Zero-loss internal recycle type gas purifying method and device

A technology of gas purification and internal circulation, which is applied to chemical instruments and methods, separation methods, and separation of dispersed particles. It can solve the problems of short switching time, high gas consumption, and large regeneration gas consumption. The effect of simple method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

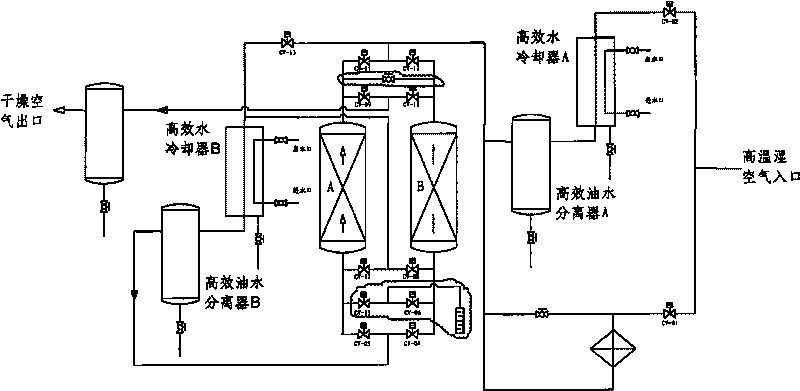

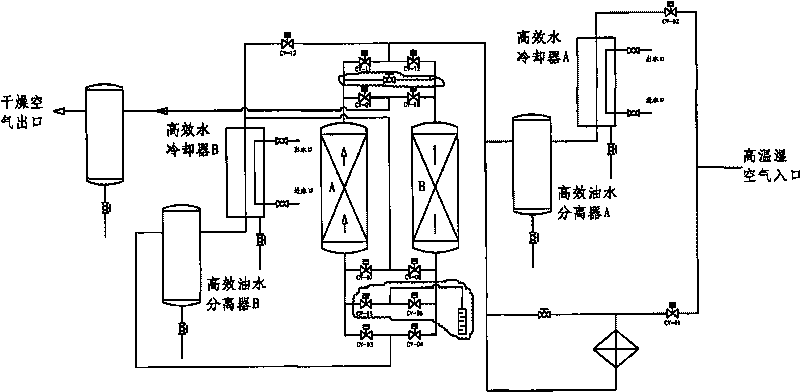

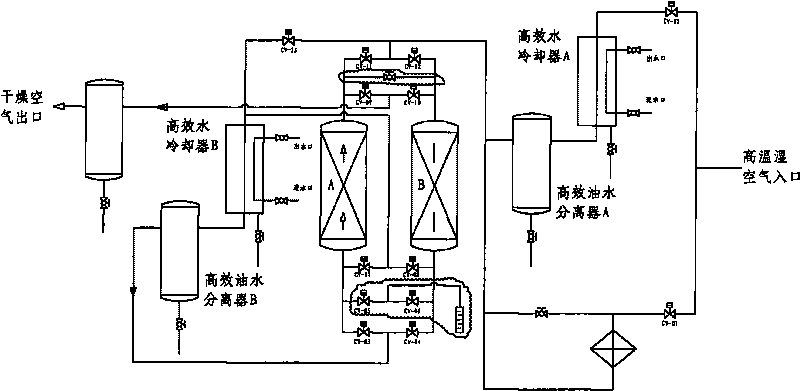

[0015] The present invention will be described in detail below in conjunction with the accompanying drawings: the zero-loss internal circulation gas purification method of the present invention mainly uses the high-temperature gas regeneration adsorption drying tower discharged from the compressor or heated by the low-temperature gas. In one cycle, one of the adsorption towers A is used as a drying tower, and the other adsorption tower B is used as a regeneration tower, and after one cycle is over, the next cycle is repeated after switching, and the cycle is carried out. The method includes the following two stages:

[0016] The first stage is the drying-heating regeneration stage. The high-temperature gas enters the regeneration tower——B tower to heat the adsorbent, then enters a post-installed water cooler to lower the temperature, and then flows into a post-installed oil-water separator to separate the exchange gas. After carrying a small amount of liquid, the gas enters the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com