Spiral belt piece type multi-gas field drum screen grain cleaning machine

A cleaning device, multi-gas field technology, applied in the direction of sieve, separation of solids from solids by air flow, solids separation, etc., can solve the problems of large space occupation, large power loss, complex structure, etc., and achieve work efficiency High, low power loss, simple structure effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

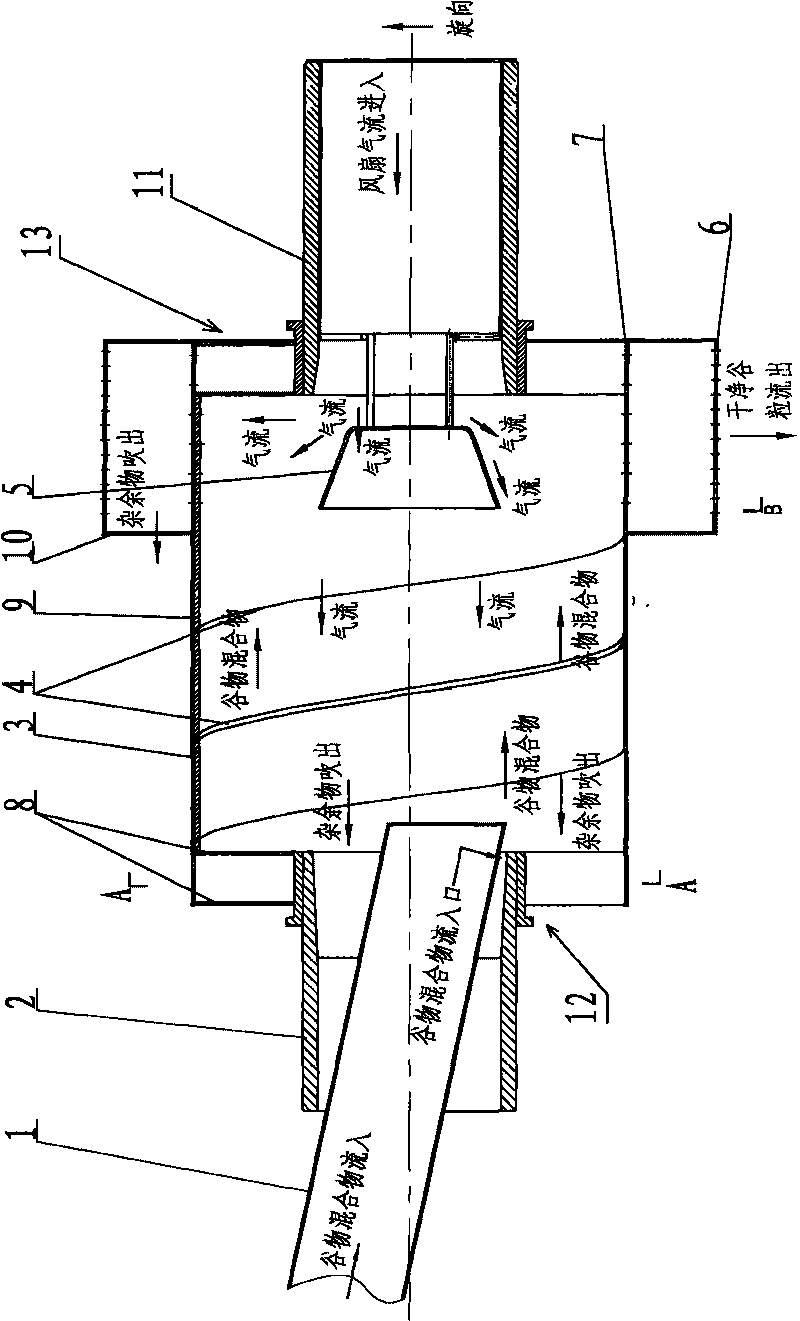

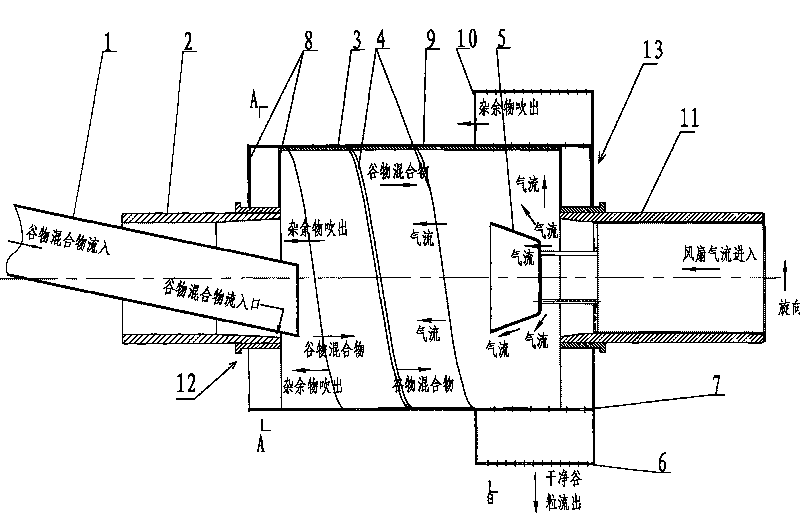

[0025] like figure 1 and figure 2 As shown, the grain cleaning device of the spiral belt sheet type multi-air field drum sieve includes a hollow cylindrical drum 3, and hollow shafts 2, 11 are respectively installed at both ends; and the cylindrical drum 3 and the hollow shaft 2, 11 is concentric, one end of the cylindrical drum 3 is the feed end 12 and the other end is the airflow inlet end 13;

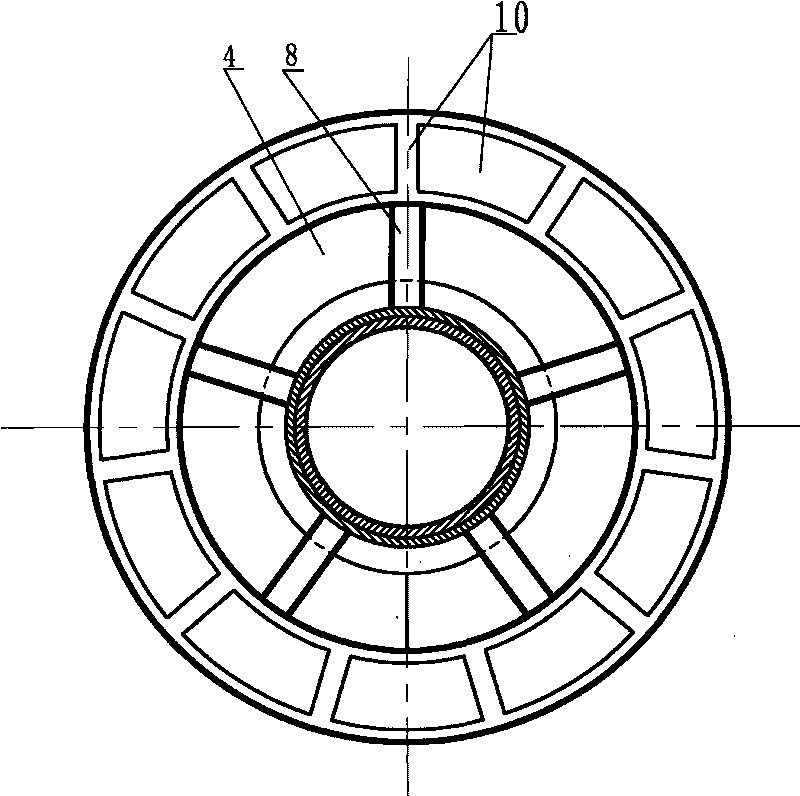

[0026] The inner spiral strip 4 is arranged continuously along the inner circumference and the axial direction of the cylinder drum 3; the drum body between the end of the inner spiral strip 4 and the airflow inlet port 13 of the cylinder drum is provided with a first-stage cylindrical screen 7, in which The first-stage cylindrical sieve 7 is equipped with a coaxial secondary cylindrical sieve 6 with a certain radial space with the first-stage cylindrical sieve on the outer periphery; the feeding end 12 of the hollow cylindrical drum 3 is provided with a The discharge port is loca...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com