Complete recovering technique for hydrochloride in industrial gas

An industrial gas and hydrogen chloride technology, which is applied in the direction of chlorine/hydrogen chloride, chlorine/hydrogen chloride purification, chemical instruments and methods, etc., can solve the problems of vinyl chloride refining quality, discontinuous operation of alkali washing tower, etc., and achieve small footprint, The effect of large operation flexibility and simplified process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] The present invention is preferably described below in conjunction with the examples, but the protection scope of the present invention is not limited thereto.

[0035] A kind of full recovery process of hydrogen chloride in industrial gas, comprises following sequential steps:

[0036] (1) After the industrial gas containing hydrogen chloride enters from the combined absorption tower bottom, after absorbing from the water from the top, the industrial gas with a concentration of more than 99% is obtained at the top of the tower, and concentrated hydrochloric acid is obtained at the bottom of the tower;

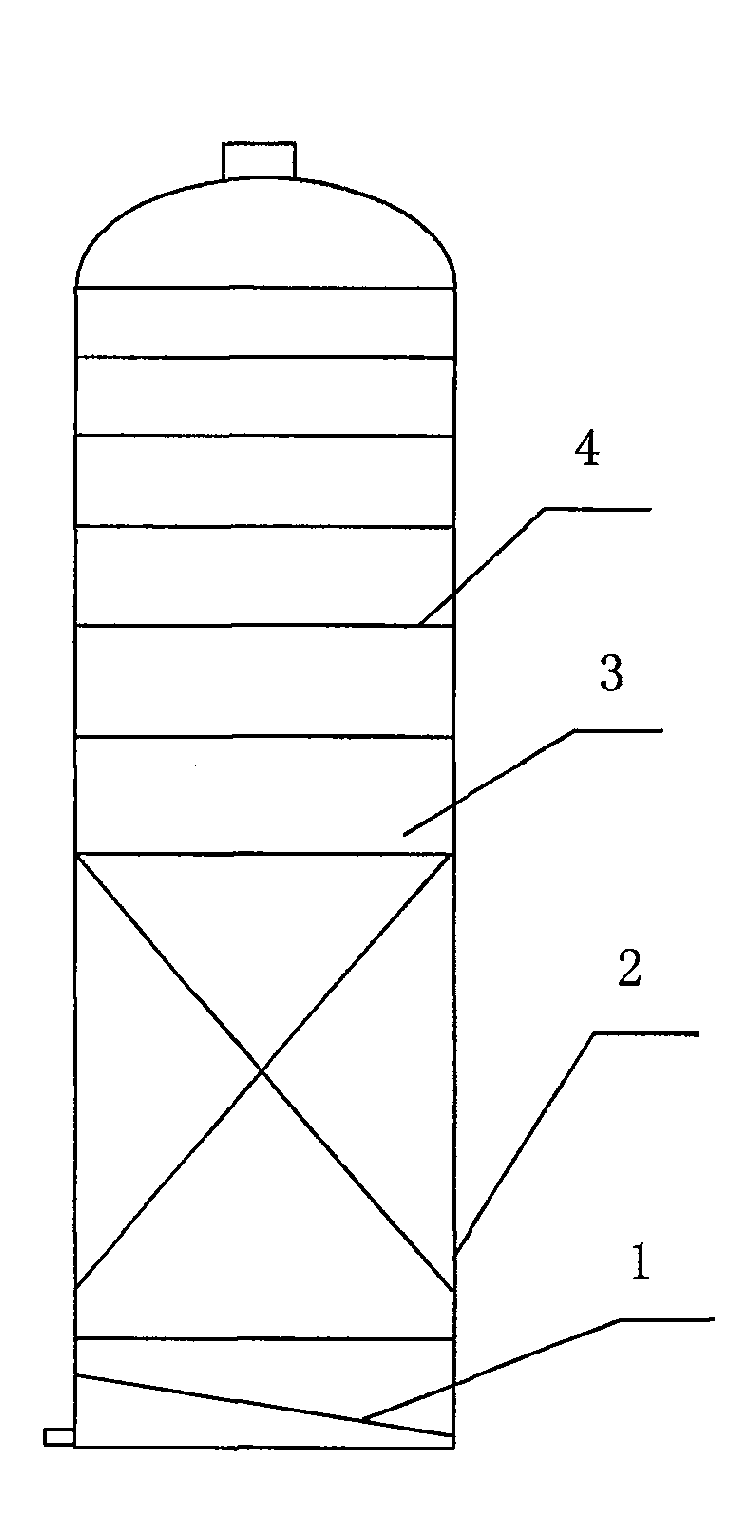

[0037] refer to figure 1 , the combined absorption tower comprises from bottom to top successively: gas distribution area 1, packing absorption area 2, gas-liquid separation area 3, tray absorption area 4, gas distribution area 1 bottom is provided with gas inlet, tray absorption area 4 The upper part is equipped with a water inlet, and the industrial gas and water con...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com