Anti-freezing and heat-insulating fire-fighting liquid tank

A fire-fighting liquid and liquid tank technology, which is applied to tank trucks, transport buses, heat storage heaters, etc., can solve the problems of water pump system valves freezing and unable to open and close, and achieve the effect of reducing the possibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

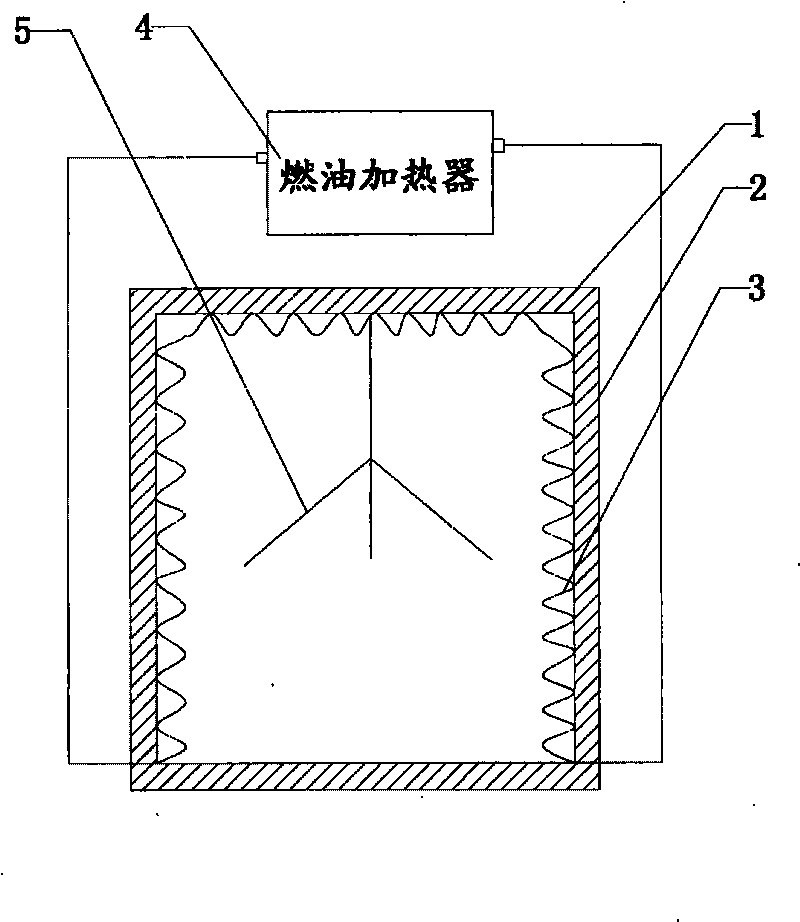

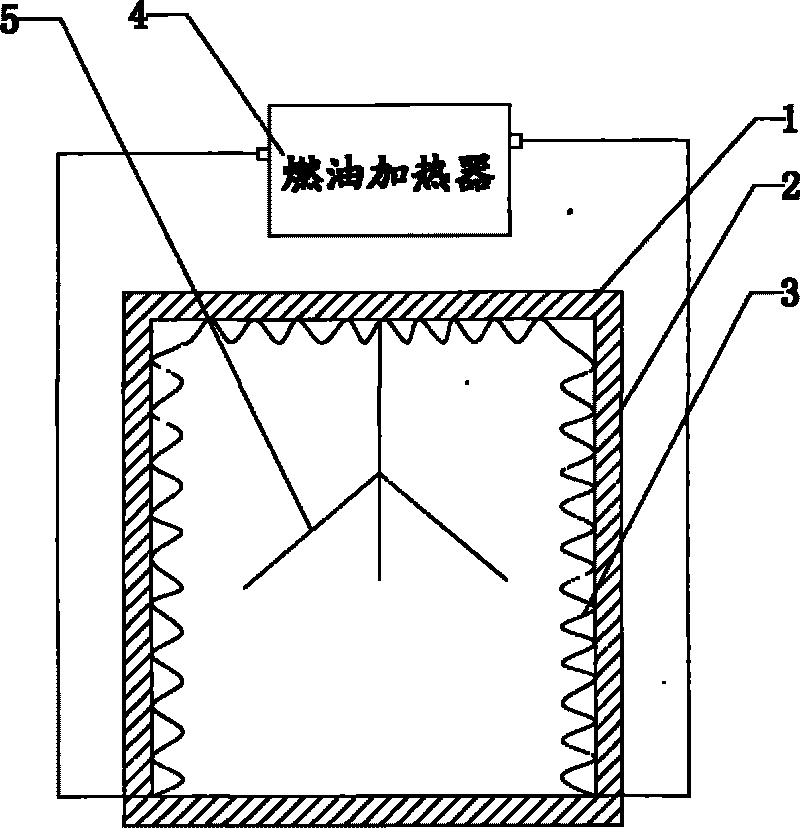

[0010] In the antifreeze and heat preservation fire fighting liquid tank described in the embodiment of the present invention, a layer of skeleton is pasted on the outer wall of the fire fighting liquid tank body, the inside of the skeleton is filled with a rigid foam polyurethane insulation layer 1, and the outside of the skeleton is bonded with an aluminum plate or Steel plate protective layer 2; the inner wall of the liquid tank body is laid with several sets of serpentine metal heat dissipation pipes 3 in series or in parallel, and the two ends of the metal heat dissipation pipes 3 groups are respectively connected with the fuel heater 4 arranged at an appropriate position outside the liquid tank body The water outlet of the fuel heater 4 is connected to the water return port. The fuel heater 4 can work in a temperature control, remote control or wire control mode. When the fuel heater 4 is working, the water pump on the fuel heater 4 drives the hot water in the heat dissipa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com