Organic waste gas treatment equipment

A technology for processing equipment and organic waste gas, which is applied in separation methods, dispersed particle separation, chemical instruments and methods, etc., can solve the problems of reduced adsorption capacity of activated carbon, complex process, huge processing equipment, etc., and achieves environmental protection, resource saving and operating costs Small, low operating pressure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

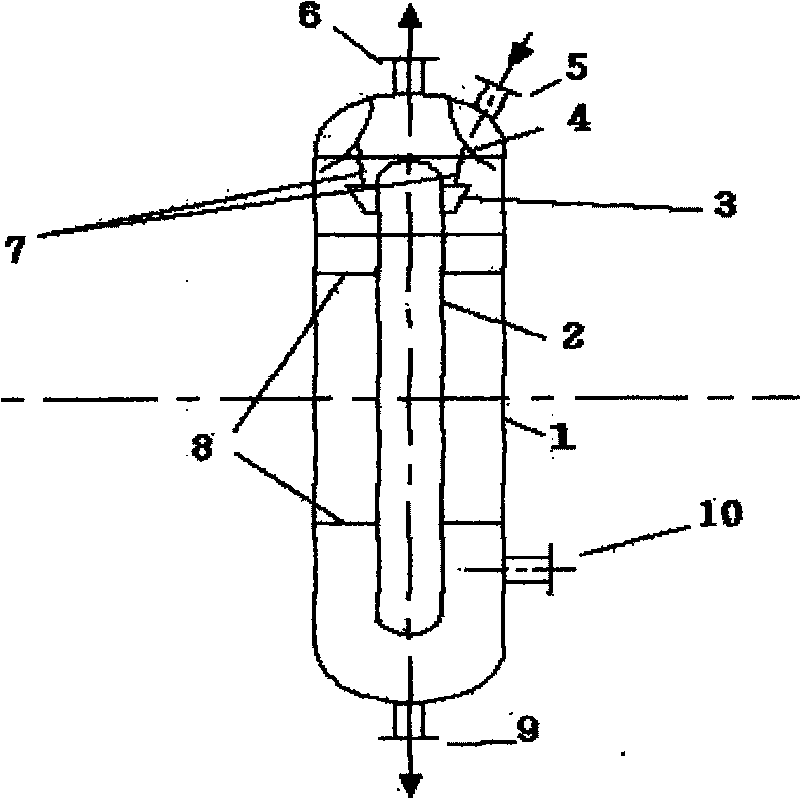

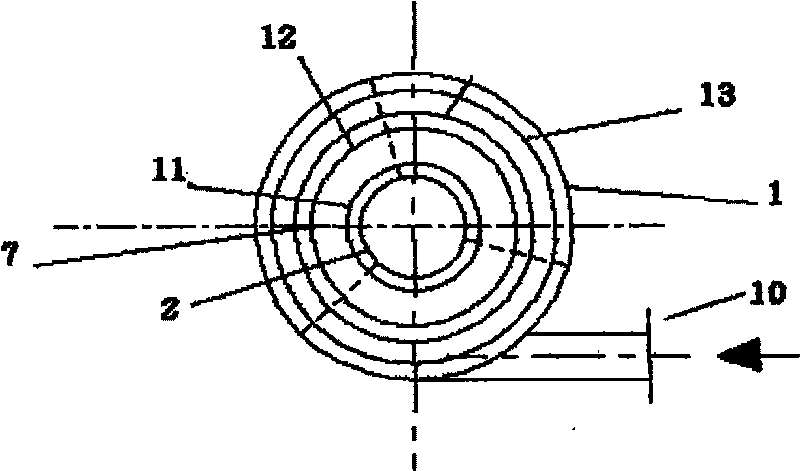

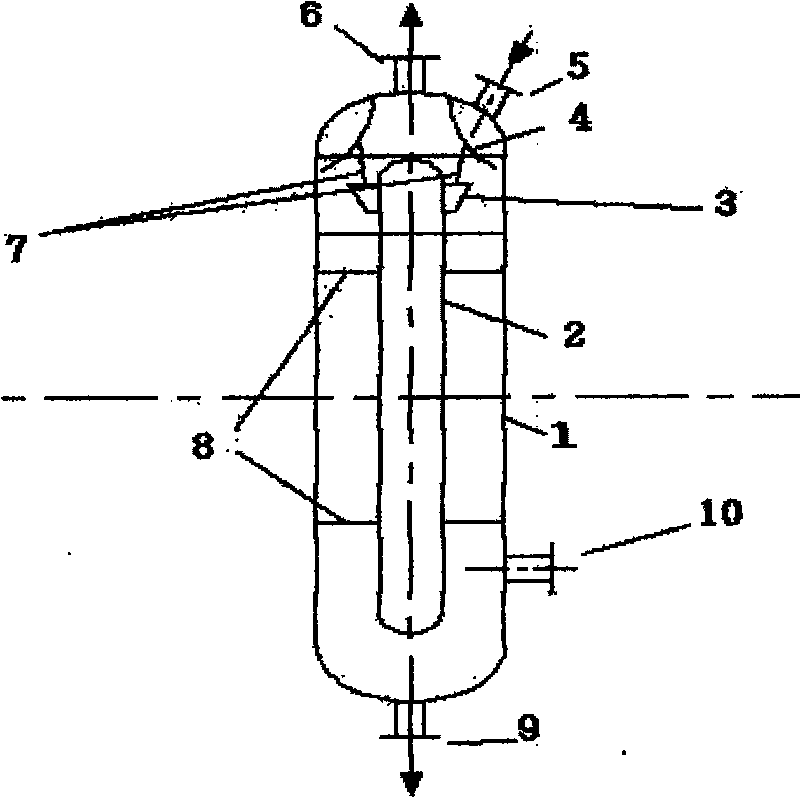

[0023] The following will be further described in conjunction with the accompanying drawings, not to limit the scope of the present invention.

[0024] see figure 1 and figure 2 As shown, the present invention includes a tower body 1 and an inner cylinder 2. The organic waste gas enters the interior of the tower body 1 through the gas inlet 10, and spirally rises along the inner wall of the tower body 1 under the action of centrifugal force. The inner cylinder 2 is mainly for stabilizing the direction of the air flow. The outer wall of the inner cylinder 2 also has a certain absorption effect. The absorbent is added from the top of the tower body 1 through the absorbent inlet 5, part of the absorbent is sprayed to the inner wall of the tower body 1 through the outer distributor 4 and descends along the wall surface, and part of the absorbent flows into the inner distributor 3 through the conduit 7 and flows along the inner wall. The outer wall of the cylinder 2 descends. T...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com