Double-clutch transmission mechanism

A dual clutch and transmission technology, applied in mechanical equipment, gear transmission, belt/chain/gear, etc., can solve the problems of complex power transmission structure, difficult processing, high production cost, etc., achieve high integration and reduce production cost , the effect of saving energy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

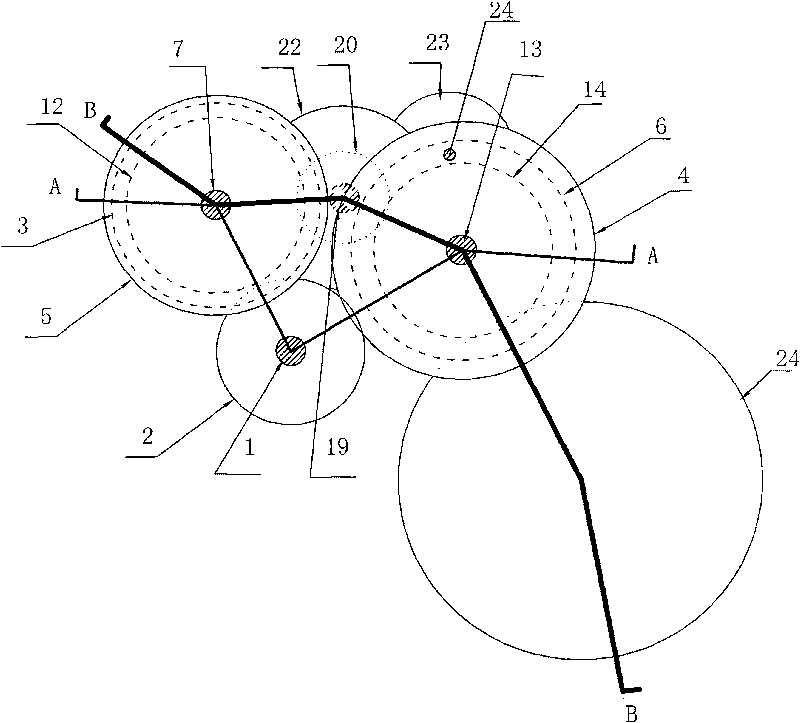

[0019] Such as figure 1 The shown first embodiment of the dual-clutch five-speed transmission of the present invention includes an engine input shaft 1, a first layshaft 7, a second layshaft 13, and an intermediate shaft 19 arranged parallel to each other and rotatable around its own axis, The axes of the engine input shaft 1 and the intermediate shaft 19 are located in the middle of the axes of the two layshafts.

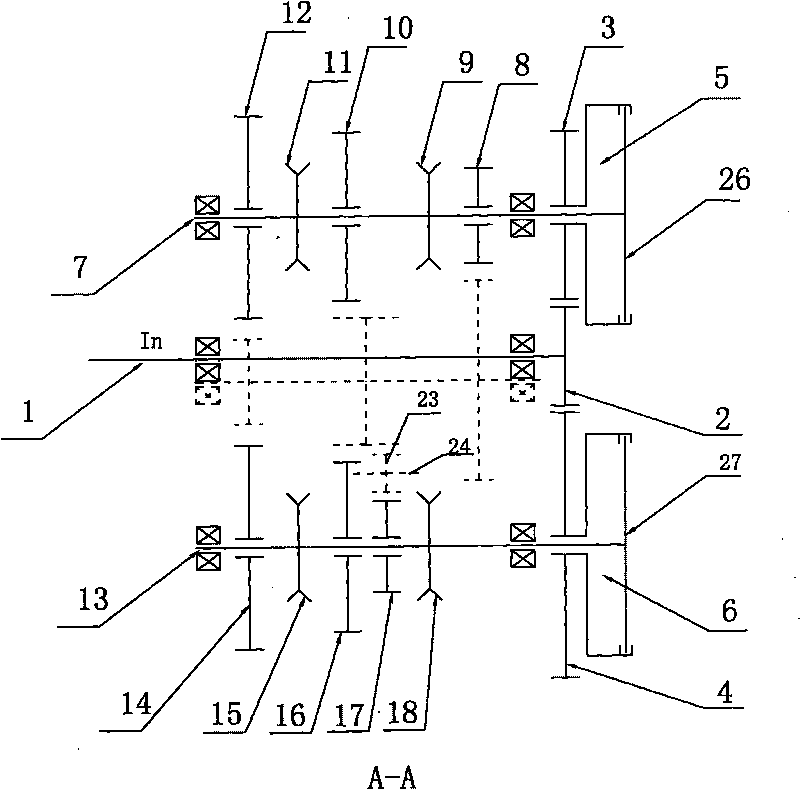

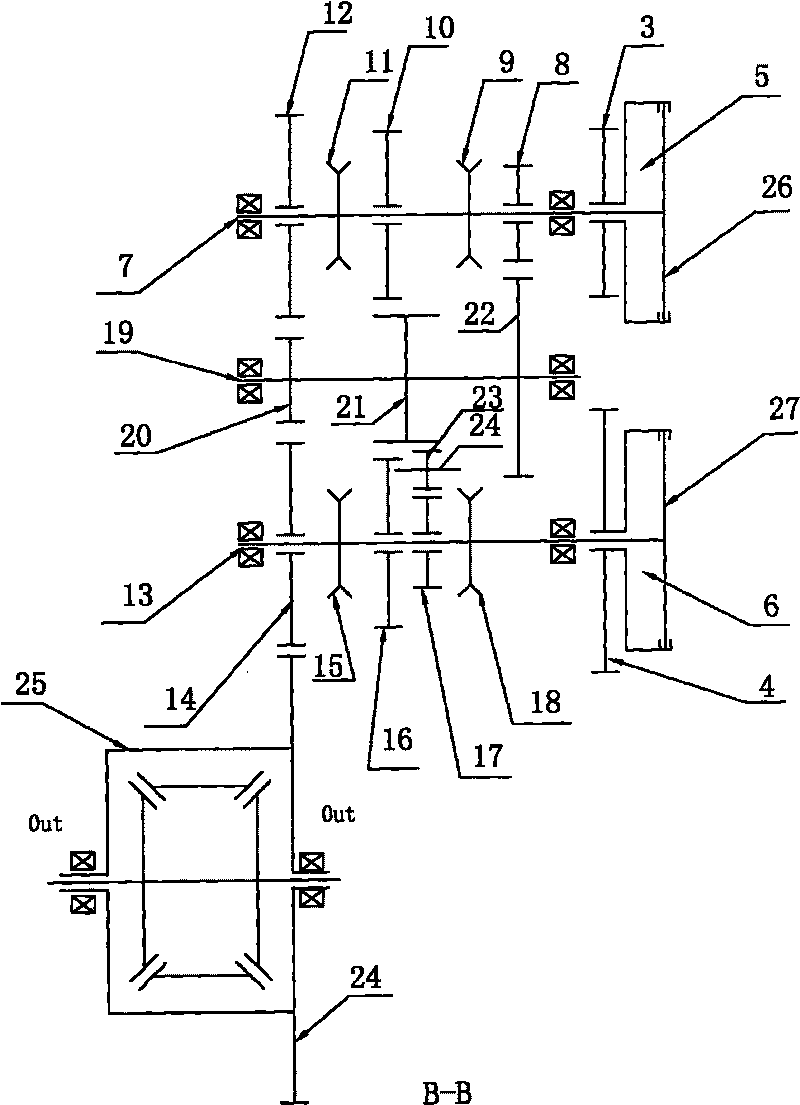

[0020] Such as figure 2 or image 3 As shown, the right end of the input shaft 1 of the engine is equipped with an input shaft gear 2, and the input shaft gear 2 meshes with an odd-numbered clutch driving gear 3 and an even-numbered clutch driving gear 4 with different transmission ratios;

[0021] The odd-numbered gear clutch 5 and the even-numbered gear clutch 6 are respectively fixedly installed on the right ends of the first countershaft 7 and the second countershaft 13 through the internal odd-numbered friction plates 26 or even-numbered friction plates 27,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com