Heat-absorbing body rotary air heat absorber for solar thermal power station

A solar heat and heat sink technology, applied in solar thermal power generation, solar collectors, solar collectors in specific environments, etc. Heat transfer efficiency, simple structure effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

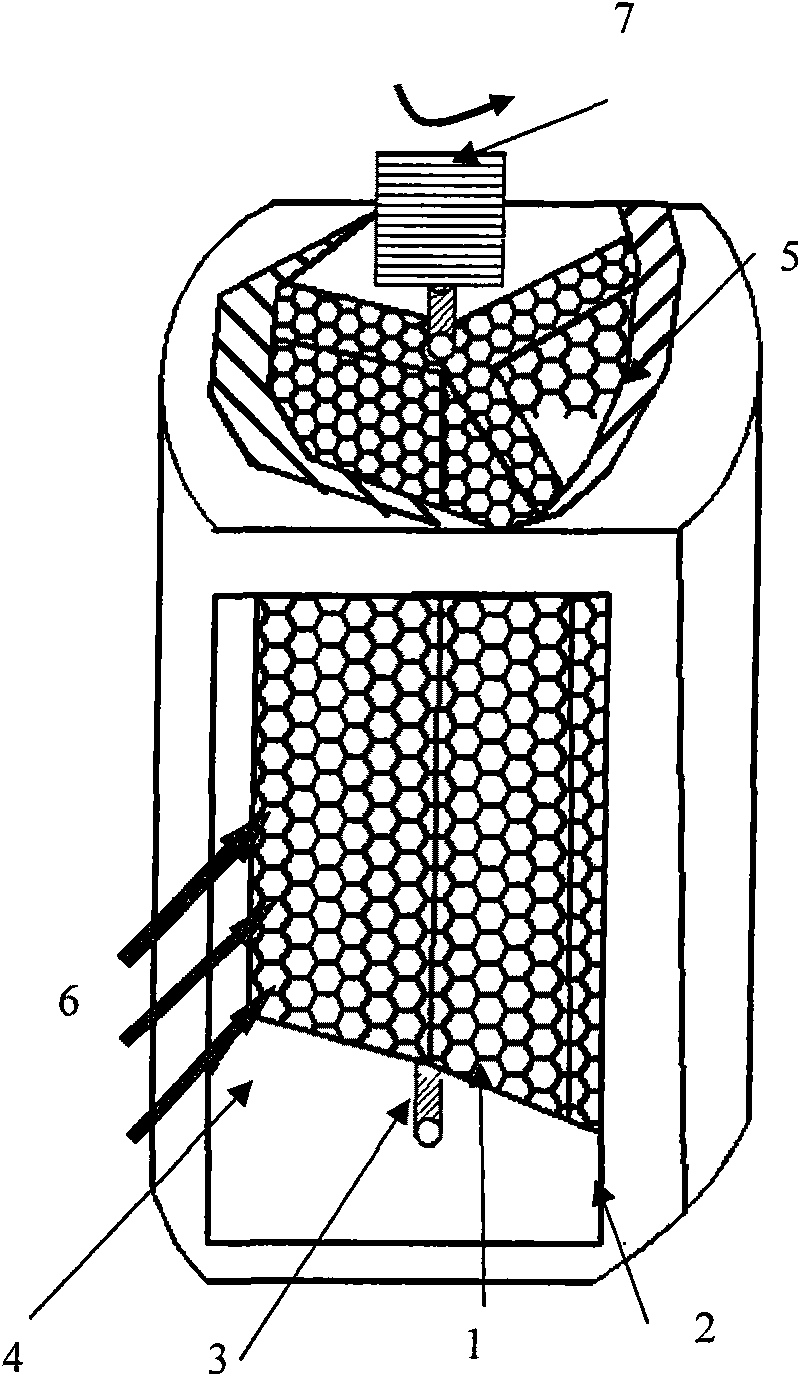

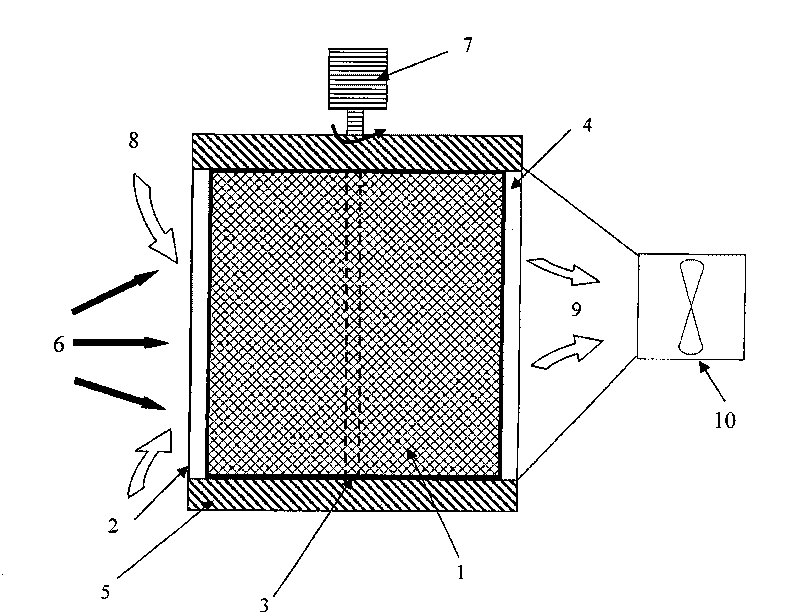

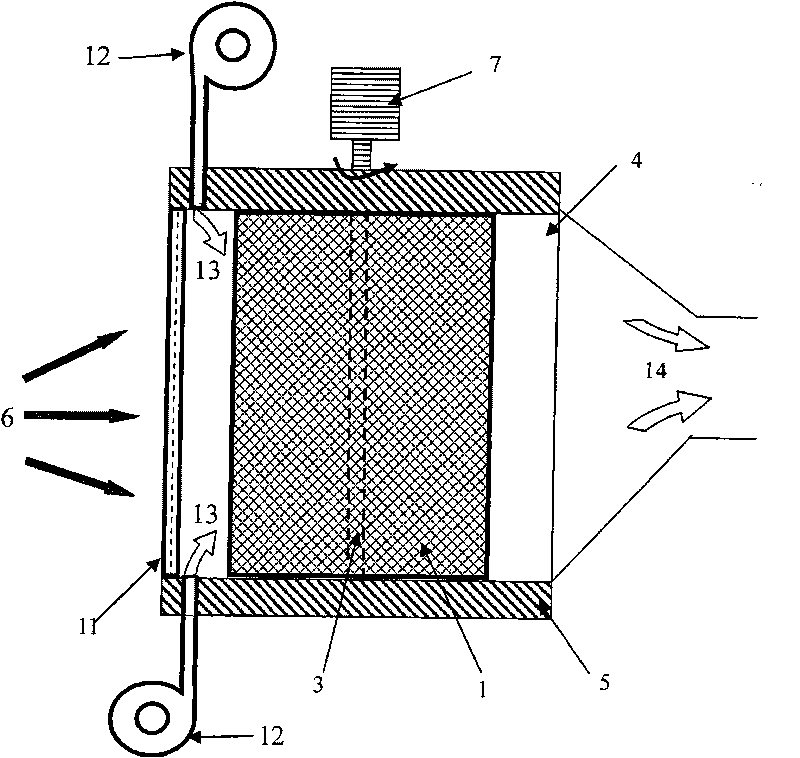

[0015] figure 1 Shown is the solar thermal power station of the present invention with a rotating air heat absorber with heat absorbing body. The heat absorber is composed of a silicon carbide foam ceramic heat absorber 1, a radiation input window 2, a rotating shaft 3, an air cavity 4 and an insulation layer 5. The silicon carbide foam ceramic heat absorber 1 can be composed of three or more silicon carbide The foam ceramic plate is integrally formed and has a high radiation absorption rate. The selection of the foam ceramic pore size and pore structure is determined by the air flow field parameters and the distribution of the concentrated radiation energy flow. The radiation input window 2 is a rectangle or other geometric shapes, and its function is to transmit the concentrated radiation energy flow 6 to the greatest extent. The rotating shaft 3 is a dense silicon carbide ceramic rod body, which is integrally sintered with the silicon carbide foam ceramic heat absorber 1. ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com