Sealed structure of rolling piston compressor or engine

A technology of rolling piston and sealing structure, which is applied to the sealing device of the engine, machine/engine, and engine components, etc., can solve the problems of poor sealing performance of the rolling piston mechanism, increase the leakage of compressed gas, and the gap cannot be automatically compensated. Good performance, improved efficiency, flexible and convenient use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

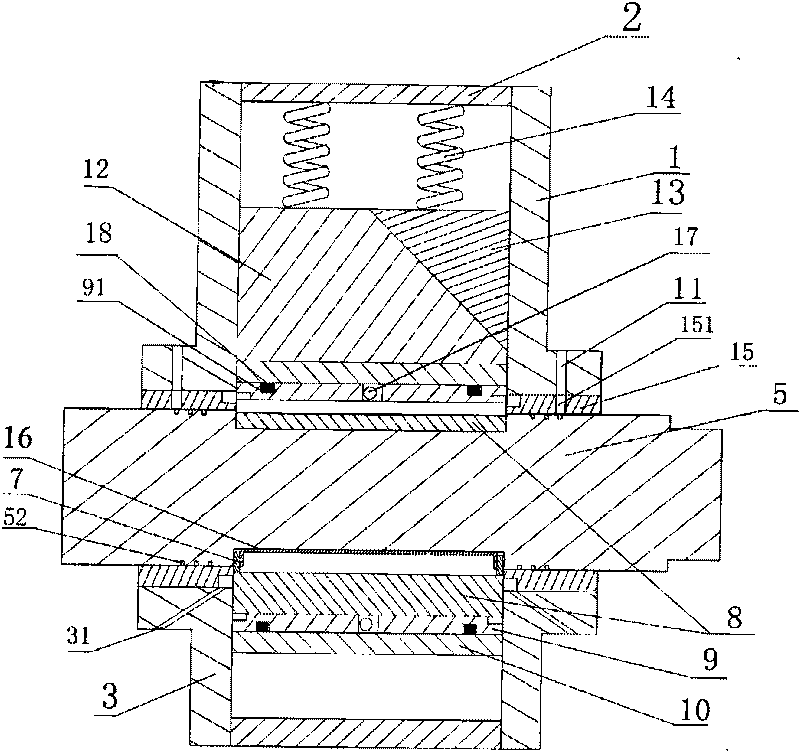

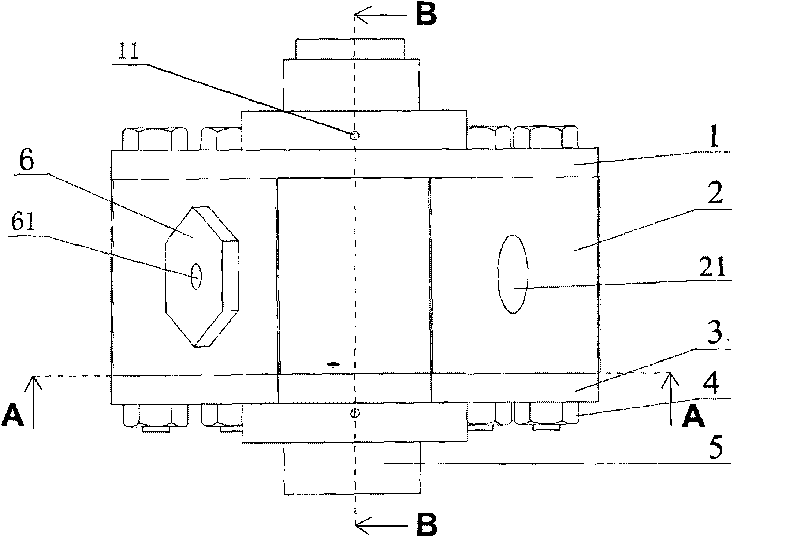

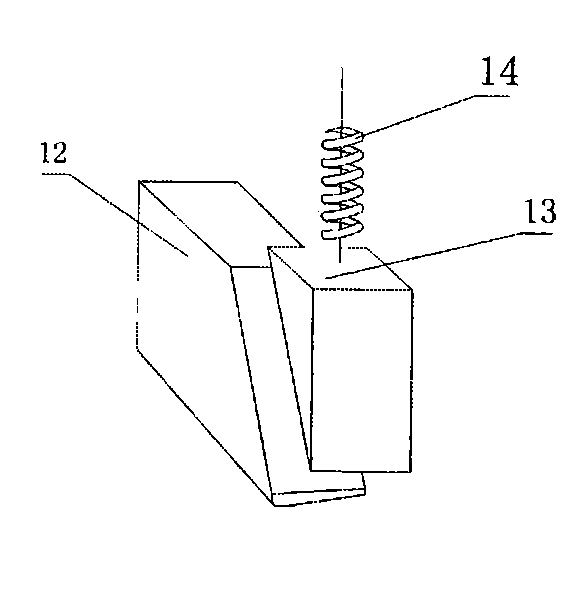

[0020] see Figure 1 to Figure 6 , the sealing structure of the rolling piston compressor or the engine comprises a cylinder block 2, a front cylinder cover 1, a rear cylinder cover 3, a slider, a sliding eccentric 8 is arranged on the power main shaft 5, and a rolling sleeve 10 is arranged outside the sliding eccentric 8 , a radial chute 81 is provided on the sliding eccentric wheel 8, and the radial chute 81 and the sliding surface 51 on both sides of the power main shaft 5 are radially slidable; There is a gap, and an oil guide structure is provided to connect the above gap with the hydraulic device. An eccentric wheel bearing 9 is arranged between the sliding eccentric wheel 8 and the roller sleeve 10 . There are two eccentric wheel bearings 9 with butterfly springs 17 in the middle, and sealing rings 18 are provided on the outer rings of the two eccentric wheel bearings 9 to form a rolling piston end face seal. The oil guide structure is: one end or both ends of the pow...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com