Method and equipment for three-dimensional shaped thermal transfer

A thermal transfer and thermal transfer film technology, applied in transfer printing, rotary printing machine, printing and other directions, can solve the problems of inability to transfer, not waterproof, poor alignment accuracy, unenvironmental pollution, etc., to achieve product appearance and quality. The effect of quality improvement, effect and efficiency improvement, and high control precision

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

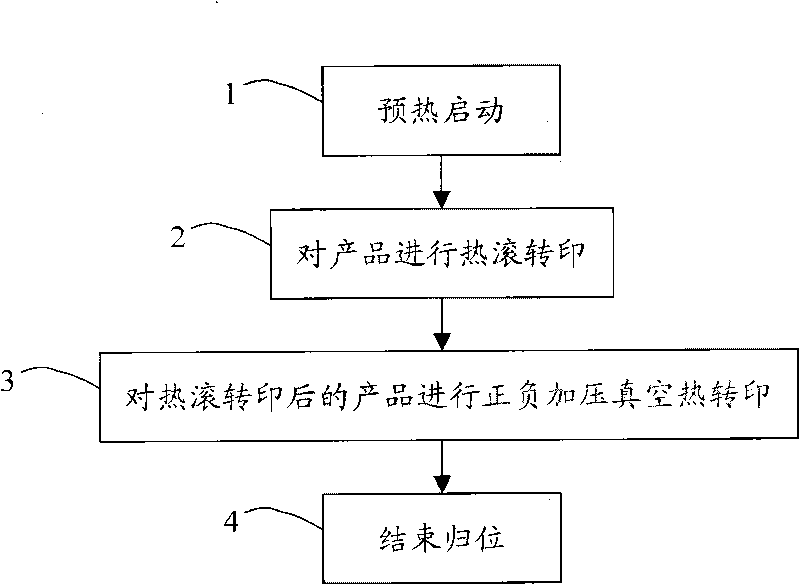

[0052] Such as figure 1 As shown, the three-dimensional special-shaped thermal transfer method of the first embodiment of the present invention includes the steps:

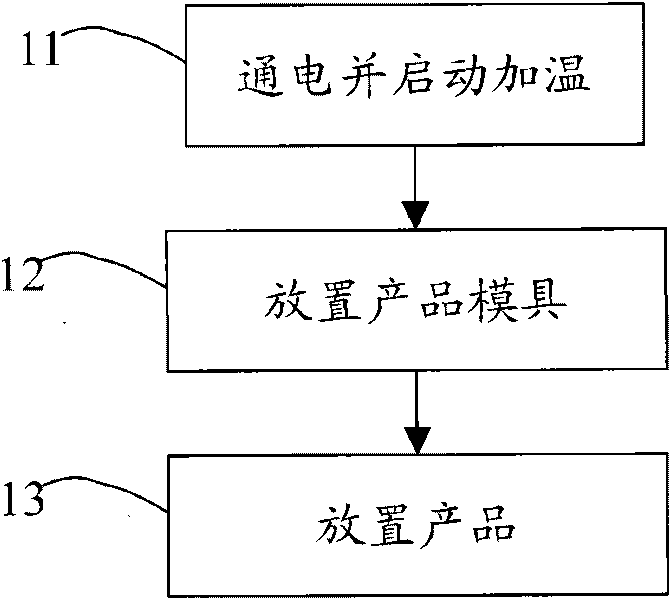

[0053] 1. Preheating start; this step preheats the heating components and provides temperature for the following transfer steps.

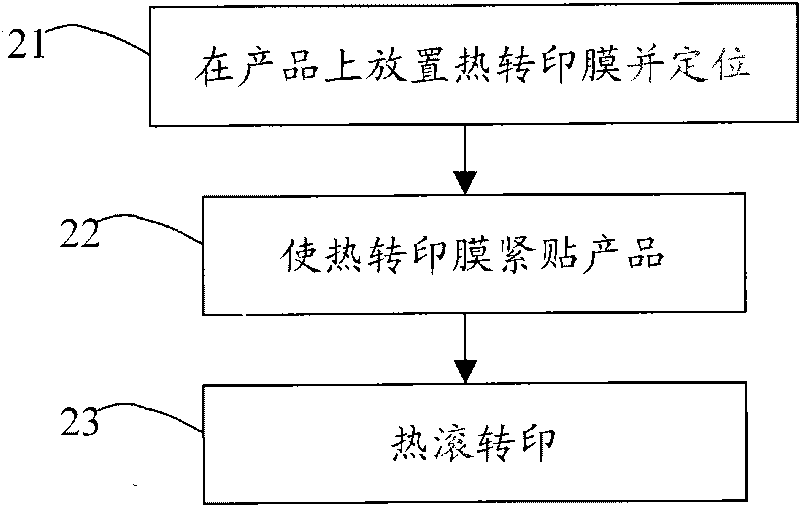

[0054] 2. Perform thermal roll transfer on the product; this step uses heating to make the thermal transfer film adhere to the product, but because the surface of the product may be irregular, the thermal transfer film may not adhere firmly, so proceed to the next step.

[0055] 3. Perform positive and negative pressure vacuum heat transfer on the product after the heat transfer transfer; this step uses external force to make the heat transfer film positive and negative pressure close to the surface of the product to strengthen the bond between the heat transfer film and the product And complete the transfer.

[0056] 4. End homing. This step will end the transfer process.

[0057] The above-m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com