Rotatable sputtering cathode device for film coating

A cathode and sputtering technology, which is applied in the field of rotary sputtering cathode devices for coating, can solve the problems of reducing the utilization rate of the target material, troublesome, destroying the uniformity of the coating layer, etc., so as to avoid the formation of the sputtered oxide layer and improve the uniformity , the effect of improving utilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

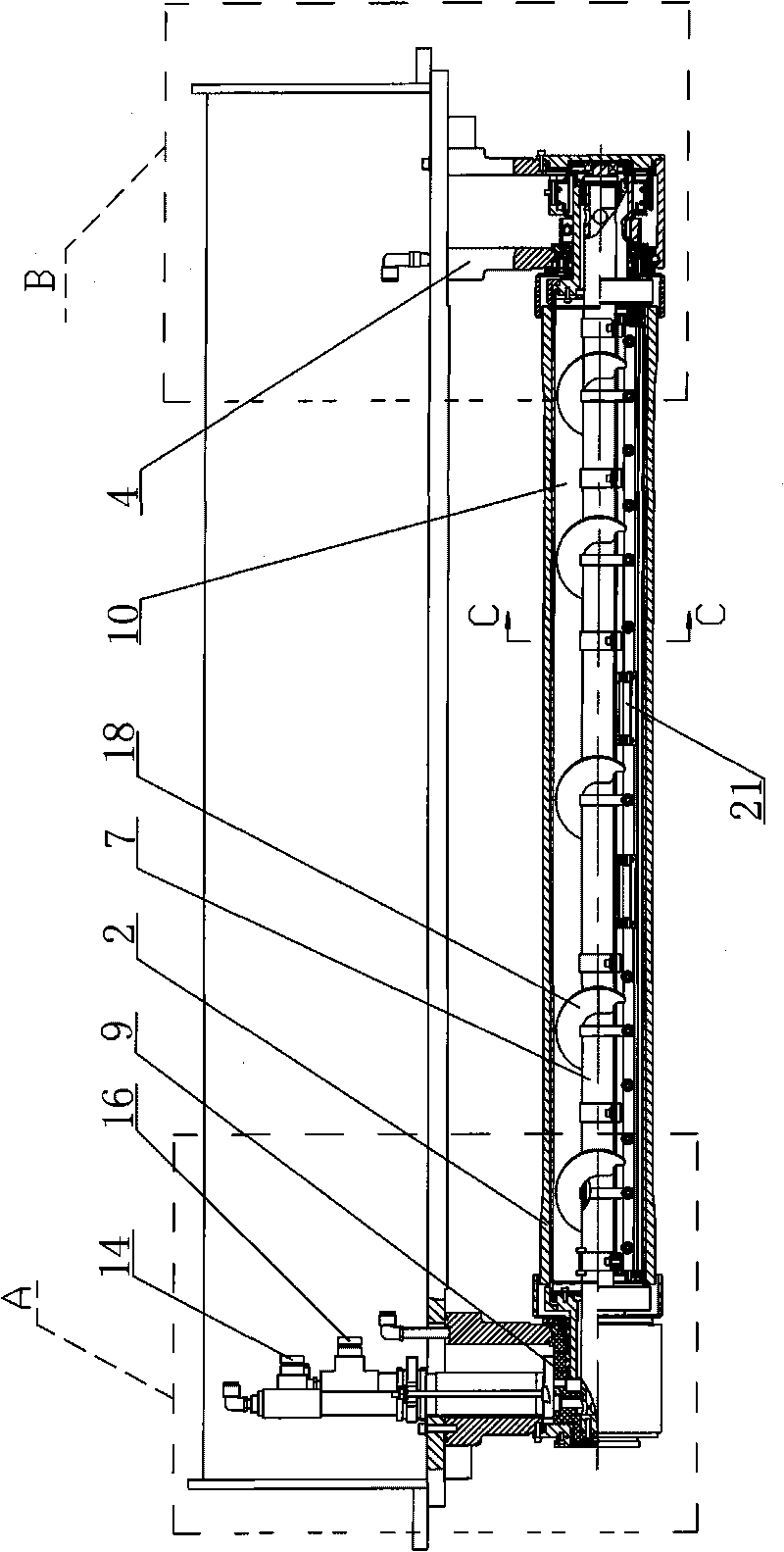

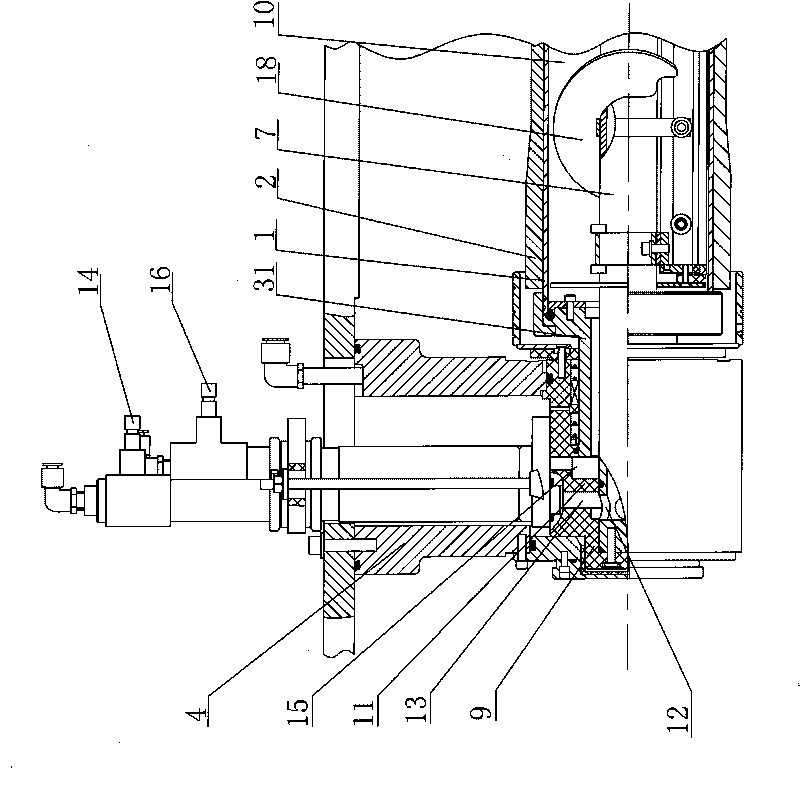

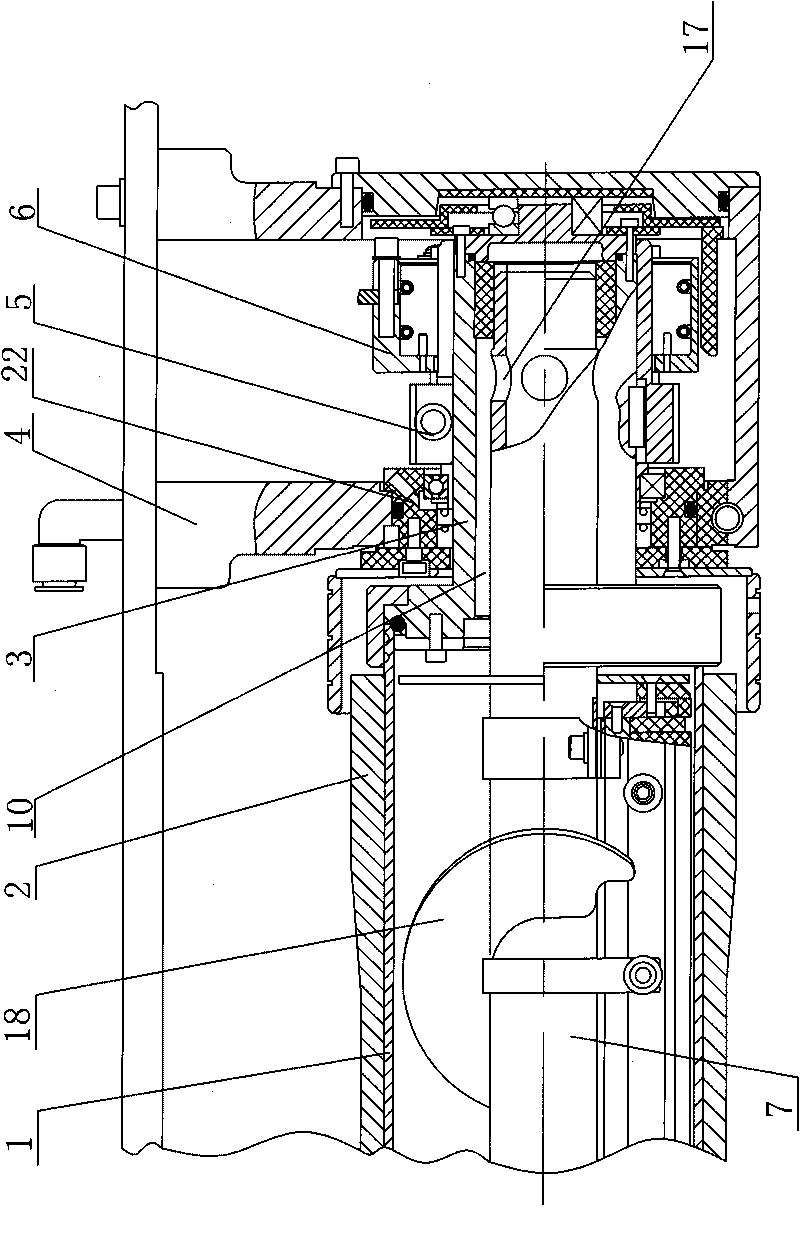

[0015] The technical solution of the present invention, its working principle and advantages will be further described below in conjunction with the accompanying drawings and specific embodiments.

[0016] like figure 1 , figure 2 , image 3 As shown, the rotary sputtering cathode device for coating includes: a tubular target 2 installed on the cathode tube 1, and the two ends of the cathode tube 1 are respectively connected with a supporting base 3 and 31, and one of the supporting bases 3 passes through The insulator 22 and the bearing are movable and supported on the frame 4 in an insulated manner. The supporting base 3 is provided with a drive wheel 5 and a brush 6, and the power is transmitted to the cathode tube 1 through the brush 6 and the supporting base 3; The inside of the tube 1 is also insulated and supported with a central support tube 7, and the bottom of the central support tube 7 is provided with a magnetic core element 8, see Figure 4 As shown, the magne...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com