting the water pressure in the waterway, and a downstream pump 3 for stabilizing the water pressure output by the pump 3 are installed. Pressure reducing valve 4. In addition, the booster pump 3 does not necessarily need to be operated, and when the inflow pressure of the raw water is high, the pump 3 may not be provided.

[0035] The main raw water supply flow path 2 is branched and connected to a first raw water supply flow path 5 and a second raw water supply flow path 6. A first membrane filtration unit 7 is connected to the first raw water supply flow path 5, and a second membran...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com