LED (Liquid Emitting Diode) white light bulb and production method thereof

A manufacturing method and technology for LED chips, which are applied in the directions of light sources, electric light sources, point light sources, etc., can solve the problems of poor light transmittance, difficult to solve the problem of chip heat dissipation, and aging of packaging materials.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

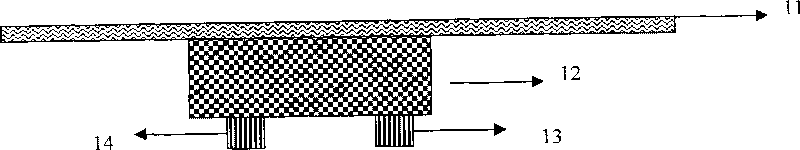

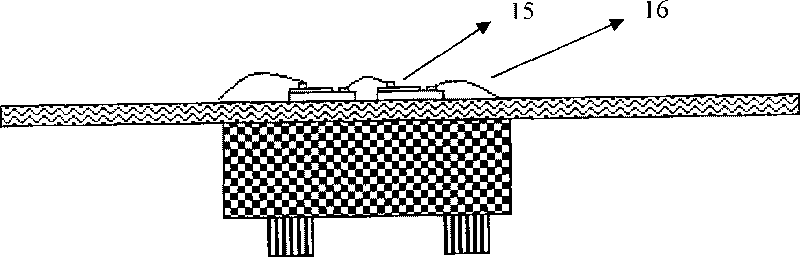

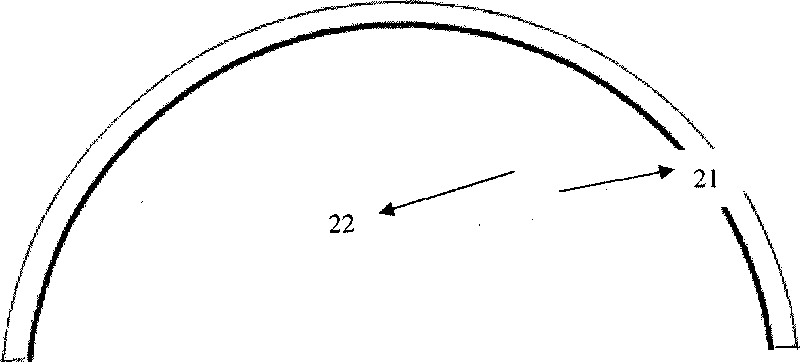

[0025] Refer below figure 1 , figure 2 , image 3 , Figure 4 , specifically describe the embodiments of the present invention. The LED white light bulb comprises: a heat dissipation substrate 11, an LED chip 15, a glass cover 21, an insulating base 12, electrodes 13, 14, the LED chip 15 is fixed on the heat dissipation substrate 11, and the glass cover 21 is bonded to the heat dissipation substrate 11 The light from the LED chip 21 passes through the glass cover 21 , and phosphor powder is coated inside the glass cover 21 , the other side of the heat dissipation substrate 11 is connected to the insulating base 12 , and the insulating base is connected to the lead electrodes 13 and 14 .

[0026] The glass cover 21 is hemispherical.

[0027] A method for manufacturing an LED white light bulb, comprising:

[0028] (1) On one side of the thermally conductive substrate 11, a printed circuit for LED chip connection is prepared, and the part other than the printed circuit is m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com