A method for pickering-based emulsion solids transport in a microreactor system

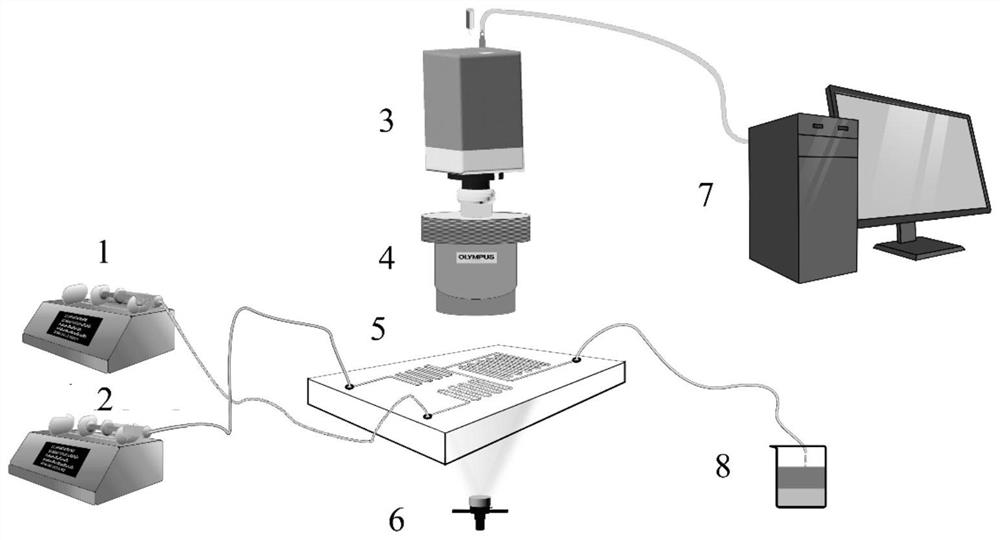

A technology of microreactor and microchannel reactor, which is applied in the field of microfluidics, can solve the problems of small solid catalyst particles, easy adhesion, and large surface energy, and achieve the effect of eliminating wall effect, easy transportation, and continuous process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

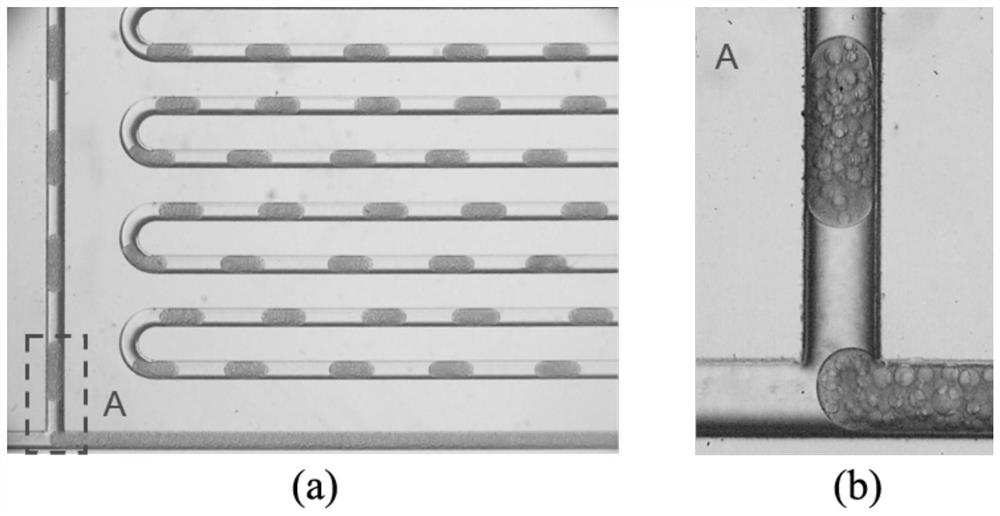

[0033] In order to verify the effect of the present invention, quartz glass was selected as the material of the microreactor, the cross-sectional size of the channel was 0.3 mm×0.3 mm, and a T-shaped convection microchannel was used. In order to better observe the flow pattern, a small amount of Sudan red was added to ethyl acetate for staining.

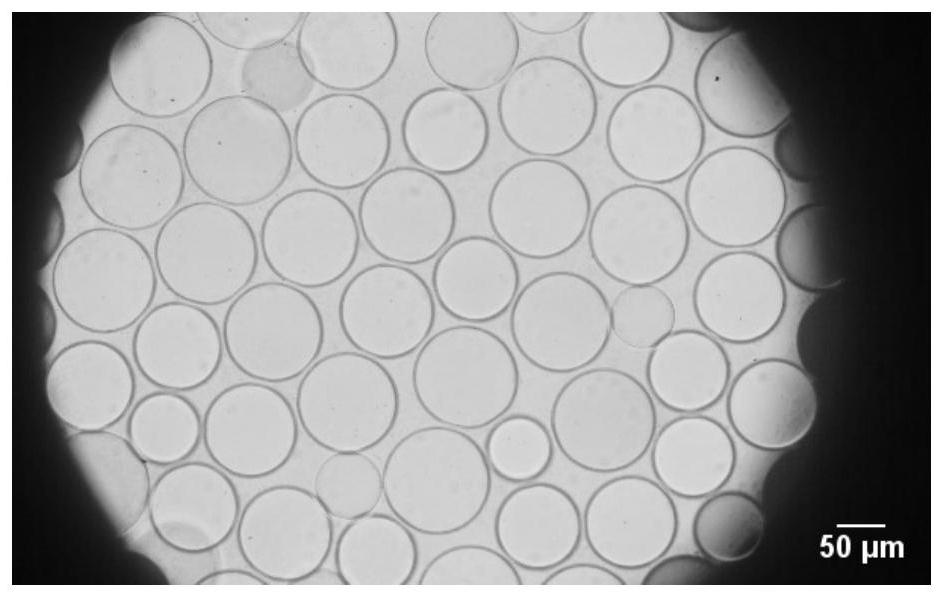

[0034] Before the experiment, the Pickering emulsion was prepared first, and 1.0 ml of methyltrimethoxysilane was used to prepare 20 nm spherical SiO 2 The particles were surface-modified, and the Pickering emulsion was prepared with the ethyl acetate-water experimental system, and the fixed oil-water ratio was 7ml:5ml, and the W / O type Pickering emulsion with a solid particle concentration of 5% was prepared (such as figure 2 The amount of solid particles remained unchanged, 12 ml of ethyl acetate was added, and a homogeneous suspension was prepared by ultrasonic vibration. The flow ratio of the two systems was 1:1, and the flow ra...

Embodiment 2

[0040] Change the solid particle concentration to 10%, and refer to Example 1 for other conditions. The water-Pickering emulsion system forms a stable slug-like flow pattern in the microchannel, and the droplet length of the dispersed phase gradually decreases with the increase of the flow rate; the water-suspension system cannot form a stable slug-like flow pattern in the microchannel. And there is adhesion phenomenon, the droplet length of the dispersed phase decreases gradually with the increase of the flow rate.

Embodiment 3

[0046] Change the solid particle concentration to 15%, and refer to Example 1 for other conditions. The water-Pickering emulsion system forms a stable slug-like flow pattern in the microchannel, and the droplet length of the dispersed phase gradually decreases with the increase of the flow rate; the water-suspension system cannot form a stable slug-like flow pattern in the microchannel. And there is adhesion phenomenon, the droplet length of the dispersed phase decreases gradually with the increase of the flow rate.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com