Polymer antistatic and conductive composite material and preparation method thereof

A technology of conductive composite materials and polymers, applied in the direction of conductive materials dispersed in non-conductive inorganic materials, chemical instruments and methods, and other chemical processes, to achieve the effect of simple preparation process and good volume conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1~10

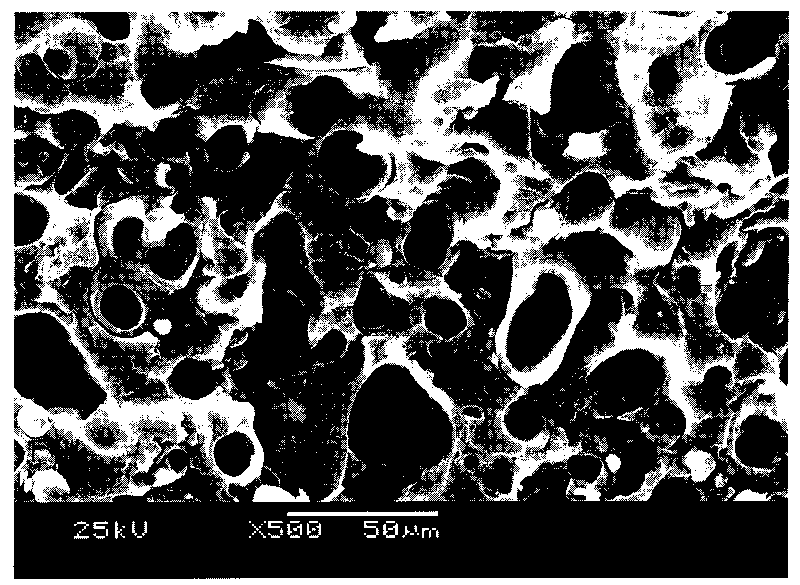

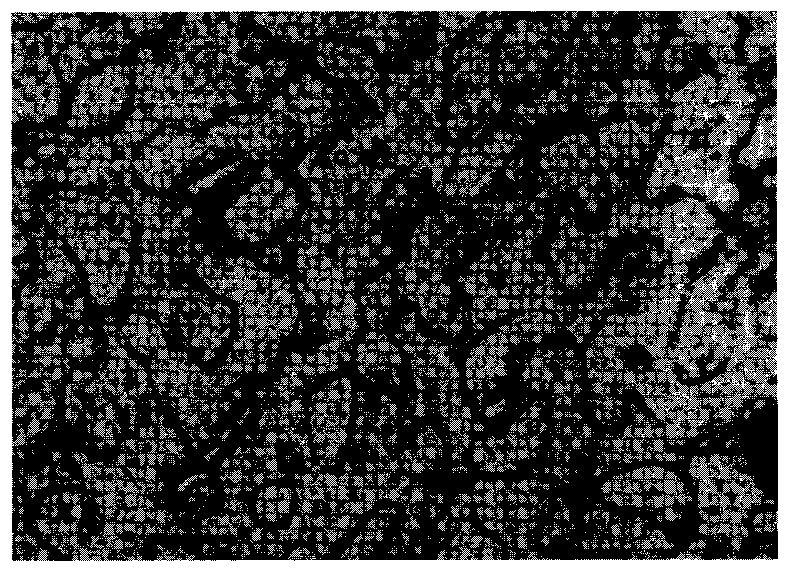

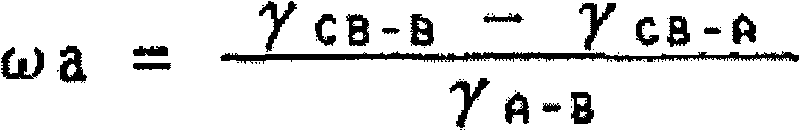

[0022] Examples 1 to 10: polymer-based antistatic and conductive composite materials were prepared according to the following specific steps and performance tests were performed. Preparation process: at a processing temperature of 130°C, the vinyl copolymer and the conductive filler are mixed and processed for 10 minutes to make a masterbatch. Then, at a processing temperature of 180°C, the polypropylene, polymethyl methacrylate and the prepared masterbatch were put into an internal mixer for mixing and processing for 6 minutes in proportion to obtain a polymer-based antistatic and conductive composite material.

[0023] Hot press at 180°C for 15 minutes in a flat vulcanizer, with a pressure of 15Mpa, to obtain a test sample of 35×12×1.4mm, and test the electrical properties after standing for 6 hours. The low resistance is tested with a smart multimeter (3146A, ESCORT). The high resistance is measured with a ZC36 ultra-high resistance tester. When measuring light transmitta...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com