Method for distributing grinding point group of disk type metal polishing sheet for grinding long fiber material

A layout method and grinding point technology, applied in the direction of abrasives, metal processing equipment, bonded grinding wheels, etc., can solve the problems of suppliers' procurement and supply channels not being timely and smooth, unfavorable for survival and development, and pressure on production costs. Achieve the effect of improving the bending strength and chip removal function, grinding the surface better, and improving the bending strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

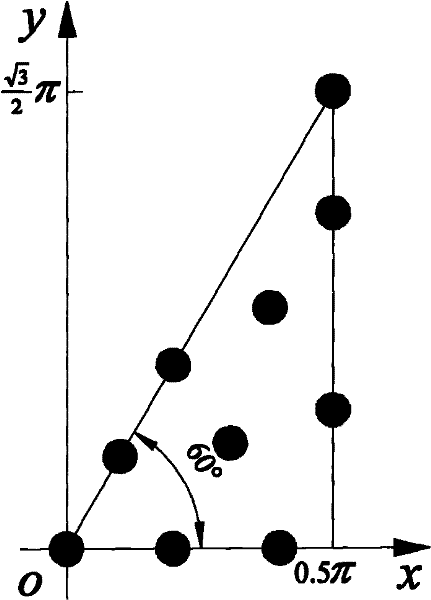

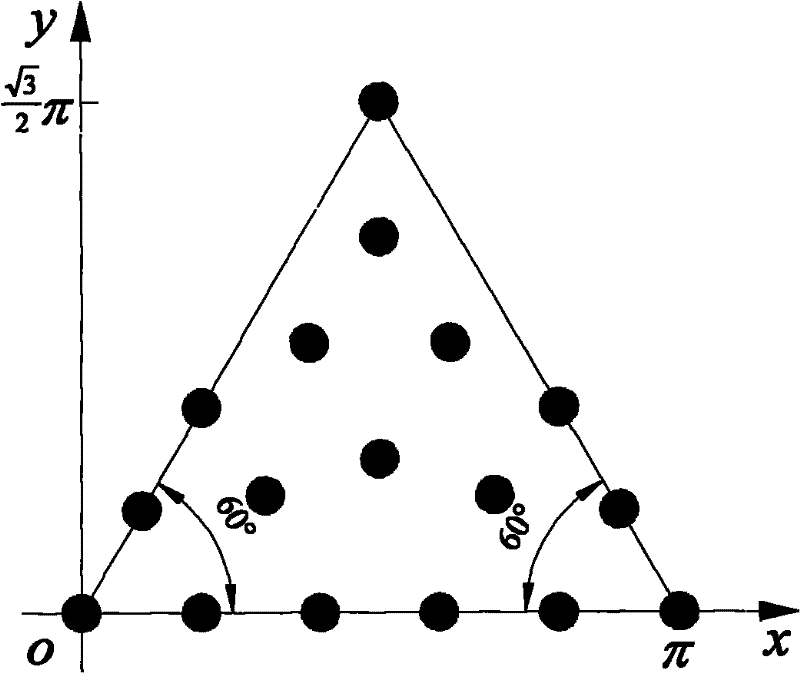

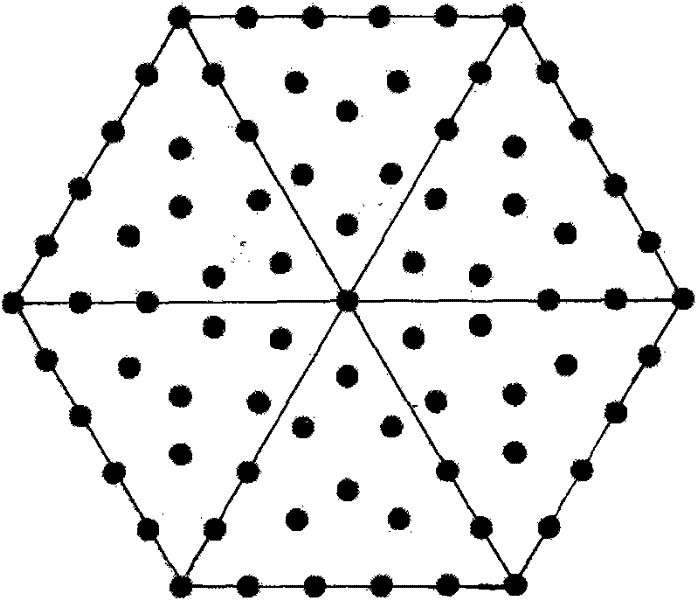

[0033] 1) The value of the parent point coordinates

[0034] Design the basic unit that determines the extended shape of the grinding disc. The entire regular hexagon is divided into 12 right triangles with an acute angle of 30°. Use the Cartesian coordinate system for drawing, and set the center point of the hexagon as the coordinate origin, then the hexagon is symmetrical about the origin. An equilateral triangle is formed by one side and the center of the hexagon, and there are 10 points in the first right triangle in the first quadrant, and these 10 points are the "parent points". The layout of the entire grinding surface is converted into the layout of the parent point, and the requirements for the basic unit are also converted into the requirements of the parent point.

[0035] In order to minimize the coincidence of the grinding tracks of each shop and avoid the formation of uneven grinding and groove marks, according to the grinding theory, the coordinates of the par...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com