Manufacture process of LED (Light Emitting Diode) photoelectrical glass

A photoelectric glass and manufacturing process technology, which is applied in the field of LED photoelectric glass manufacturing technology, can solve the problems of indoor and outdoor viewing functions and high maintenance costs, affecting lighting, etc., to ensure effective connection, ensure service life, reduce The effect of maintenance costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

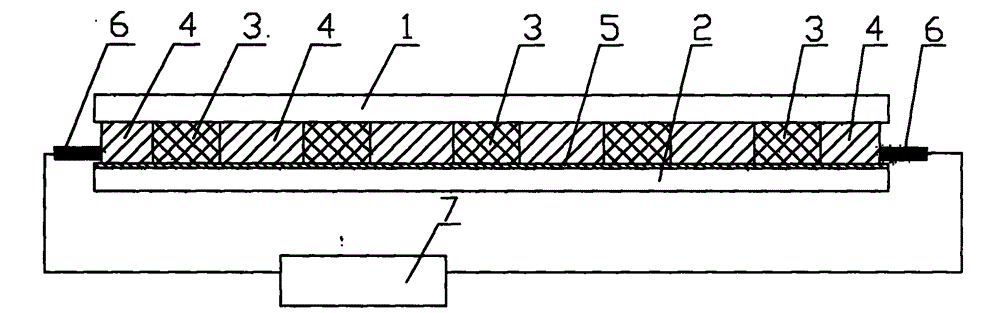

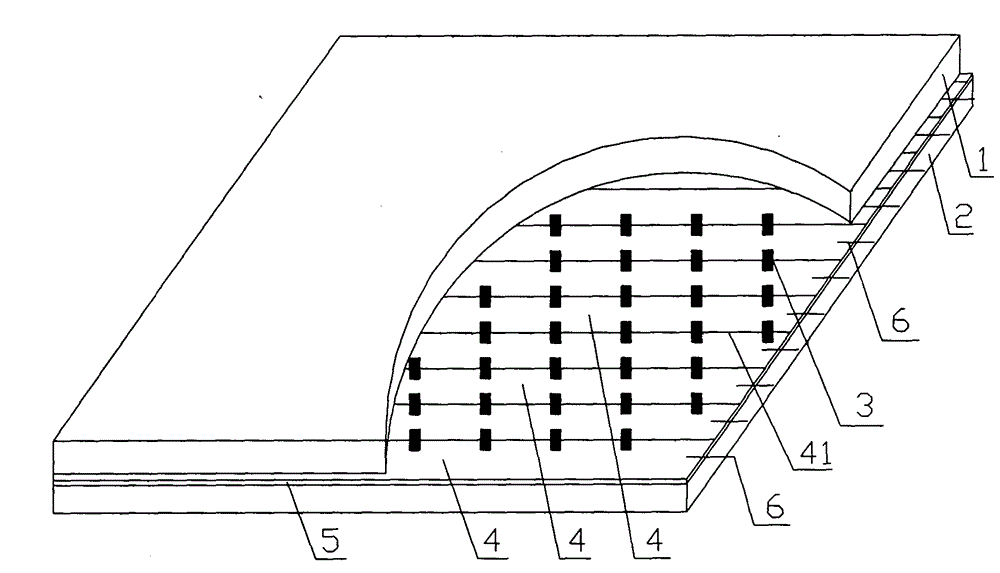

[0040] The manufacturing process of the LED photoelectric glass of the present invention will be described in detail below with reference to the accompanying drawings.

[0041] Such as figure 1 with figure 2 As shown, the present invention discloses a kind of LED photoelectric glass, which includes a glass substrate, packaging glass and light-emitting diodes. The glass substrate is provided with a conductive layer, and the conductive layer is etched to form the two poles of the light-emitting diode. The glass substrate and The encapsulating glass is encapsulated by an adhesive layer.

[0042] The conductive layer is made of SnO 2 Material. The conductive layer extends to the edge of the glass substrate and is connected with metal pins, and the metal pins are connected with external circuit control devices. The adhesive layer adopts PVB film, EVA film or SGP film. Metal pins are silver-plated metal.

[0043] The present invention also provides a manufacturing process of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com