Technological process for treatment of waste gas containing caffeine

A process flow and exhaust gas treatment technology, applied in separation methods, organic chemistry, dispersed particle separation, etc., can solve the problems of huge processing equipment, decreased adsorption capacity of activated carbon, complicated process, etc., and achieve low operating costs, low operating pressure, and environmental protection. The effect of protecting resource saving

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

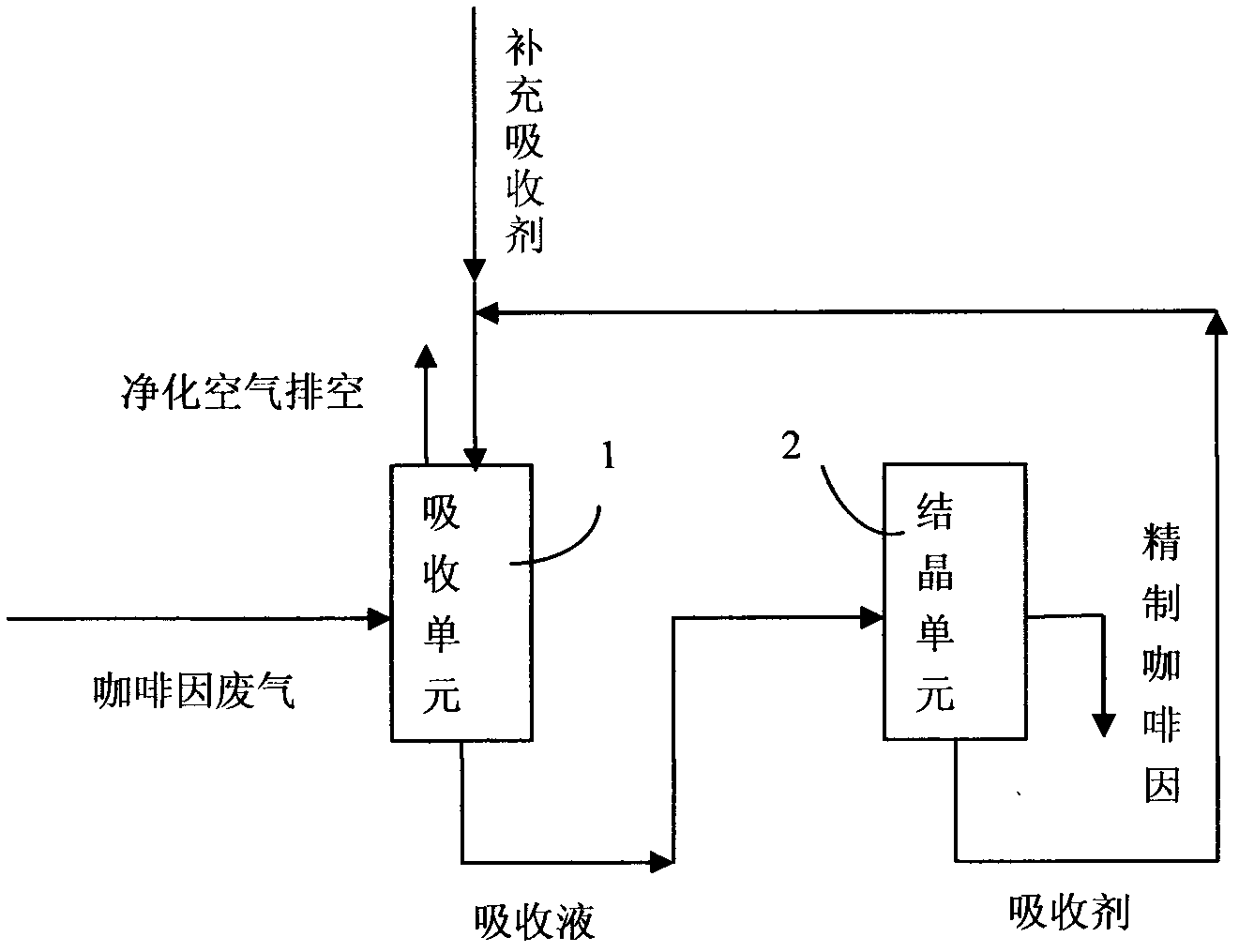

[0023] The following will be further described in conjunction with the accompanying drawings, not to limit the scope of the present invention.

[0024] Referring to the drawings, the whole process includes an absorption unit 1 and a crystallization unit 2 .

[0025] The absorption unit 1 absorbs the caffeine in the caffeine-containing exhaust gas to purify the air and obtain a mixture of caffeine and absorbent. The equipment used in the absorption unit 1 is a self-developed cyclone wetted wall tower, its absorption efficiency is higher than that of the traditional absorption device, and the pressure drop before and after the treated mixed gas passes through the device is lower than that of the traditional absorption device, so the absorption Unit 1 is an energy efficient unit.

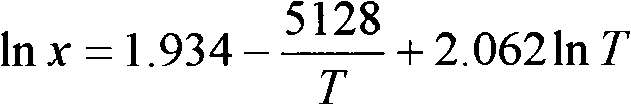

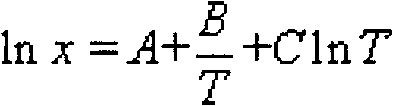

[0026] The basic data involved in the absorption process of the absorption unit 1 mainly include mass transfer coefficient correlation formula and pressure drop correlation formula. However, the infl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com