Gunpowder ignition temperature measuring device

A technology of ignition temperature and measuring device, which is applied in blasting and other directions, can solve problems that are not conducive to the health of the operator, unsafe, and impossible to verify, and achieve the effect of humanized experimental operation, stable and reliable performance, and safe operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

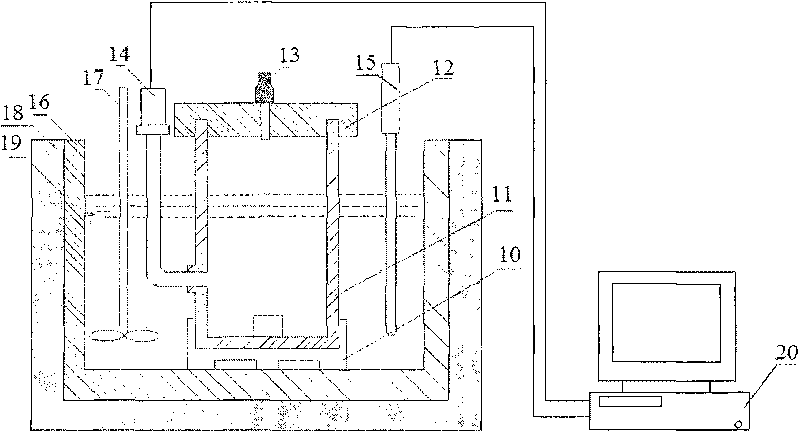

[0022] Such as figure 2 As shown, the present invention adopts a new calorific value testing device, including a base 10, a burner body 11, a burner top cover 12, an intake and exhaust valve 13, a pressure measuring unit 14, a temperature measuring unit 15, an automatic control Warm heating device 16, stirring device 17, heat insulation jacket 18, heating medium 19 and computer 20. The burner body is a thick-walled cylinder with a volume of 300 ml. The lower end is closed and the upper end is open. One end of the opening is connected with a top cover 12. The upper end of the burner body is sealed with the top cover 12. A base 10 is placed at the bottom of the burner. The base 10 is thick It is a sheet metal ring of 1mm. The inner diameter of the ring fits with the gap of the burner body. The height is 30mm. The ring is divided into 6 equal parts, and the lower part is cut along 6 equal parts to a height of 15mm. The burner placed in the ring, the base is in contact with the ...

Embodiment 2

[0024] Such as Figure 5As shown, the present invention adopts a new calorific value testing device, including a base 10, a burner body 11, a burner top cover 12, an intake and exhaust valve 13, a pressure measuring unit 14, a temperature measuring unit 15, an automatic control Warm heating device 16, stirring device 17, heat insulation jacket 18, heating medium 19 and computer 20. The burner body is a thick-walled cylinder with a volume of 300 ml. The lower end is closed and the upper end is open. One end of the opening is connected with a top cover 12. The upper end of the burner body is sealed with the top cover 12. A base 10 is placed at the bottom of the burner. The base 10 is thick It is a sheet metal ring of 1mm. The inner diameter of the ring fits with the gap of the burner body. The height is 30mm. The ring is divided into 6 equal parts, and the lower part is cut along 6 equal parts to a height of 15mm. The burner placed in the ring, the base is in contact with the b...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Melting point | aaaaa | aaaaa |

| Boiling point | aaaaa | aaaaa |

| Volume | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com