Automatic in-mould edge gate cutting injection mould

A technology for automatic cutting and injection molding, which is applied to the field of automatic cutting of injection molds and plastic injection molds at the inner gate of the mold. , the effect of prolonging the service life and reducing the manufacturing cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

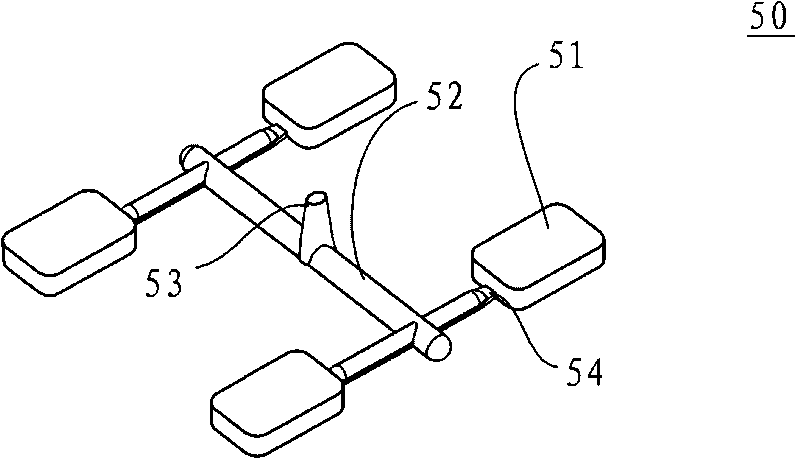

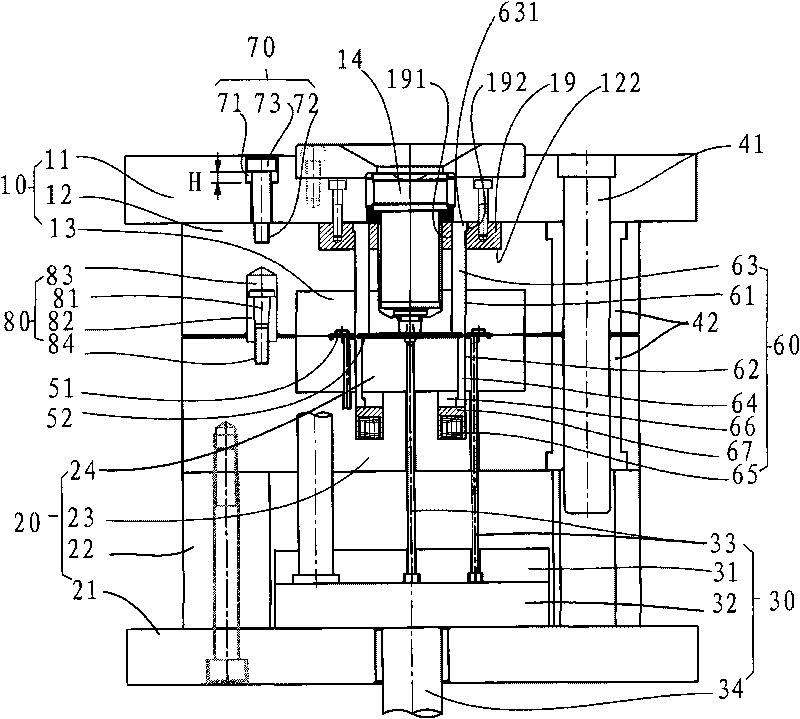

[0046] see image 3 A kind of mold inner side gate automatic cut-off injection mold of preferred embodiment of the present invention, comprises the fixed mold 10 that is made of fixed mold fixed plate 11, fixed template 12, fixed mold core 13, is made of movable mold fixed plate 21, pad iron 22. The movable mold 20 composed of the movable template 23 and the movable mold core 24, the ejector mechanism 30 composed of the upper ejector plate 31, the lower ejector plate 32, a plurality of ejector pins 33 and the ejector rod 34 of the injection molding machine, The guide post 41 and the guide sleeve 42 connecting the movable mold 20 and the fixed mold 30, and the gate cutting device 60, wherein the gate cutting device 60 includes a gate located at the side gate of the injection molded part, which passes through the fixed mold core 13 and the fixed template 12 A plurality of reset rod sliding holes 61, opposite to the plurality of reset rod sliding holes 61, a plurality of cutter s...

Embodiment 2

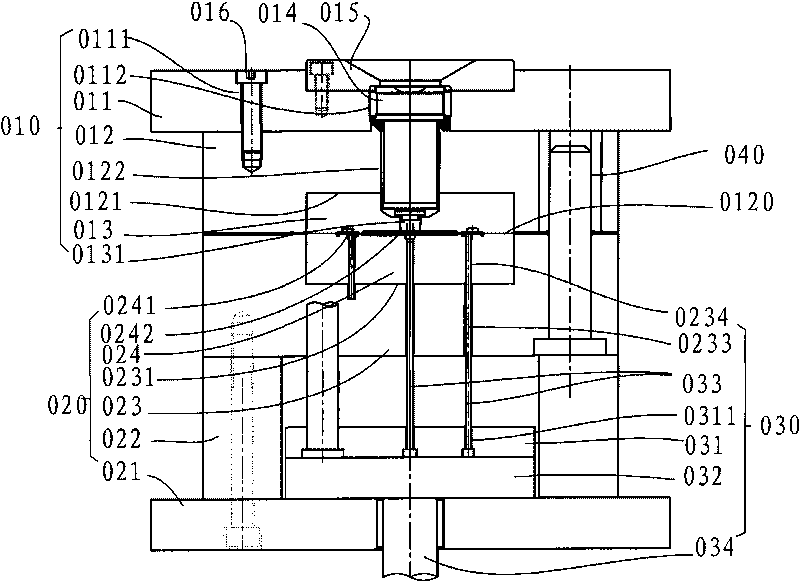

[0052] see Figure 4 Shown is another preferred embodiment of the injection mold with automatic cut-off of the gate inside the mold of the present invention, including a fixed mold composed of a fixed mold fixed plate 11', a fixed mold plate 12', and a fixed mold core 13' fixed sequentially. , the movable mold composed of the movable mold fixed plate 21, the pad iron 22, the movable template 23' and the movable mold core 24', the ejector formed by the upper ejector plate 31, the lower ejector plate 32 and a plurality of ejector pins 33 Mechanism, a guide post 41 and a guide sleeve 42 connecting the movable mold and the fixed mold, and a gate cutting device, wherein the gate cutting device includes a gate located at the side gate of the injection molded part, passing through the movable mold core 24' and the movable template 23' A plurality of reset rod sliding holes 61', opposite to the plurality of reset rod sliding holes 61', a plurality of cutter sliding holes 62' passing t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com